Bosch 8-Dec User Manual

Page 343

LSN Peripherals | LSN Smoke | 335

Interference effects from daylight and commercial lighting

sources are filtered out with an optical daylight filter and by

the use of electronic filtering and phase-locked rectification

(ambient light stability: glare test DIN EN 54‑7).

The various light-emitting and photo diodes of the sensor

are individually controlled by the detector electronics.

Consequently, signal combinations are produced that are

independent of each other and ideally suitable for the

detection of smoke, which makes it possible to differentiate

between smoke and interference agents (insects, objects).

In addition, the time characteristics and the correlation of

the optical sensor signals for the fire or interference

detection are evaluated.

Moreover, plausibility checking of the various signals makes

it possible to detect errors in the analysis electronics and

the LEDs.

Chemical sensor (CO gas sensor)

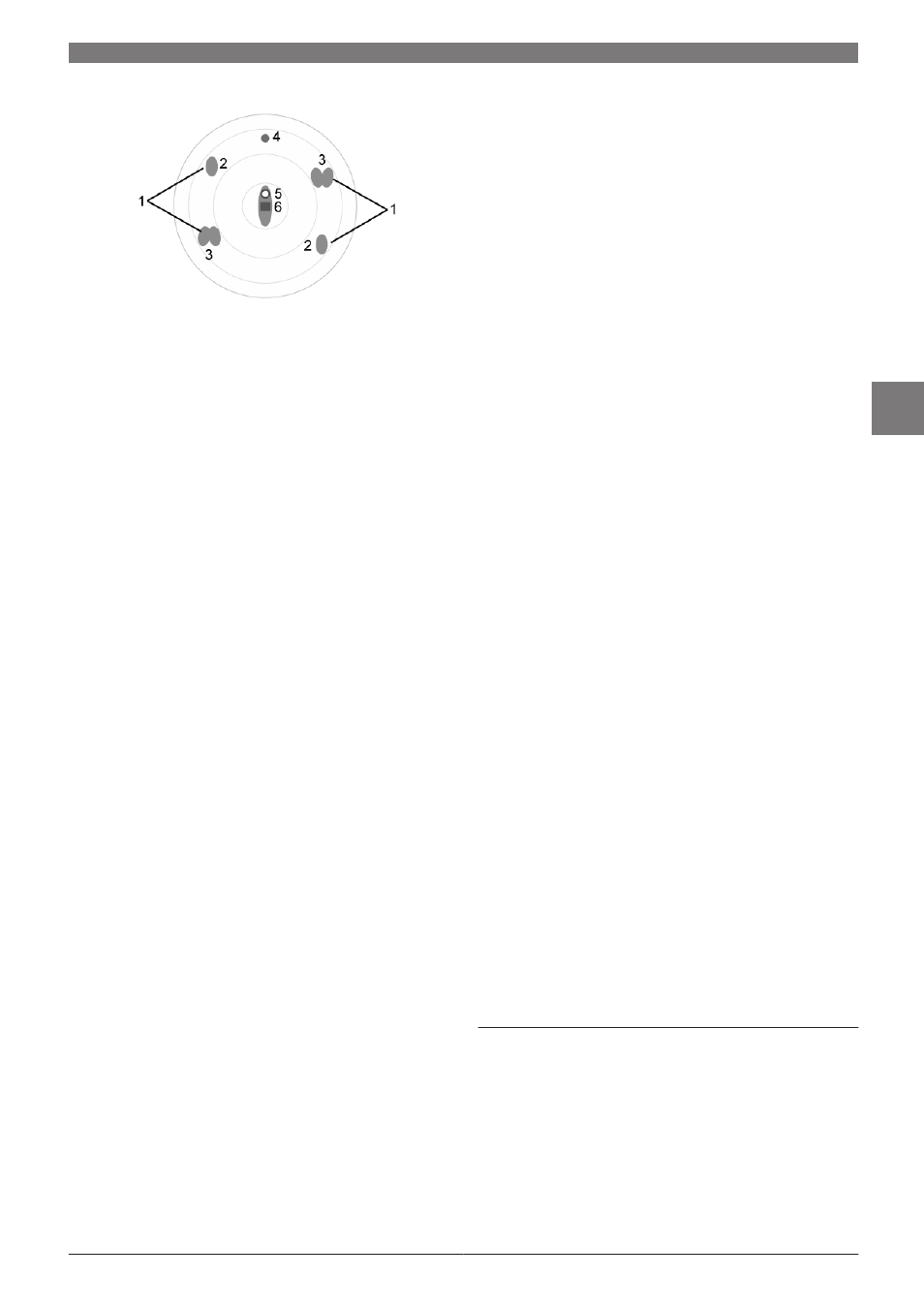

The gas sensor (4) detects mainly the carbon monoxide

(CO) that is produced by a fire, but it also detects hydrogen

(H) and nitrogen monoxide (NO).

The basic measuring principle is CO oxidation on an

electrode and the measurable current that arises from this.

The sensor signal value is proportional to the concentration

of gas.

The gas sensor delivers additional information to effectively

suppress deceptive values.

The CO sensor is monitored by measuring the internal

capacity. If the capacity lies outside the permitted range, an

error message is output on the fire panel. In this case, the

detector continues to operate purely as a scattered light

smoke detector.

Depending on the service life of the gas sensor, the

FAP‑OC 520 Fire Detector switches off the C sensors after

five years of operation. The detector will continue to

function as an O detector. The detector should then be

exchanged immediately in order to be able to keep using

the higher reliability of detection of the OC detector.

Pollution sensor

The contamination level on the detector surface is

continually measured by the pollution sensor (6); the result

is evaluated and indicated in three stages on the fire panel.

Contamination of the detector surface leads to active

adaptation of the threshold (drift compensation) and to a

