Warning – Burnham V9A User Manual

Page 17

17

WARNING

When tightening the draw-up nuts, DO NOT

EXCEED 150 FT-LB OF TORQUE. If the maximum

torque limit has been reached and a gap greater

than .025” still exists between the sections,

consult the regional office.

KEEP NIPPLES ALIGNED WITH NIPPLE

PORTS. If necessary, tap edge of nipples lightly

with a blunt tool or rod to keep nipples from

cocking while sections are being drawn-up. DO

NOT DRAW UP SECTION WHEN NIPPLES

ARE COCKED. If the torque required becomes

excessive, periodically place a heavy block of

wood over each nipple port and strike as squarely

as possible with several blows to relieve tension

on the draw-up rods.

n. CONTINUE ASSEMBLING SECTIONS IN

THEIR RESPECTIVE ORDER alternating

draw-up rods from the upper to lower set of

holes in draw-up lugs (see Figure 13). Be certain

that all sections are drawn up iron-to-iron at all

three (3) nipple ports.

BE SURE TO APPLY THE SEALANT to

the groove in the ground joints between

adjacent sections as the boiler operates with a

positive pressure in the firebox and products of

combustion will escape between sections unless

the sections are properly sealed. The sealant

should be applied before each section is placed

on the assembly.

o. If a joint springs apart it must be redrawn tight

within four (4) hours of the time of application of

Silastic to that joint.

p. EXCESS LENGTH OF DRAW-UP RODS must

not extend beyond front and rear section to

ensure proper fit of jacket, adjust accordingly.

q. After all sections have been drawn up, the

draw-up rod nuts should be loosened until

finger tight and then tightened ½ turn with a

wrench.

r. Now Proceed to Paragraph C of this Section,

Hydrostatic Test.

2. ASSEMBLY OF SECTIONS (HYDRAULIC

DRAW-UP)

The entire boiler assembly may be drawn up at one

time using hydraulic draw-up equipment providing

the operation is completed within two (2) hours after

application of the sealant.

a. Repeat steps 1a through 1k under “Field

Assembled Sections (Manual Draw-Up).”

b. Continue driving sections in place (in their

respective order) until all sections are in the

assembly. Ground surfaces between adjoining

sections should be spaced 1/4” to 3/8” apart.

Spacing of more than 3/8” will limit number of

sections that can be drawn up in one unit and

could indicate cocked nipples.

WARNING

Sealant must be properly applied to ALL boiler

joints. Failure to properly seal the boiler joints

will result in combustion gas leaks through to

joint. DO NOT operate boiler with combustion

gas leaks. The sealant should be applied before

each section is placed on the assembly.

On long boiler assemblies, it may be necessary to

draw-up a partial block if the entire boiler is not

ready to be drawn-up tight within two (2) hours

of the first application of Silastic. If the block

assembly time extends overnight, the partial

block completed must be drawn-up tight before

leaving the boiler overnight. If a joint springs

out, it must be redrawn tight within four (4)

hours of first application of Silastic to the joint.

c. Insert the three (3) ¾” draw-up rods (and

couplings, if appropriate) through the tapped

holes in the rear section extending them through

the tapped holes in the front section. Be sure to

screw draw-up rods into couplings far enough to

prevent stripping threads.

d. Place a 3” x 12” lg. steel channel on each end of

the upper draw-up rod and a 3” x 8½” lg. steel

channel on each end of the lower draw-up rods.

Refer to Figures 10 and 11 for proper placement

of channel block during assembly procedures.

Install nuts and washers on one end of the draw-

up rods and the hydraulic rams, washers and

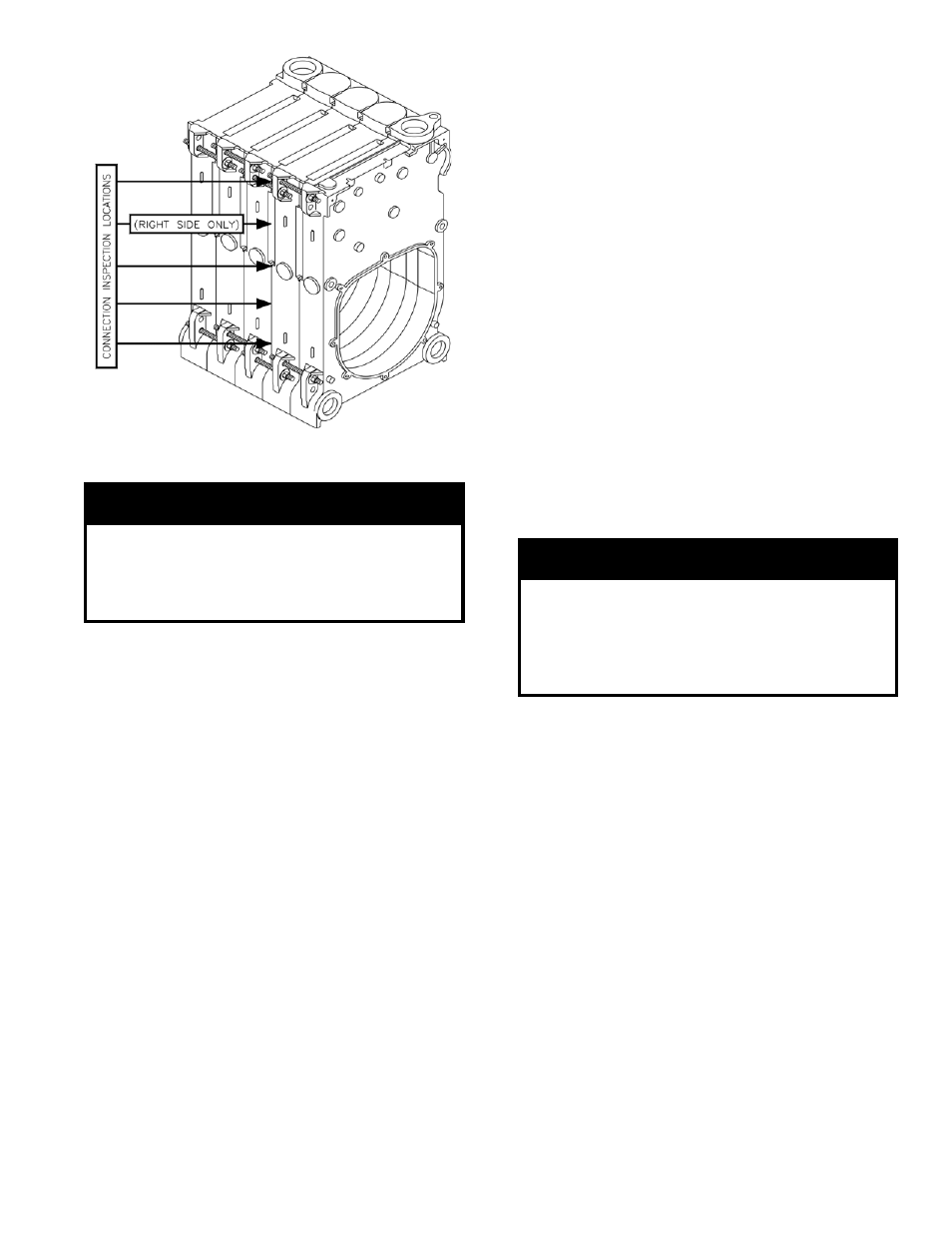

Figure 9: Connection Inspection Locations and

Manual Draw-Up Tie Rod Pattern