Bell & Gossett P5002169C Series VSCS User Manual

Page 34

32

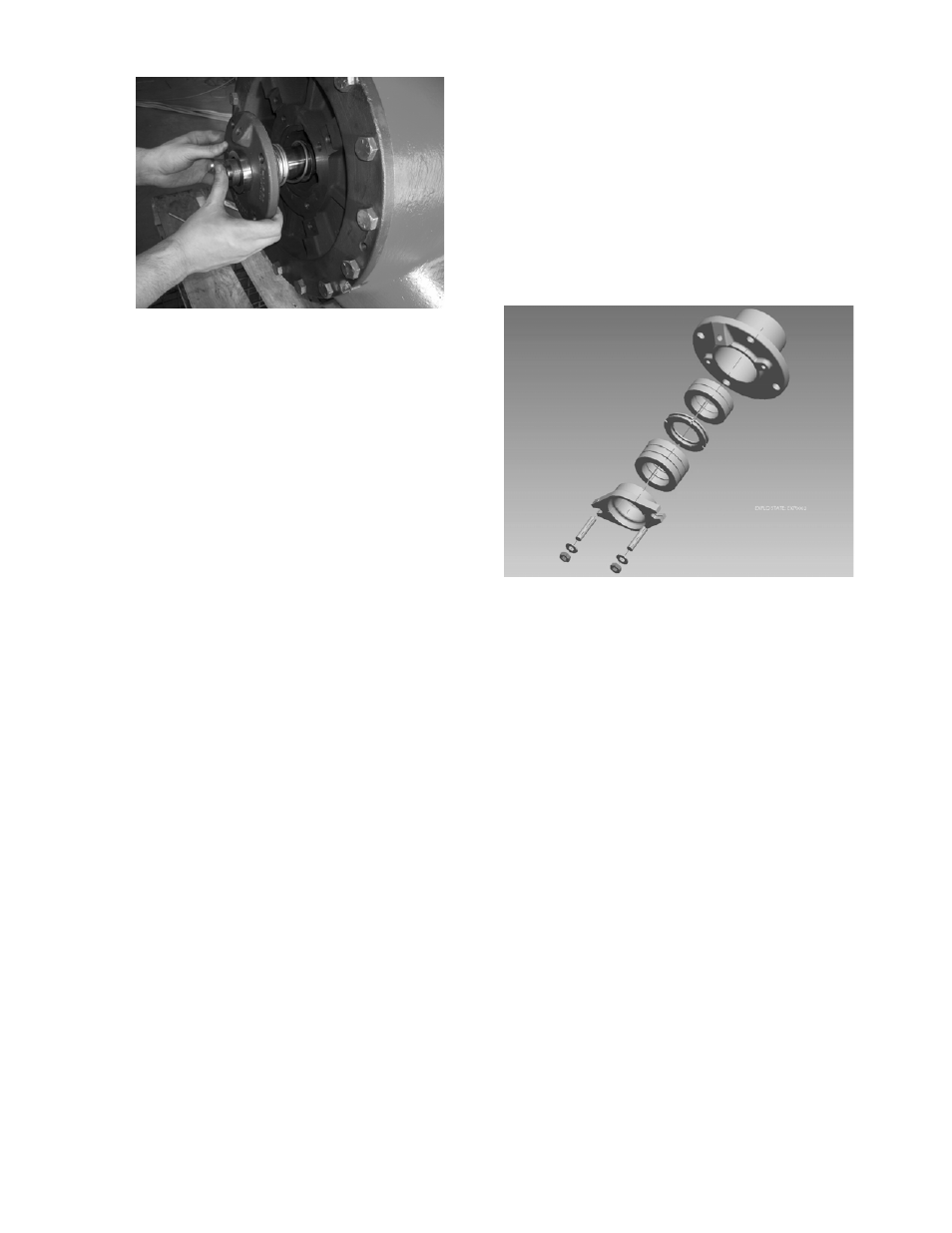

Figure 45: Installing the Gland Assembly

7. Install the four gland assembly capscrews.

8. Install the set screws in the sleeve and tighten

to 50 inch-lbs.

9. Install the slinger.

10. Repeat steps 1 through 9 to install the seal on

the other side. When finished, see the section

entitled Assembly Procedure to Install

Bearing Frames – All Pumps.

ASSEMBLY PROCEDURE TO INSTALL

STUFFING BOX AND PACKING

1. Place stuffing box, wetted end down, onto the

bench and slide the sleeve through stuffing

box bore letting it set onto bench

2. Install packing rings over the sleeve and down

into the bore so that the ends butt, leaving no

gap between the packing and stuffing box.

Press the packing to the bottom of the stuffing

box. Stagger the joints of each packing ring at

least 90°.

NOTE: On a flushed stuffing box, the lantern

ring will replace the third packing ring from

the bottom, requiring only five rings of

packing per side. (See Figure 30.) The

lantern ring must be aligned with the seal

water inlet when the packing is compressed.

On non-flushed (plugged) stuffing boxes, a

sixth ring of packing is supplied for each side

and takes the place of the lantern ring.

3. Apply anti-seize compound only to the area of

the shaft that will be under the sleeve.

4. Place the stuffing box gasket on the stuffing

box. Grease may be used to hold the gasket

in place.

5. Slide the sleeve/stuffing box subassembly

over the shaft until the sleeve bottoms out

onto the shaft locating shoulder.

6. Install the four stuffing box capscrews.

7. Install set screws in the sleeve and tighten to

50 inch-lbs.

NOTE: The last ring in each box may not be

required until after the pump has operated for a

period of time.

8. Assemble the glands, studs, washers, and

nuts square with the stuffing box and pull up

tight. (See Figure 46 of an exploded

assembly.)

Figure 46: Exploded View of Stuffing Box with

Lantern Ring

9. Repeat steps 1 through 8 for the other side.

When finished, see the section entitled

Assembly Procedure to Install Bearing

Frames – All Pumps.

NOTE: After the bearing frame has been installed,

loosen the nuts to permit the packing to expand.

Retighten until finger tight. Final adjustment of the

gland nuts must be done while the pump is

running. Allow approximately 30 minutes between

adjustments. A good adjustment should allow

approximately one drip per second.

ASSEMBLY PROCEDURE TO INSTALL

CARTRIDGE SEALS

1. Apply anti-seize compound only to the area of

the shaft that will be under the sleeve.

2. If installing an entire cartridge seal, place the

gasket onto the gland of the cartridge seal.

(See Figure 47.) Grease may be used to hold

the gasket in place. Slide the complete

assembly over the shaft until the gland fully

seats into the coverplate bore. Install and

tighten the four cartridge seal capscrews.

Push the sleeve fully home to axial stop and

tighten set screws to 130 inch-lbs.