Bell & Gossett P5002169C Series VSCS User Manual

Page 9

7

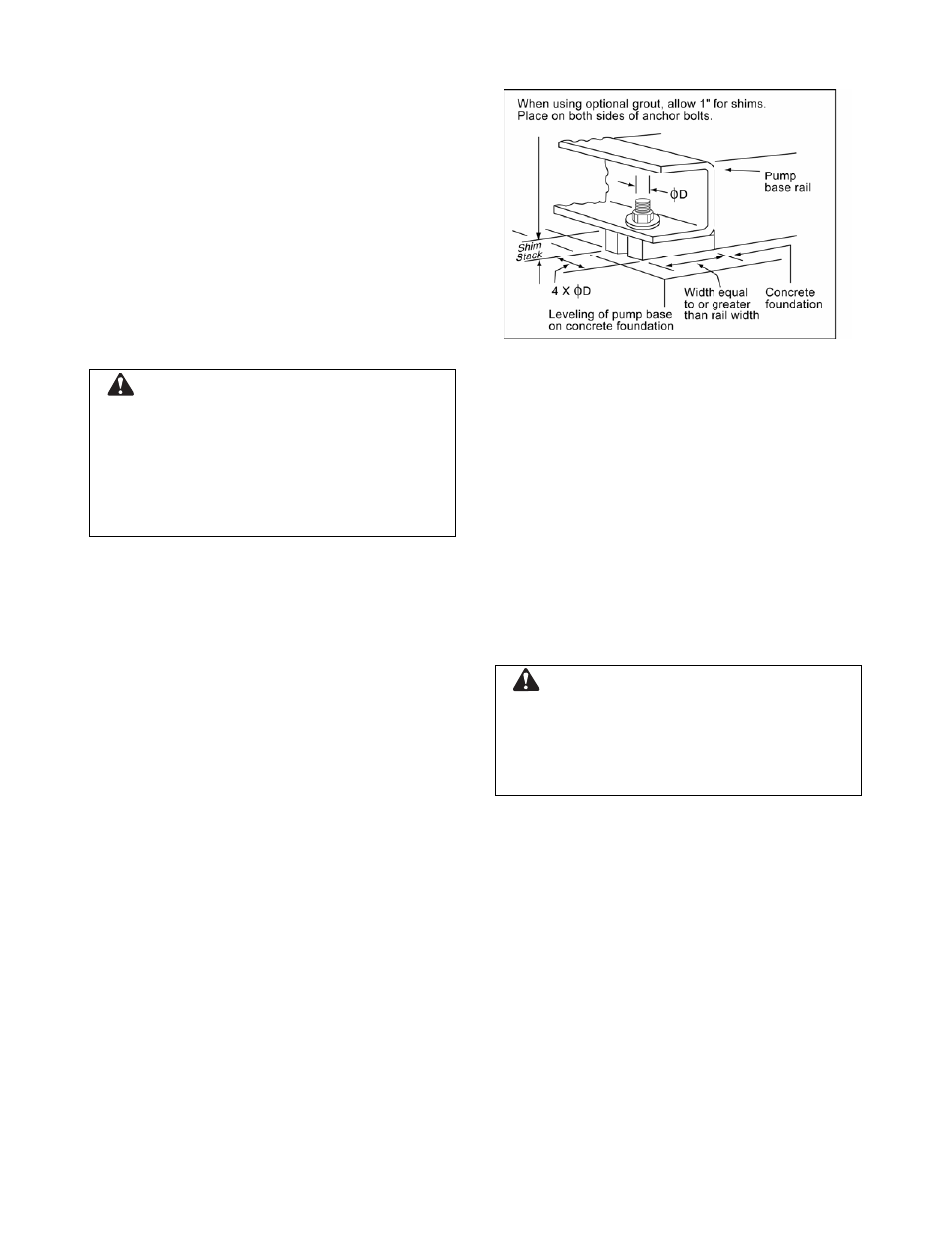

BASE PLATE SETTING

Place the pump unit on its concrete foundation,

supporting it with steel wedges or shims. The

wedges or shims should be machined and be put

on both sides of each anchor bolt to provide a

means for leveling the base. The wedge or shim

width should be equal to or greater than the base

rail width. The length of the wedge or shim should

be at least four times the diameter of the anchor

bolt. It is acceptable to place additional shims

between the existing anchor bolts.

Use an anchor bolt for each anchor bolt hole

provided, and plain, flat Type-W washers at each

anchor bolt.

CAUTION: Equipment Damage

Use an anchor bolt and plain, flat Type-W washer

at each anchor bolt hole. Otherwise, shifting of the

pump unit may occur.

Failure to follow these instructions could result in

serious property damage and/or moderate

personal injury.

It is very important that the pump base be set level

to avoid any mechanical difficulties with the motor

or pump. This pump was properly aligned (if

furnished with a motor) at the factory. However,

since all pump bases are flexible, they may spring

and twist during shipment. Do not pipe the pump

until it is realigned. After piping is completed and

after the pump is installed and bolted down, align it

again. It may be necessary to re-adjust the

alignment from time to time while the unit and

foundation are new.

Optional Grouting

It is permissible to grout the base after the

pump unit has been leveled, securely bolted

to the floor, and properly aligned. A good

grade of non-shrinking grout should be used

inside the pump base.

Figure 7: Setting Base Plate

ROTATION

The Series VSX pump is available in both right-

and left-hand rotation. An arrow cast into the pump

body shows the direction of rotation.

COUPLING ALIGNMENT

All alignment should be done by moving or

shimming the motor only. Adjustments in one

direction may alter alignment in another.

Therefore, check alignment in all directions after a

correction is made. All measurements should be

taken with the pump and motor bolts tightened.

Final alignment check should be made after the

unit has attained its final operating temperature.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage.

1. Check the pump and motor shafts and

remove any paint, burrs, rust, etc. Slide

the hubs (and bushings, QD or Taper-

Lock style) on the shafts with keys.

2. When high speed rings are used for

spacer couplings, loosely install one ring

on each half element.