Caution – Burnham V9A User Manual

Page 14

14

SECTION II - CAST IRON BLOCK ASSEMBLY

A.

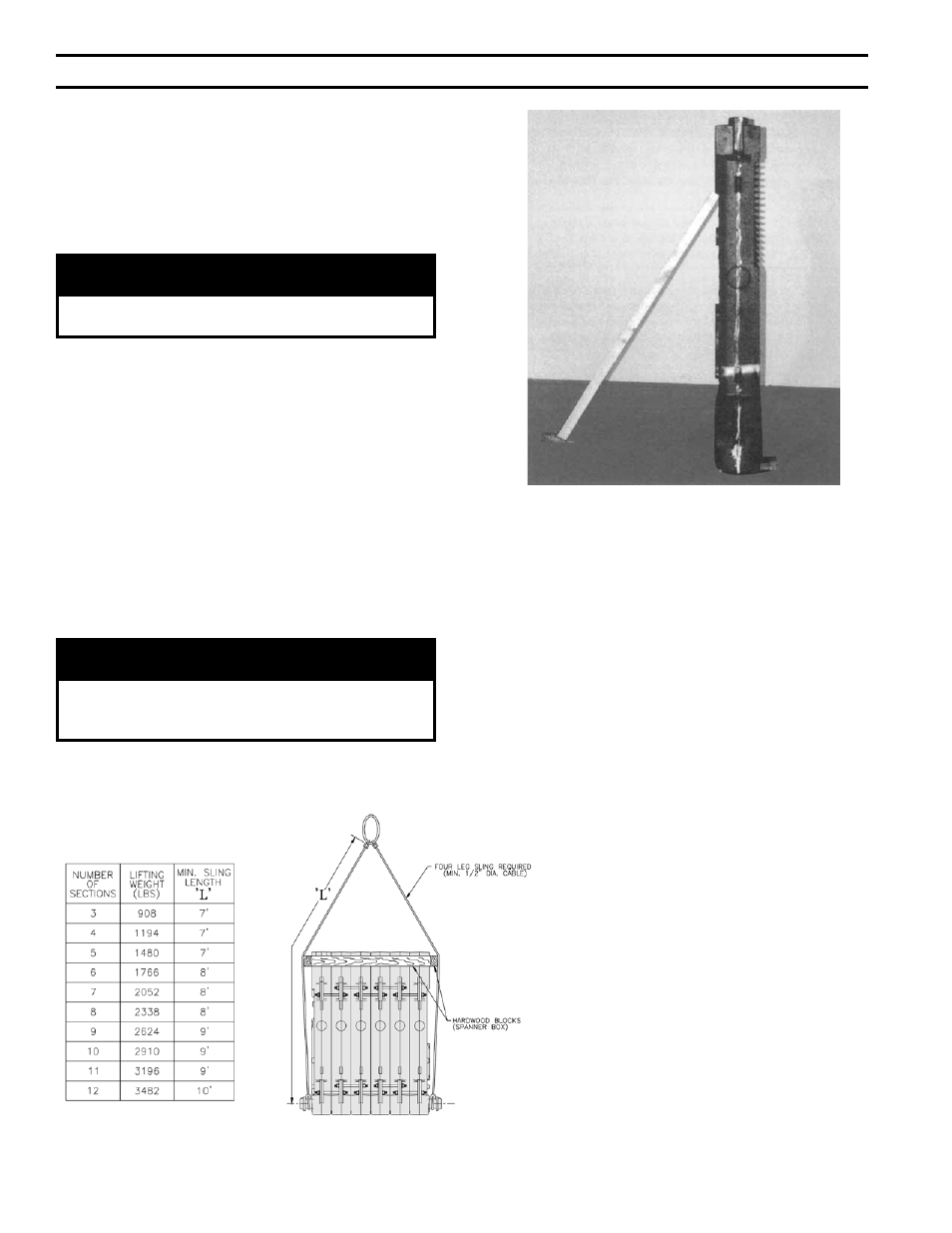

FACTORY ASSEMBLED SECTIONS — If the

boiler was ordered with factory assembled sections,

the assembly should be set in the proper location as

outlined in Section I. Lifting arrangement and weights

are given in Figure 4.

1. Proceed to Paragraph C of this Section,

“HYDROSTATIC TEST”.

CAUTION

Boiler sections must be drawn-up on perfectly

level surface or improper assembly may result.

B.

FIELD ASSEMBLED SECTIONS — If the boiler

was ordered to be field assembled, follow the assembly

procedure outlined on the following pages.

1. ASSEMBLY OF SECTIONS (MANUAL DRAW-

UP)

These sections are designed to be drawn together,

one section at a time, using the 9¾” long draw-up

rods (provided) and ordinary hand tools.

Tools required:

(1) ¾” Drive Ratchet

(1) 1-1/16” Socket

(1) 1-1/16” Combination or Open End Wrench

(1) Container of grease, oil or other appropriate

lubricant.

CAUTION

When assembling sections without hydraulic

draw-up equipment, never assemble more than

one section at a time.

a. Place the rear section in its approximate final

position, as outlined in Section I, and support it

with a suitable prop and wedges. See Figure 5.

Figure 5: Positioning of Back Section

Figure 4: Lifting Instruction

b. On size V903A only— Open target wall carton,

apply Silastic to back of target wall and secure

target wall to rear section.

c. Clean the groove in the ground joint along the

edge of the section with the wire brush.

d. Open the Boiler Assembly Carton(s) and remove

the bottle of adhesive. Using the dauber supplied

in the bottle, apply the adhesive to the groove.

Be sure to use enough adhesive to sufficiently

coat the entire groove surface. If so desired,

a multi-purpose spray adhesive (supplied by

others) may be used instead. HOWEVER,

GREAT CARE MUST BE TAKEN TO

ENSURE THAT THE ADHESIVE DOES

NOT COME IN CONTACT WITH THE

NIPPLES OR NIPPLE PORTS.

e. While the adhesive is becoming tacky, clean

nipples and nipple ports thoroughly with a de-

greasing solvent. Use the Loctite #592 provided

to lubricate the nipples and nipple ports. Apply

the lubricant to the nipples and nipple ports,

then use a brush to disperse it evenly around the

nipples and the nipple ports. Use approximately

25 ml of Loctite #592 per flueway [(1) 7” and

(2) 3” nipples and their (6) corresponding nipple

ports].

f. Drive nipples squarely into section using

block of wood and hammer, or preferably, an

aluminum head hammer. (Burnham offers a

Polyethylene Block for setting the nipples, part

number 8052601). Place block over entire

nipple edge and hit the wood with the hammer.