Pfannenberg DTI 6x01 User Manual

Page 14

GB

085 408 121a

14/60

• No temperature control must be series-connected to the cooling

unit feed.

The fuse as indicated on the ID plate must be series-connected

as line protection.

• Power connection and repairs, if applicable, may only be carried

out by authorized trained electricians.

Power supply connection (mains):

Both mains voltage and frequency must correspond to the nominal

values indicated on the ID plate of the cooling unit.

• The installation of the power cable is not subject to any special

requirements

Attention: The cooling unit may be damaged if the

voltage is too high.

Refers to cooling units for nominal voltages 400 V/460V.

As an option, some units, different to the standard (400

V/460 V), may be connected to a different mains voltage

(For voltage range see enclosed sheet).The feed cables on

the transformer primary must be unclamped for this.

Attention! The cooling unit may be damaged due to

incorrect direction of rotation.

Before switching on the unit, check the phase sequence of

the three-phase supply in order to prevent damage to the

compressor. Direction of rotation must be to the right

(clockwise). The correct pin assignment is indicated by an il-

luminated LED in the connection area. With a flashing or

dark LED the pin assignment must be checked.

Door contact:

The door contact is supplied form the cooling unit with an extra-low

voltage (<20V, 20 mA).

• In order to avoid any disruptive influences, it is recommended

that a sheathed cable with twisted pair leads be used. The

screen can be secured on one side to the PE connection point

provided on the cooling unit.

• If the use of sheathed cables is not possible, during installation of

the cables it must be ensured that they are not routed in the im-

mediate vicinity of potential interference sources (e.g. supply

lines, components with relatively high electromagnetic emission).

WARNING: No external voltage may be applied

If no door-contact switch is used, the connecting contacts

are to be bridged.

Centralised fault indication:

For connection of the fault signal line there are 2 connection con-

tacts and/or connecting lines available (see circuit diagram on the

Technical Supplementary Sheet)

The installation of the fault signal line is not subject to any special

requirements.

WARNING: The contact may be loaded with max.

