Caution – Burnham V9A User Manual

Page 16

16

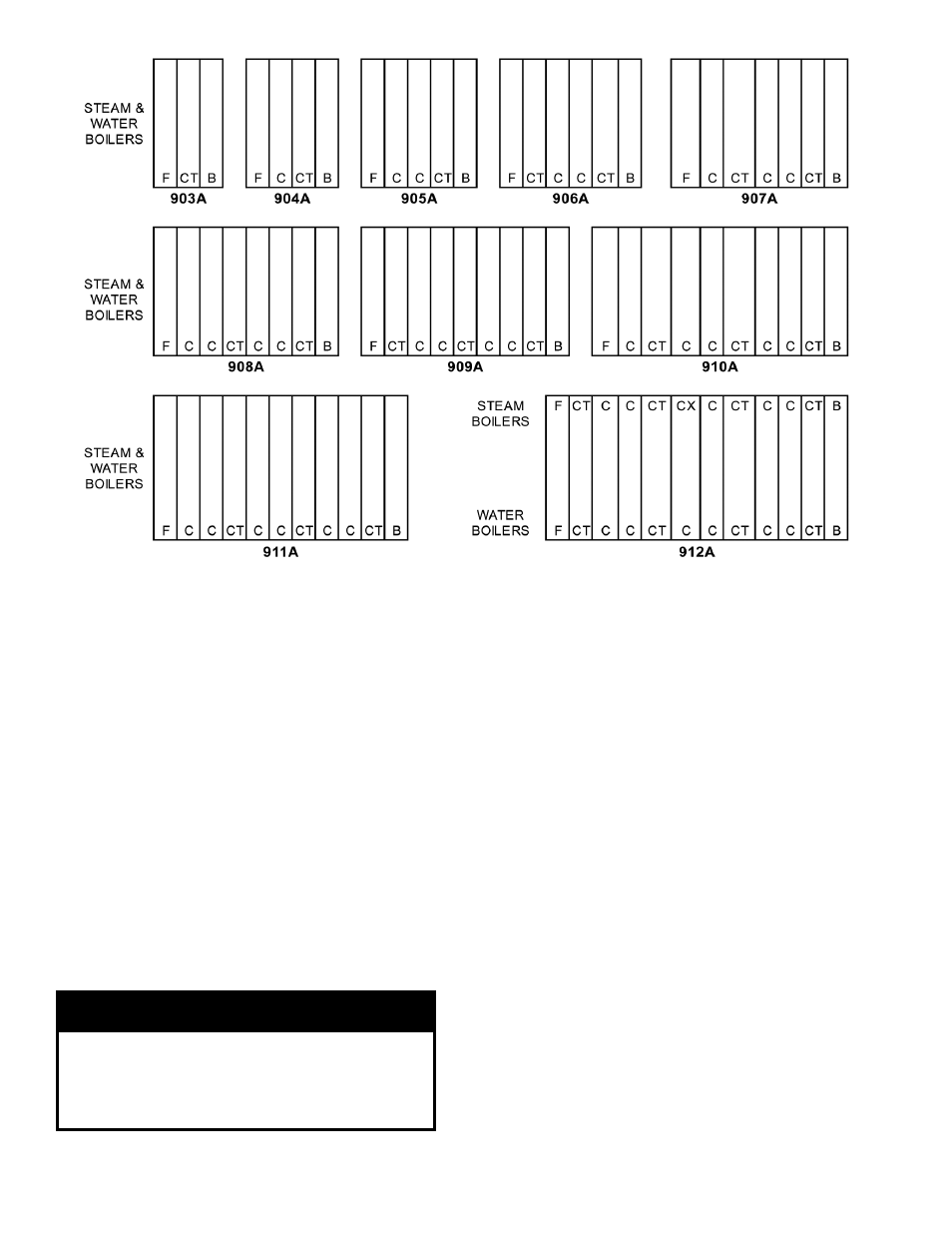

Figure 8: V9A Section Arrangement

j. Clean and lubricate nipple ports on next section

to be assembled and place on nipples previously

installed in rear section. To facilitate assembly,

it is advisable to enter the upper nipple first in

its port. Then enter the lower nipples in their

respective ports. If necessary, place a lifting bar

(crowbar) under the center of the section and lift

the nipple port onto the upper nipple.

k. Drive sections in place with a heavy block of

wood, striking blows as squarely as possible over

nipple port.

l. The large draw-up rod lugs with dual holes

are cast in the four (4) corners of each casting.

STARTING WITH THE UPPER HOLES,

install four (4) 5/8” x 9¾” long draw-up rods

along with washers and nuts (see Figure 9).

CAUTION

To avoid damage to the draw-up rod threads while

drawing up sections, apply oil or other lubricant

to tie rod threads while assembling sections to

prevent stripping of threads on rod and to make

assembling easier.

m. DRAW UP SECTION SLOWLY AND

EVENLY using an alternating pattern starting

with the upper right lug (closest to the 7” port)

and proceeding to the lower left , lower right

and finishing with upper left lug. When you

start, grind surfaces between adjoining sections

should be approximately 3/8” apart. Use

three (3) or four (4) passes at tightening the

four (4) draw-up rods a little at a time so that

sections are pulled up evenly. During the last

pass, pay close attention to the silastic sealant

as it squeezes when the sections come in close

contact. The silastic sealant should continue

to squeeze out wafer thin until the sections are

connected metal to metal. If the silastic has

stopped squeezing out from the connection and

the sections still do not appear to be drawn metal

to metal, use a feeler gauge to measure any gaps

at the locations identified in Figure 9. (Unless

specified otherwise, gaps should be measured at

these locations on both sides of the sections.) A

maximum gap of .025” is acceptable. Measure

gaps at the outer edge of the connection only,

making sure not to puncture the gasket created

by the silastic and rope.

NOTES: FOR BOILERS LESS TANKLESS HEATER, REPLACE THE "CT" SECTIONS WITH "C" SECTIONS.

TANKLESS SECTIONS: IF BOILER CAN TAKE MULTIPLE TANKLESS COILS, BUT NOT ALL

TANKLESS COILS WILL BE USED, INSTALL COILS TOWARDS BACK OF BOILER, FOLLOWING

SECTION ARRANGEMENT CHART.