Burnham V9A User Manual

Page 28

28

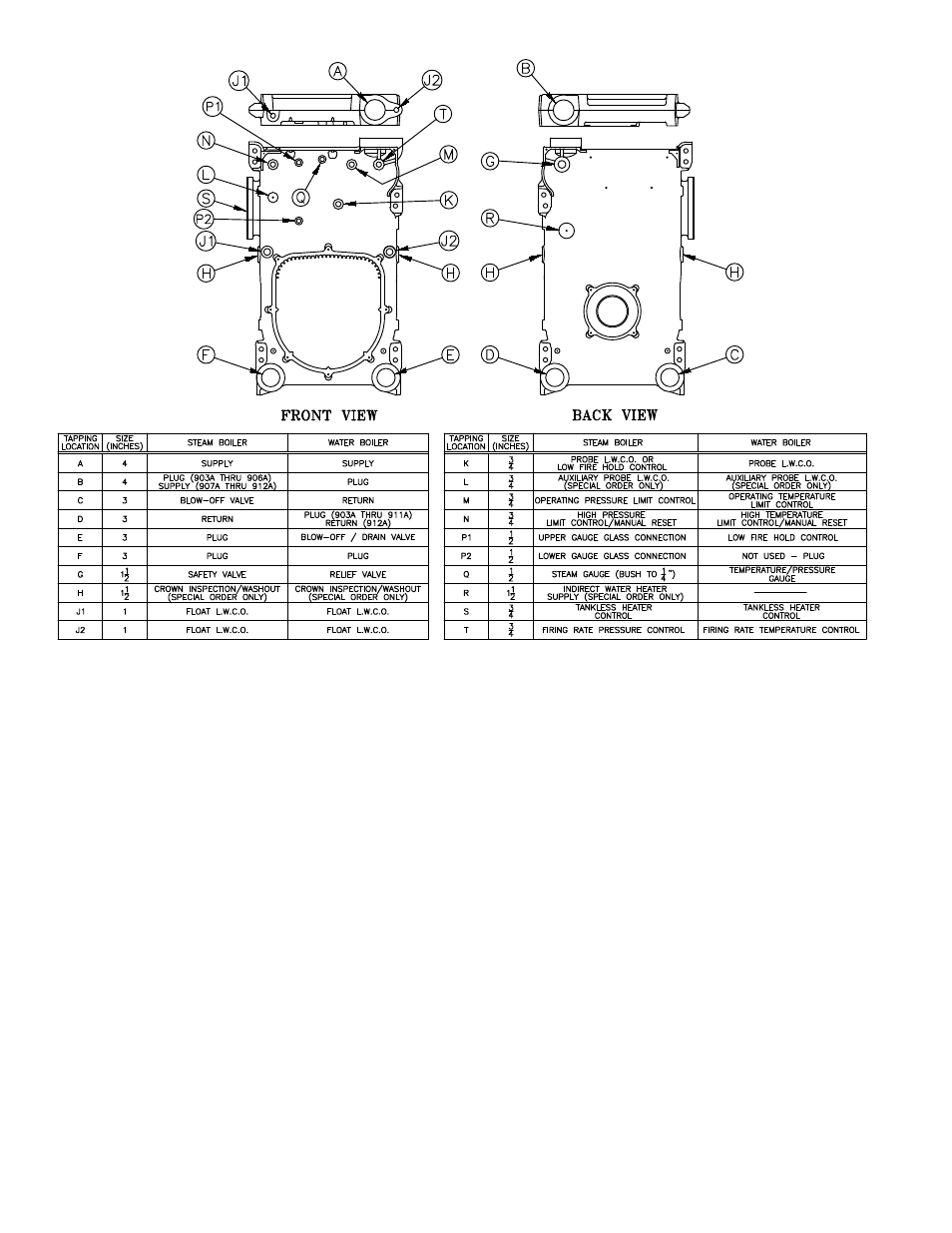

Figure 24: Purpose of Tappings

J.

BURNER INSTALLATION

Refer to burner manufacturer’s installation manual

for proper installation, fuel piping, wiring, burner

adjustment, burner start-up and service instructions.

Consult Section VI of this manual for burner

specifications and burner settings.

K.

PACKAGED BOILER

1. The packaged boiler comes on it’s own shipping

skid (see Figure 25) and the assembled block is

hydrostatically tested at the factory. Once the boiler

is in it’s final position, perform another hydrostatic

test at 1½ times the working pressure of the boiler.

Before boiler is put into service, all draw up rod nuts

should be loosened and then retighten to finger tight

plus 1/2 turn. The shipping skid can be used as a

housekeeping pad unless local codes say otherwise.

All controls are pre-wired down to the burner. If

burner is equipped with a lead lag panel, lead lag

controls will be shipped loose for header mounting.

The power can be supplied to the burner if equipped

with a control panel. If burner has no panel, the

power is supplied to the J-box on the front jacket.

2. SUPPLY CONNECTIONS - Removal of top

jacket is not required to connect the supply riser(s),

however one may find it easier. Refer to Figure

26 or 27 for water boilers and Figure 32 for steam

boilers.

3. RETURN CONNECTIONS - The boiler is secured

to the shipping skid with U bolts and 3” shipping

nipples. Remove the bolts and nipples. Using

3” plugs and an appropriate pipe sealant, plug

the unused return connections according to the

minimum piping recommendations. Refer to Figure

26 or 27 for water boilers and Figure 32 for steam

boilers.

4. If the boiler burner unit was factory fire tested, the

burner was adjusted to approximately 10% CO2

(gas) or 12% CO2 (oil) with an over fire pressure as

listed in the Burner Specifications, Section VI of this

manual. Final adjustments should be made once the

unit is installed and adjusted.