Caution, Warning – Burnham V9A User Manual

Page 18

18

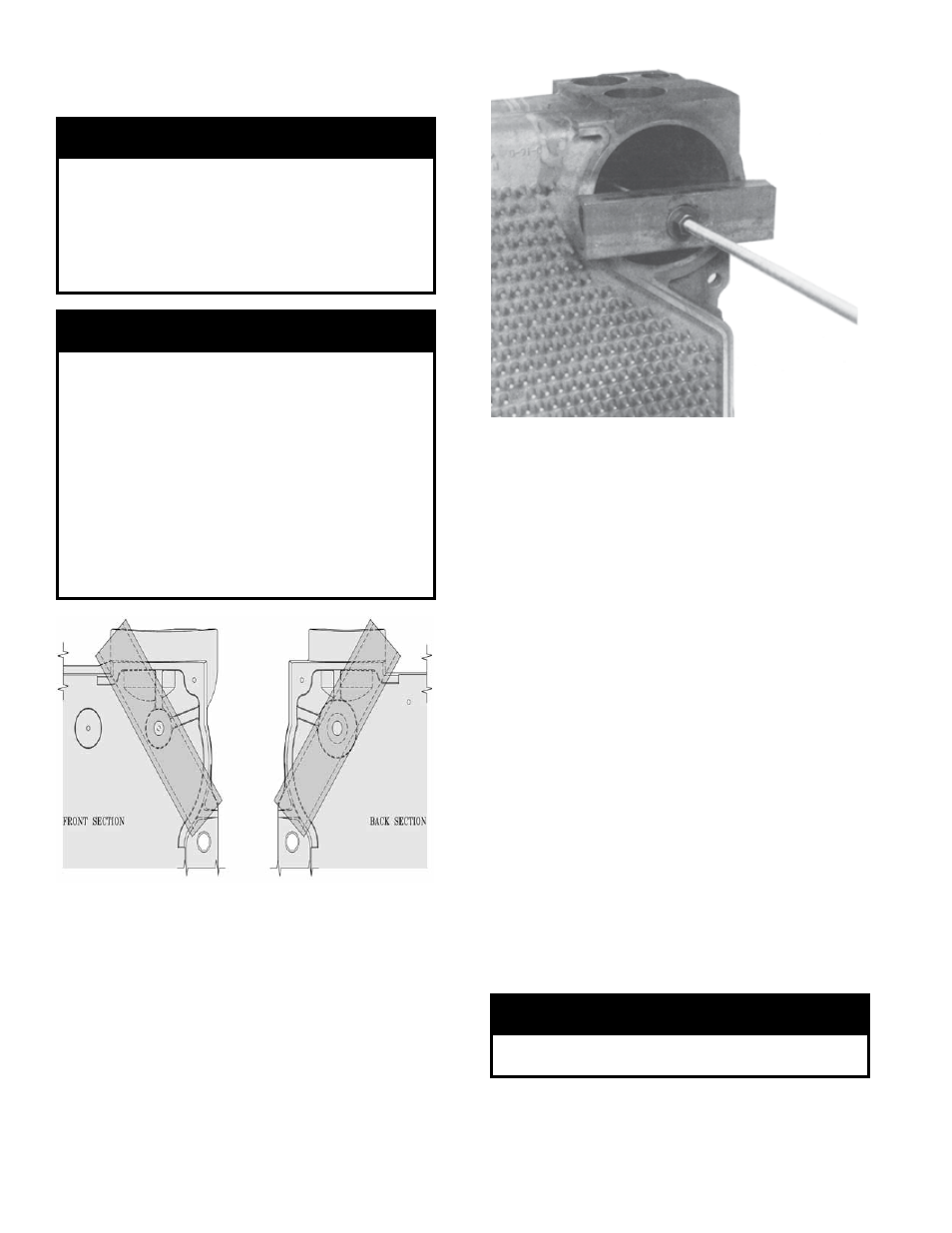

draw-up rod clamps on the other. These items

are all located in the Draw-Up Kit.

See Figure 12.

CAUTION

Do not apply pressure directly on threaded

tappings on front and rear sections with draw-up

channels during assembly procedures.

Rods should be approximately centered in

openings so that rods and couplings (when

used) do not drag on pipe thread in end section

tappings.

WARNING

READ THE STATEMENTS BELOW BEFORE

ATTEMPTING TO USE HYDRAULIC EQUIPMENT.

• Release pressure in ram pumps before

attempting to remove clamps.

• Do not stand in line with draw-up rods at either

end when hydraulic pressure is being applied.

As a safety measure, ends of draw-up rods

should be covered while sections are being

drawn in case rods should snap while under

tension.

• Do not operate ram against draw-up coupling.

• Do not operate pump after ram has reached

stroke limit.

e. Draw-Up Sections

Use hydraulic rams to draw up sections by

applying pressure alternately on the draw-up

rods. When rams reach stroke limit, release

pressure in ram pumps and then move clamps to

new position.

f. Continue to draw-up until all sections make

contact at the ground joints.

g. After all sections have been drawn up, but before

removing the hydraulic rams and draw-up rods,

the 9¾” long tie rods must be installed.

Figure 10: Front and Rear Section Channel

Block Positions (Hydraulic Draw-Up)

Figure 11: Center Section Channel Block Position

(Partial Block Draw-Up)

The large draw-up rod lugs with dual holes cast

in the four (4) corners of each casting. Starting

with the upper holes in the back section, install

four (4) 5/8” x 9¾” long tie rods along with

washers and nuts. Continue installing the tie

rods alternating from the upper to lower set

of holes in draw-up lugs until front section is

secured. Be certain that all sections are drawn

up IRON TO IRON at all three nipple ports.

h. Excess length of draw-up rods must not extend

beyond front and rear section to ensure proper fit

of jacket, adjust accordingly. Tighten all tie rod

nuts until finger tight. Then tighten them an

additional ½ turn with a wrench.

C.

HYDROSTATIC TEST — After the boiler sections

have been assembled, it is essential that the boiler be

hydrostatically tested before the canopy, flue cover

plates, jacket, or piping is installed.

1. Tankless Heater Installation

If boiler is ordered with tankless heaters, install

heaters with the gaskets provided. Table IV gives

the maximum number of heaters permissible per

assembly and the heater ratings.

2. Plug all boiler tappings and fill boiler completely

with cold water.

CAUTION

DO NOT install gauge until after hydrostatic

testing the boiler. Gauge failure may result.

3. All completed boilers must satisfactorily pass the

prescribed hydrostatic test.