Pfannenberg DTI 6x01 User Manual

Page 15

GB

085 408 121a

15/60

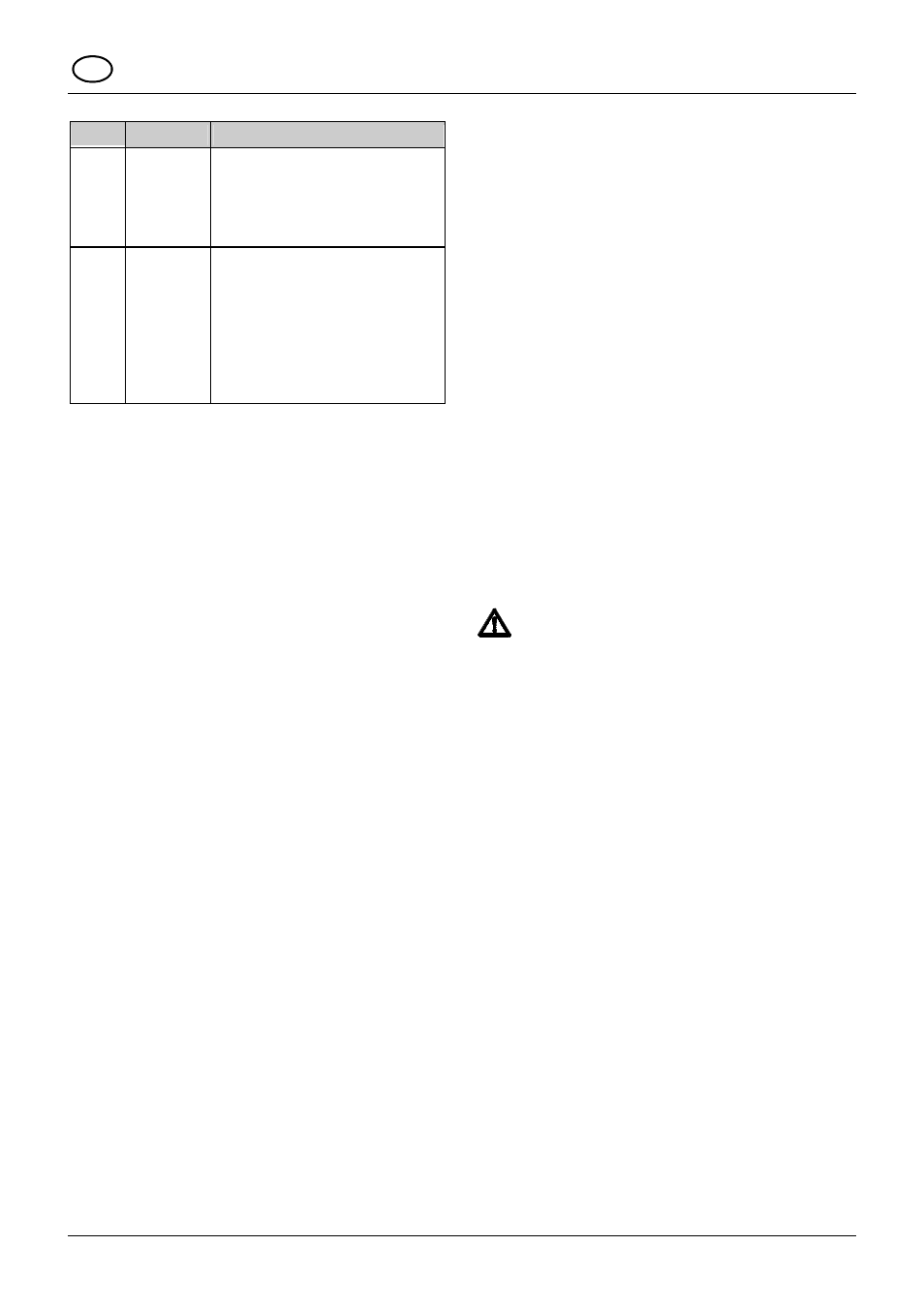

10.4 Unit characteristics

Modus Time curve

Characteristics

Start-up

mode

t = 0s - < 30s

t = 30s

t = 32s

No function

Internal fan start up

External fan and compressor start up

Flashing sequence of the status indica-

tor: "off-dark-light-dark-off".

