Pfannenberg DTI 6x01 User Manual

Page 18

GB

085 408 121a

18/60

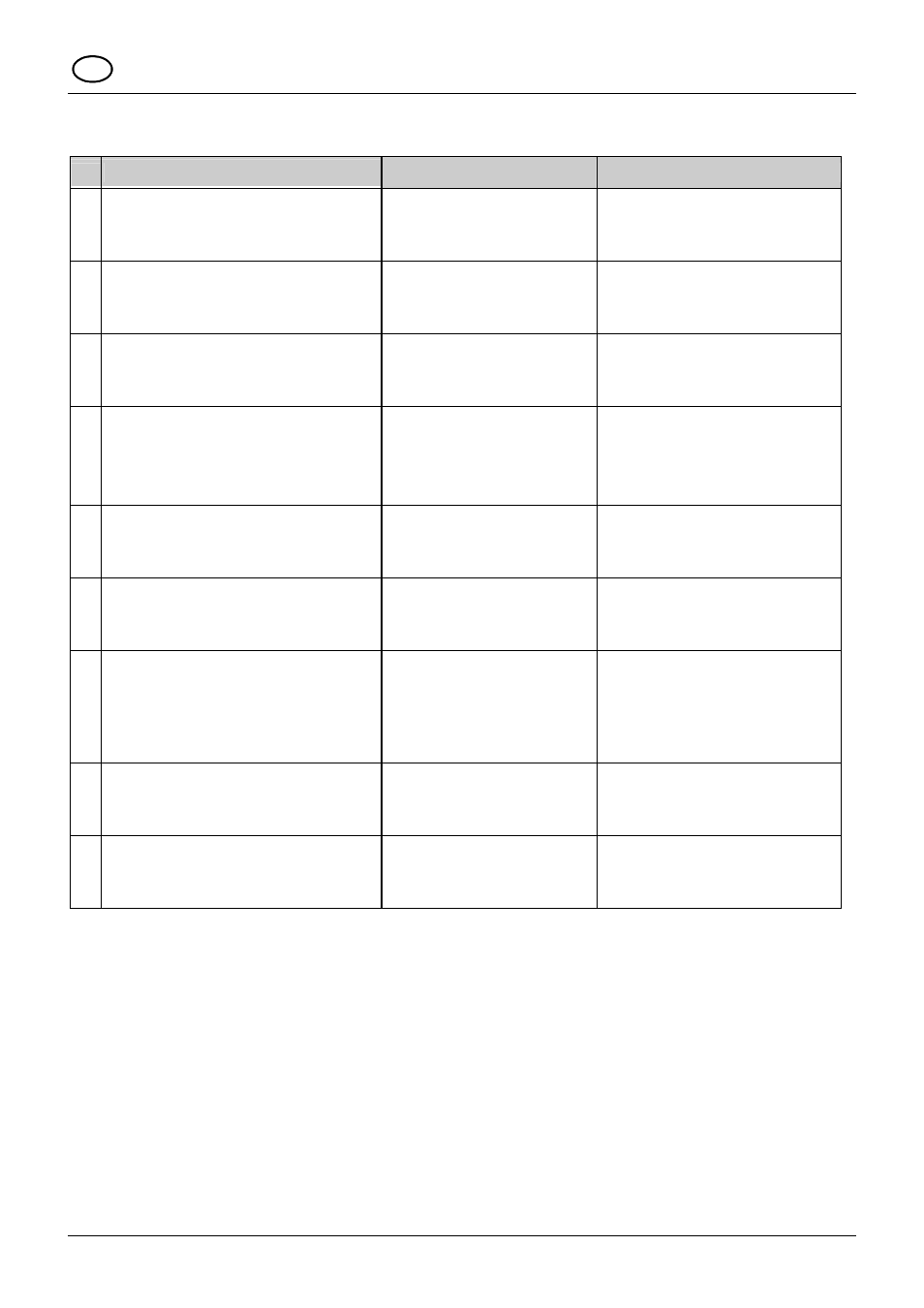

13.4 Pfannenberg units with Standard-Controller

The following table describes the technical cause as well as the fault remedy as a function of the unit characteristics.

