Warning – Burnham V9A User Manual

Page 12

12

WARNING

When a V9A gas fired boiler is connected

to a venting system that is designed so that

it will operate under a positive pressure,

manufactured vent systems, designed and

approved for positive pressure application per

UL1738, must be used (for example, Van-Packer

model CS, Protech Model FasNSeal / FasNSeal

W2, Heatfab Saf-T-Vent or equivalent).

When a V9A oil fired or combination gas/oil

fired boiler is connected to a venting system

that is designed so that it will operate un-

der a positive pressure, manufactured vent

systems, designed and approved for posi-

tive pressure application, must be used (for

example, Selkirk Metalbestos Model PS / IPS,

Van-Packer Model ES or equivalent).

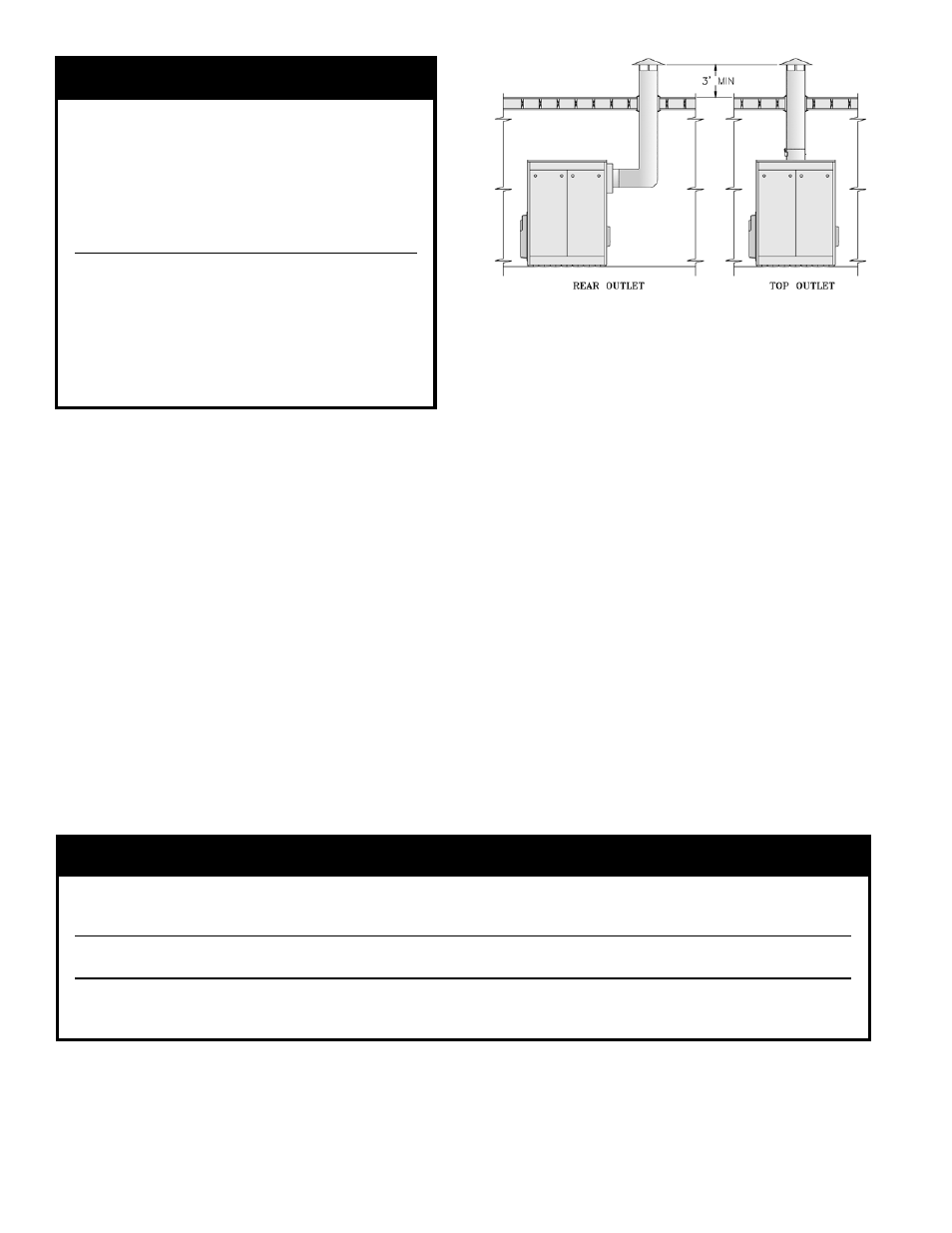

The V9A Series boiler is designed for forced draft

firing and may be used with a conventional natural draft

stack (15’ minimum height) or a stub vent, sometimes

called a diesel stack (see Figure 3a). See Table I for

the proper vent outlet size. For low silhouette vent

terminations, see Figure 3b. Draft controls are not

normally required, although they may be used on

installations where a natural draft stack is used or on

multiple boiler installations with a common stack. The

boiler is provided with a breeching damper, which

should be adjusted to maintain a positive pressure of

0.1” W.C. in the vent connector box during burner high

fire operation (see breeching pressure sensing port in

Figure 1).

If the venting system is designed for positive or forced

draft venting, the boiler, vent connector and stack will

operate under positive pressure. Gas tight vent systems

designed for pressure systems must be used to prevent

flue by-product leakage. The vent height is usually

limited to prevent negative draft, typically three (3)

feet above the roof line (see Figure 3a). The damper

shall be adjusted to maintain a positive pressure of

0.1” W.C. in the vent connector box during burner high

fire operation (see breeching pressure sensing port in

Figure 1).

If the venting system is designed for negative pressure

(natural draft), the boiler still operates with positive

pressure in the chamber and up to the fixed damper on

the flue collar. However, if the venting system is larger

than what is required, the stack will provide a surplus

draft (or negative pressure) that may require the use of

a barometric damper to maintain the positive 0.1” W.C.

pressure at the flue outlet. Multiple forced draft boiler

stacks should always be designed as negative to ensure

the products of combustion do not exit a boiler that is

not firing.

WARNING

Venting instructions are recommendations only. Consult a venting expert on the design of a specific

vent system for your application. The ASHRAE Venting Guide and The National Fuel Gas Code, NFPA

54 should be considered in all venting systems.

Conventional vent material may not be suitable for the application. Flue gases can leak carbon

monoxide from the joints on these materials and can result in severe personal injury or death.

Installations having long horizontal runs or an excessive amount of tees or elbows will restrict the flow

of combustion gases and can result in condensation, flue gas leakage of carbon monoxide, resulting in

severe personal injury or death.

Figure 3a: Typical Arrangement for Stub Vent