Fault signal contact is closed.

Test

mode

t >34s – 64s. Compressor and fans remains in opera-

tion during the period. Flashing se-

quence of the status indicator:

"off-dark-light-dark-off".

Fault signal contact is open.

Should a fault arise during the test mode,

the unit goes into the fault mode and the

status indicator lights up according to the

fault state

(see chapter on Fault diagnosis)

The start-up mode is always additionally activated when the door

limit switch is closed (see Sections 10.5)

10.5 Door contact

To avoid an increased production of condensate and for safety

reasons a door limit switch should be connected to the terminals

provided (see circuit diagram in the interior panel behind the internal

fan or in the accompanying supplement sheet)

By the opening of the switch cabinet door and thus the opening of

the switch all of the motors of the cooling unit are immediately

switched off. After closing of the door the start-up mode (see Sec-

tions 10.4) is run through which ensures a restart-up of the cooling

unit with a time lag.

10.6 Centralised fault indication

The signalling of a fault in the cooling unit is effected by the breaking

of a potential-free contact (see Sections 13). In this way a cable

breakage in the fault signalling line is also signalled.

10.7 Energy mode

(Optional, only for units with Multi-Controller)

1) If the cooling unit is not in active cooling operation for 15 min-

utes, it switches to energy mode. This is shown in "Application

error" rhythm (Consequence 1) by a flashing LED and with "En"

in the display.

2) Energy mode is interrupted by a cooling command (switch

cabinet interior temperature above the target temperature, which

means the cooling unit is in active cooling mode). Cooling mode

is maintained until the target temperature (less hysteresis) is

reached. After an additional 15 minutes the device switches

back to energy mode.

3) If device errors arise in energy mode, the cooling unit will be-

have in accordance with the fault diagnosis.

4) If the target temperature (less hysteresis) is undercut at the

external temperature sensor during energy mode, the internal

fan is switched off. If the target temperature (plus hysteresis) is

exceeded at the external temperature sensor, the internal fan is

switched on.

5) As long as no error occurs in the unit, the fault message output

of the device is closed in energy mode (no error).

10.8 Multimaster – bus

(Optional, only for units with Multi-Controller)

In the multimaster configuration, cooling operation is initiated by the

cooling unit which reaches the operating threshold (Tsetp. + 2K)

first. All of the cooling units connected to the multi-master bus switch

to cooling operation. The cooling mode is terminated by the unit

which is the last to go below the operating threshold (Tsetp. - 2K).

For all cooling units which are operated in combination through a

Multi-Master control, the execution of the energy function is

switched off by the cooling command of one of the units from the

combination.

After the last cooling command, the cooling units return to energy

mode after the lapse of the set delay time

10.9 Setting possibilities

By means of a DIP switch (standard controller) or using the USB-

interface (Multi-Controller), various switch cabinet temperatures as

well as limit temperatures can be selected.

The location of the DIP switch on the control board is shown in the

circuit diagram.

The coding options are represented on the circuit diagram (Stan-

dard-Controller). The circuit diagram is adhered to the interior panel

behind the internal fan and shown in the accompanying supplement

sheet.

Starting with a particular set-temperature in the switch cabinet, an

upper limit temperature can be selected which, if exceeded, will

generate an alarm. On units with Multi-Controller, the lower tem-

perature limit can also be monitored. See accompanying supple-

ment sheet for factory settings.

Hint:

The ECoolPLANT service kit (article no.: 18310000002) can be

used in combination with a PC for optimal maintenance, diagnosis

and unit status monitoring of cooling units with multi-controllers.

The ECoolPLANT service kit is a Pfannenberg software package

that, with the aid of the provided USB-cable (type A/B), allows the

following information to be visualised:

- unit data/status

- parameter settings

- temperature recording

- error memory information

Please find more detailed information about the ECoolPLANT soft-

ware and the possibility to download the software free of charge on

the Internet at www.pfannenberg.com.

CAUTION!

Changes to the parameters of the unit set in the works may

be made only by authorised persons!

Isolate the cooling unit from the mains before changing the

DIP-switch settings. Otherwise the modified settings won't

be accepted.