230 V, 1A.

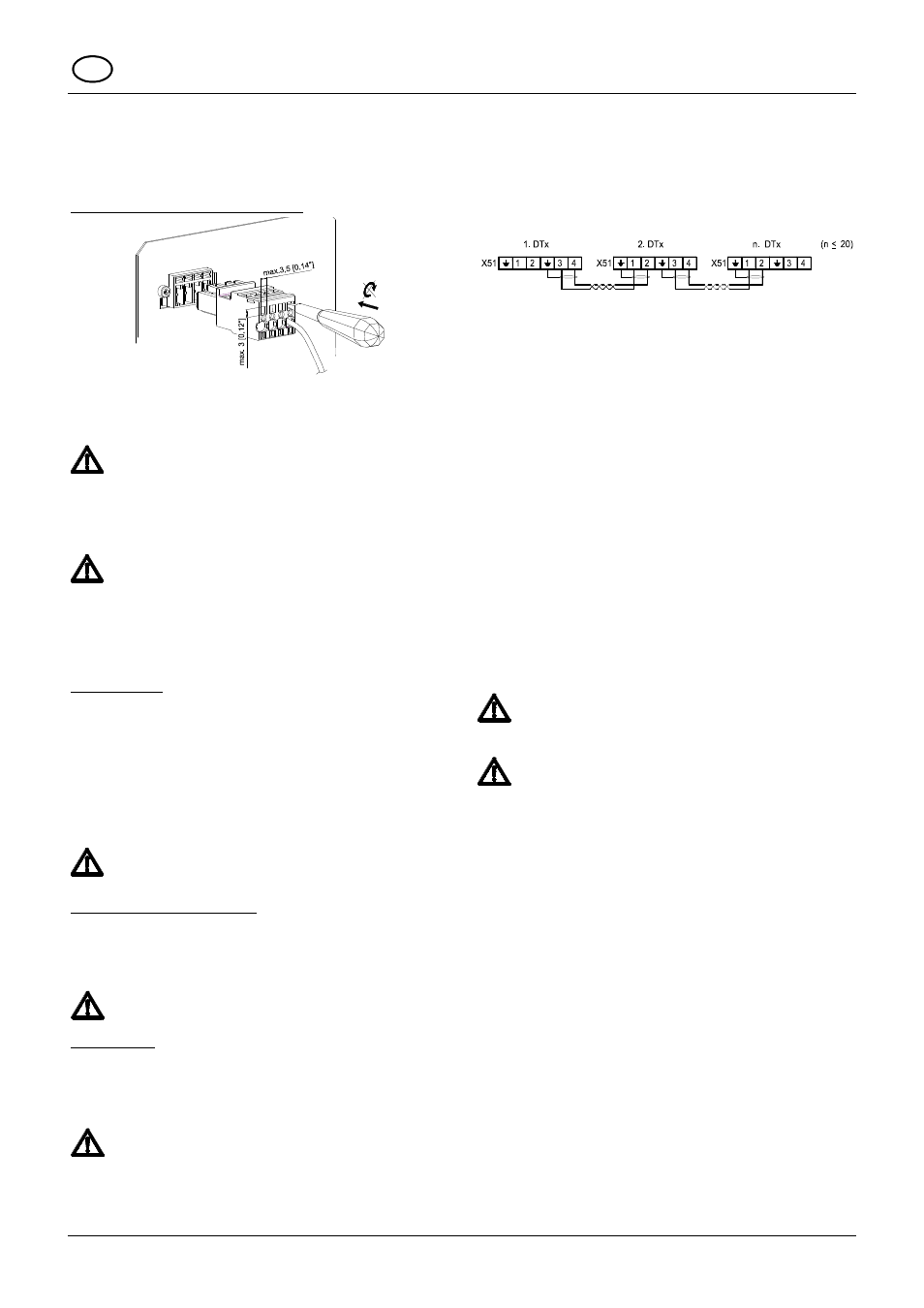

Multimaster:

(Optional, only for units with Multi-Controller)

To connect the multimaster cables there are in each case 2 con-

necting contacts (input and output-end) available (see connecting

diagram on the rear of the housing).

The contacts are supplied with low voltage (< 20 V, 20 mA) from the

cooling unit.

WARNING: No external voltage may be applied

• In order to avoid any disruptive influences, it is recommended

that a sheathed cable with twisted pair leads be used. The

sheath can be connected at both ends to the PE terminal pro-

vided on the cooling unit for the purpose.

• If the use of sheathed cables is not possible, during installation of

the cables it must be ensured that they are not routed in the im-

mediate vicinity of potential interference sources (e.g. supply

lines, components with relatively high electromagnetic emission).

• A maximum of 20 units may be controlled over the bus.

Block diagram of the Multimaster wiring

For more information see also chapter 10.8 (Multimaster – bus)

9 Operating Conditions

• Voltage must be within ± 10 % of the value indicated.

Frequency must be within ± 3 Hz of the value indicated.

• Ambient temperature must be below 55 °C (for options see

supplement).

• Use the unit such that the cooling capacity suits the actual de-

mand.

• Use refrigerant as indicated only.

• Use genuine spare parts only.

10 Putting into operation and function

10.1 General remarks

The cooling unit is provided with an electronic control system. The

drawn-in switch cabinet internal air temperature is measured by a

temperature sensor. By means of a DIP switch on the control board,

different switch cabinet temperatures as well as upper limit tempera-

tures can be selected (see accompanying supplement sheet). With

devices with Multi-Controller the adjustment takes place by means

of a USB cable and the configuration software ECoolPLANT, includ-

ing the USB driver software. Exceeding the limit temperature gener-

ates an alarm. For units with Multi-Controller, the lower temperature

limit can also be monitored.

Warning!

Ambient conditions and temperature in the switch cabinet

must be in accordance with the values indicated in the sup-

plement.

Warning! Too little heat transfer at the heat exchanger

in the external circuit (condenser)..

The cooling unit may only be operated with cover, otherwise

heat dissipation at the condenser is not sufficient, and the

cooling unit may be damaged.

Immediately after the switch-on of the service voltage, the

unit goes into the start-up/test mode. After that the evapora-

tor fan continues to run. Compressor and condenser fans

run on as required (the temperature of the switching thresh-

old (T

set

) has been reached, or are switched off (temperature

lower than switching threshold (T

set

)).

• Free discharge of any condensate produced must be provided to

ensure trouble-free operation.

10.2 Indicator elements

The cooling unit with standard controller has an operational display

in the form of an LED on the external hood of the unit. If the light of

this indicator remains on when the supply voltage is applied it shows

that the unit is in the normal operating mode. If a fault occurs or if

the unit is in the start-up or test mode, this indicator lights up in

various flashing sequences which make it easier to diagnose fault in

the unit (see Sections 10.4 and 13)

The cooling unit with multicontroller has a temperature display.

10.3 Test mode / start-up

The test mode is basically activated after renewed connection of the

supply voltage and is independent of the instantaneous ambient

conditions when the door contact is closed.

First of all the unit runs through a start-up mode lasting 30 seconds

which is followed by a test mode lasting 30 seconds.