fault indication in the case of heavy contamination.

Improved LSN features

The 520 Series Fire Detectors offer all the features of the

improved LSN technology:

•

Flexible network structures, including "T-tapping"

without additional elements

•

Up to 254 LSN improved elements per loop or stub line

•

Automatic or manual detector addressing selectable via

rotary switch, in each case with or without auto-

detection

•

Power supply for connected elements via LSN bus up to

300 mA

•

Unscreened fire detection cable can be used

•

Cable length up to 1000 m

•

Downwards compatibility to existing LSN systems and

control panels.

In addition, the FAP‑520 Fire Detectors offer all the

established benefits of LSN technology. The following data

can be read out for each configured detector:

•

Serial number

•

Contamination level of the optical section,

•

Operating hours

•

Current analog values.

In the event of an alarm, individual detector identification

is transmitted to the fire panel.

The sensor is self-monitoring. The following errors are

indicated on the fire panel:

•

Failure of the evaluation electronics or one of the LEDs

on the optical sensor

•

Heavy contamination (instead of false alarm)

•

Failure of the CO sensor (in the case of FAP‑OC 520).

Further performance characteristics

Various operating states are indicated on the detector by

means of a clearly visible two-color LED. In the event of an

alarm, the LED flashes red.

The control of an external detector alarm display is

possible.

Preservation of the LSN loop function is guaranteed in the

event of wire interruption or short circuit by means of

integrated isolators.

The innovative detector locking, which operates on the

ballpoint-pen principle, provides fast and simple insertion

and replacement of the detector. We recommend the

specially developed FAA‑500‑RTL exchanger device,

especially in the case of high installation heights.

To allow convenient detector testing, the FAA‑500‑TTL test

adapter with magnet and additional service accessories is

available. The magnet triggers a reed contact, which sets

the detector in test mode.

Certifications and Approvals

Complies with

•

EN54-7:2000/A1:2002/A2:2006

•

EN54-17:2005

www.boschsecurity.com

Bosch Security Systems B.V.

6