Warning, Notice – Burnham V9A User Manual

Page 11

11

WARNING

Failure to supply adequate air to the boiler will

result in unsafe boiler operation.

C.

PROVIDE AIR SUPPLY AND VENTILATION to

accommodate proper combustion.

For commercial and industrial equipment, permanent

facilities for supplying an ample amount of outside air

shall be provided in accordance with the following.

For boiler rooms adjacent to outside walls, and where

combustion air is provided by natural ventilation from

the outside, there shall be a permanent air supply inlet

having a total free area of not less than 1 sq. inch per

4,000 Btu per hr. (35 sq. inch per gallon per hour)

(5.5 cm

2

per kw.) of total input rating of the burner or

burners and in no case less than 35 sq. inch (0.425m

2

).

For boiler rooms not adjacent to outside walls, the

combustion air shall be supplied in a manner acceptable

to the authority having jurisdiction.

1. In the absence of local requirements, the confined

space shall be provided with two permanent

openings, one in or near the top of the room and one

near the bottom. The openings shall communicate

by means of ducts, with the outdoors or to such

spaces (crawl or attic) that communicate with the

outdoors.

a. Where communicating by means of vertical

ducts, each opening shall have a free area of not

less than 1 sq. inch per 4,000 Btuh (35 sq. inch

per gph) (5.5 cm

2

per kw) of total input rating of

all appliances in the enclosure.

b. If horizontal ducts are used, each opening shall

have a free area of not less than 1 sq. inch

per 2,000 Btuh (70 sq. inch per gph.) (11 cm

2

per kw) of total input of all appliances in the

enclosure.

D.

CHIMNEY OR VENT

NOTICE

When a V9A gas fired boiler is connected to

a venting system that is designed so that it

will operate under a negative pressure, the

use of Type C, B, or other manufactured vent

systems designed for negative pressure is

acceptable.

When a V9A oil fired or combination gas/oil

fired boiler is connected to a venting system

that is designed so that it will operate under

a negative pressure, the use of Type C, L or

other manufactured vent systems designed

for negative pressure is acceptable.

Unlined masonry chimneys are not accept-

able. Lined masonry chimneys are acceptable

with the appropriate vent connectors using

materials described above.

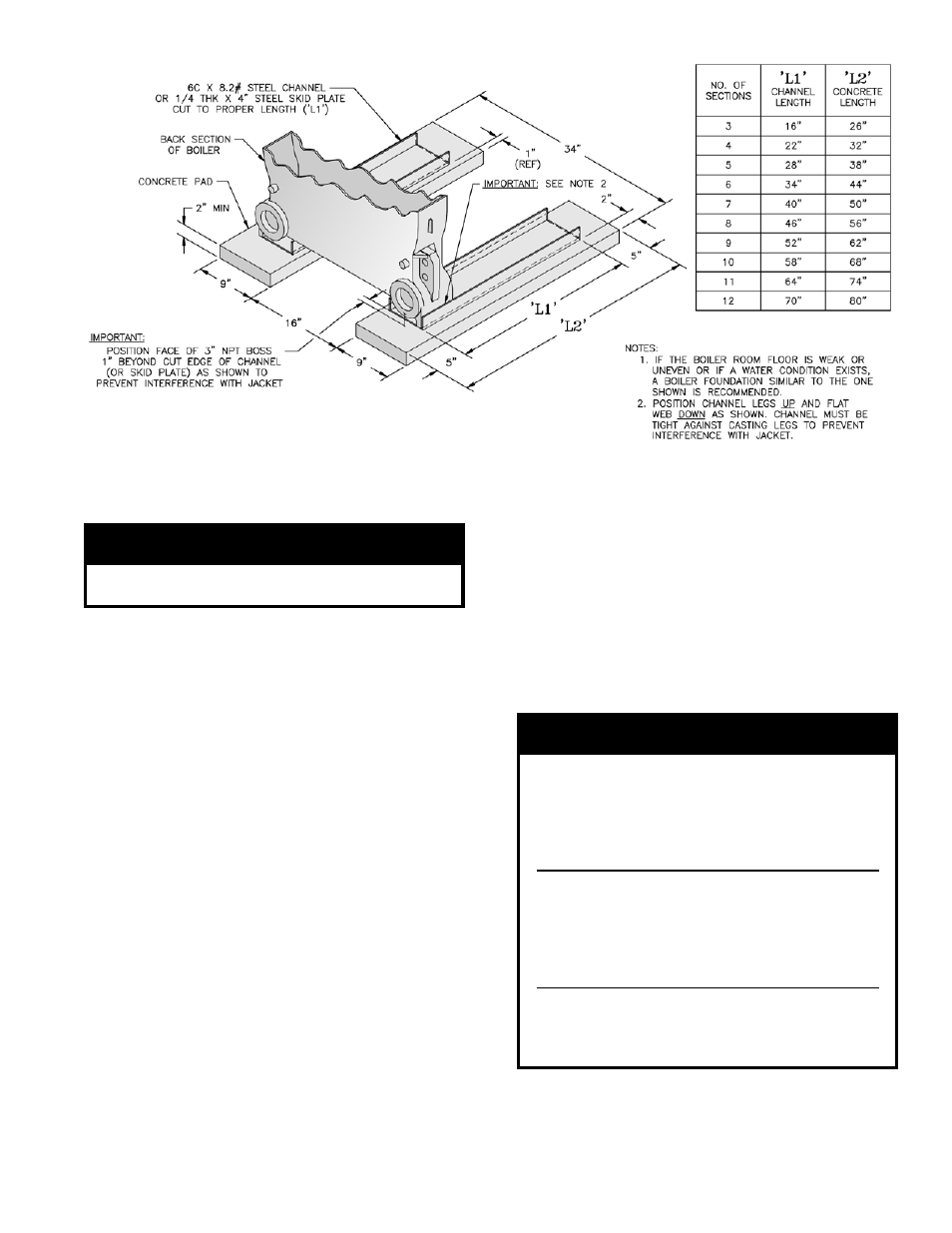

Figure 2: Boiler Foundation