Pos

Unit characteristics

Technical causes

Fault remedy

1 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

OFF

OFF

OFF

OFF

open

There is no supply of voltage to the unit. Check back-up fuse and/or connect supply

voltage

2 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

ON

ON

ON

flashing (seq. 3)

open

The test mode of the unit is active. This

mode is left automatically at the latest

after 60 s.

The unit switches to test mode once after

each new connection to the power supply. No

remedy of fault necessary.

3 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

OFF

OFF

OFF

flashing (seq. 1)

closed

The input for the door limit switch is

open e.g. as a result of a switch cabinet

door not closed or a bridge not set.

Insert link, close door contact switch or, with

an engaged door contact switch, close the

door

4 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

OFF

ON

OFF

flashing (seq. 2)

open

High pressure pressostat or motor

protection switch has responded (over-

heating) or

Wrong connection assignment.

Compressor switches on again auto-

matically after the fault has been

remedied (cooling) with a delay of 30 s.

Clean or replace filter or clean heat ex-

changer in the external circulation. Possibly

check the power dissipation in the switch

cabinet to the installed cooling capacity of the

air conditioner.

Check the connection assignment, see chap-

ter 8.4 (incorrect phase sequence)

5 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

OFF

OFF

OFF

flashing (seq. 1)

open

Unit adjustment by means of the coding

switch on the control electronics is not

plausible.

The unit setting must be changed.

Observe the operating instructions and note

the coding key of the coding switch.

6 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

ON

ON

ON

flashing (seq. 1)

open

The upper temperature limit (T L2 ) of

the switch cabinet has been exceeded.

Clean or replace filter or clean heat ex-

changer in the external circulation. Possibly

check the power dissipation in the switch

cabinet to the installed cooling capacity of the

air conditioner.

7 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

OFF

ON

OFF

flashing (seq. 1)

open

The lower temperature limit of the

switch cabinet has been exceeded

or

the water level in the condensate collec-

tion pan is too high (only with optional

level monitoring).

Additionally install a heater or a fan-

forced heater if necessary.

Check drain for blockage or fouling. Check for

correct installation of the run-off tube. Note

that particularly much condensate is produced

if the switch cabinet is poorly sealed or the

doors are constantly open.

8 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

ON

ON

ON

flashing (seq. 2)

open

The temperature sensor TS1 is defec-

tive or has not been detected.

Replace the contact sensor TS1 or replace

the complete electronic control with a fixed-

wired temperature sensor.

Get in touch with the service department.

9 Compressor:

Internal fan:

External fan:

Status LED:

Fault signal contact:

normal control characteristics

ON

normal control characteristics

flashing (seq. 1)

open

In the switch cabinet, if a short circuit in

the air circuit* occurs, no effective

cooling of the switch cabinet is possible.

Air-conditioning is requested within

short cycle times.

Relocate the power components in the switch

cabinet or relocate the cooling unit.

Select a top-mounting cooling unit or side-

mounting cooling unit as an alternative de-

pending on the space situation.

* Air short-circuit: An air short-circuit develops, if cool air at the air outlet of the cooling unit is led by means of power components built directly in front of it in an

unfavourable way, not into the switch cabinet, but directly to the air inlet of the cooling unit. The consequence is overheating of the power components due to the

lack of cooling.

13.5 Fault not rectified?

If the fault is not rectified now, please call authorised technical personnel. ([email protected])

14 Warranty Conditions

Warranty becomes null and void:

• in case of improper usage of the unit, noncompliance with oper-

ating conditions or non observance of instructions;

• If operated in rooms in which corrosives or acids are present in

the atmosphere;

• in case of damage caused by contaminated or jammed filters;

• if a non-authorised person interrupts the cooling circulation,

modifies the unit or changes the serial number;

• in case of damage caused by transport or by accidents;

• for the exchange of parts by non-authorized personnel.

In order to maintain your warranty rights please observe the follow-

ing when returning the unit:

• Include a detailed description of the defect and the DRU(RMA)

number issued by Pfannenberg with the cooling unit.

• Enclose proof of delivery (delivery note or copy of invoice).

• Return the unit together with all accessories; use the original

packaging or packaging of equivalent quality, send the unit

freight prepaid and covered by an adequate transport insurance.

Observe the hints on transport mentioned in section 2.