Bell & Gossett P5002169C Series VSCS User Manual

Page 24

22

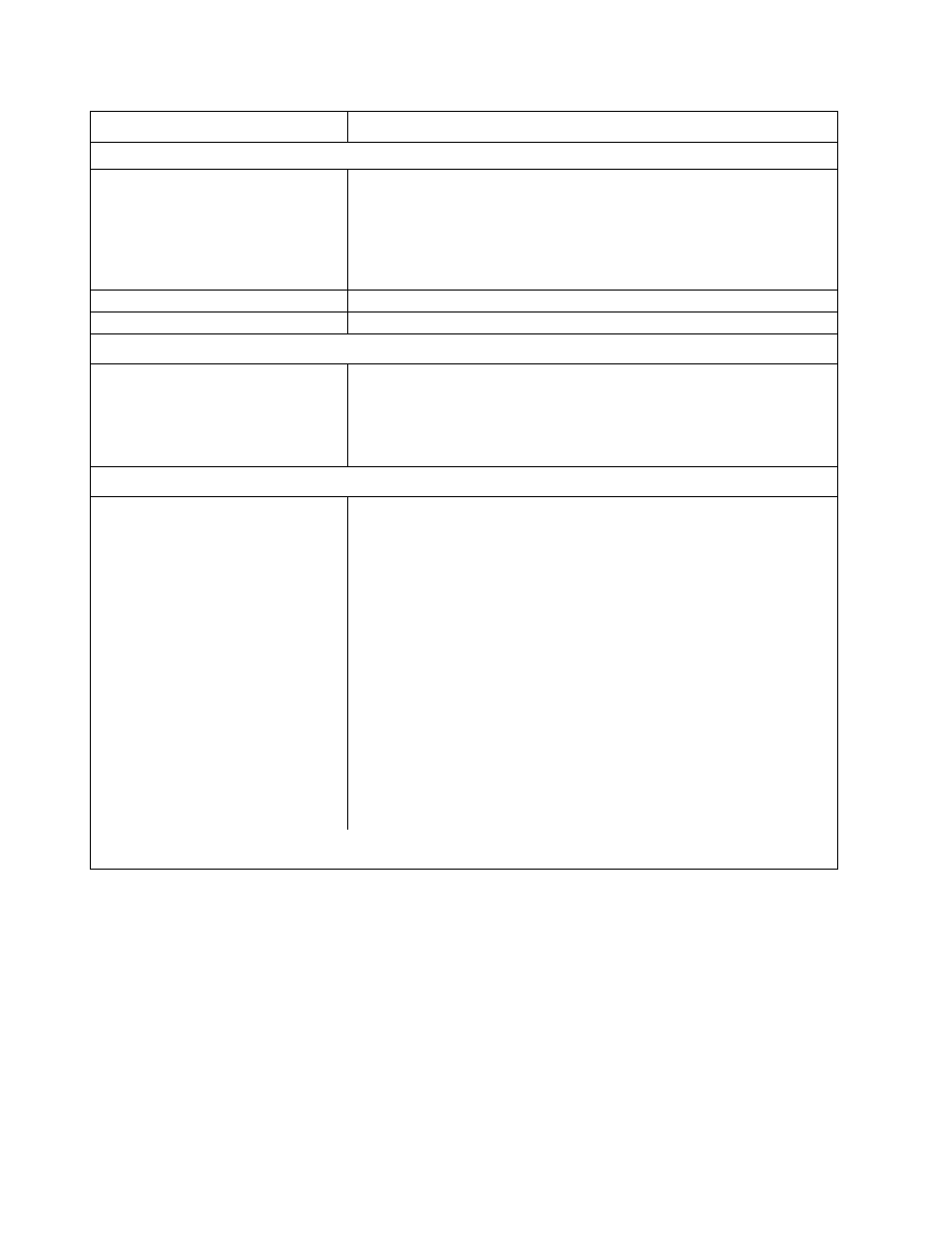

CAUSES CURES

Not Enough Pressure

20. Mechanical defects

See items 14 and 15.

21. Obstruction in liquid passages

Dismantle pump and inspect passages of impeller and casing.

Remove obstruction.

22. Air or gases in liquid

Install an air removal device or repair leaks in system piping.

23. Too small impeller diameter

(Probable cause if none above)

See item 17.

24. Speed too low

See item 5.

25. Excessive system flow

Balance system.

Pump Operates For Short Time, Then Stops

26. Incomplete priming

Free pump, piping and valves of all air. If high points in suction line

prevent this, they need correcting.

27. Suction lift too high

See item 3.

28. Air leaks in suction piping

See item 8.

29. Air or gases in liquid

See item 22.

Pump Takes Too Much Power

30. Head lower than rating;

thereby pumping too much liquid.

Machine impeller’s OD to size advised by factory.

31. Cavitation

See item 13.

32. Mechanical defects.

See items 14 and 15.

33. Liquid heavier (in either

viscosity or specific gravity) than

allowed for.

Use larger driver. Consult factory for recommended size. Test liquid

for viscosity and specific gravity.

34. Wrong direction of rotation.

See item 15.

35. Casing distorted by excessive

strains from suction or discharge

piping.

Check alignment. Examine pump for friction between impeller and

casing. Replace damaged parts.

36. Shaft bent due to damage –

through shipment, operation, or

overhaul.

Check deflection of rotor by turning on bearing journals. Total

indicator run-out should not exceed 0.002” on shaft and 0.004” on

impeller eye outer diameter.

37. Mechanical failure of critical

pump parts.

Check bearings and impeller for damage. Any irregularity in these

parts will cause a drag on shaft.

38. Misalignment.

Realign pump and driver.

39. Speed may be too high

Check frequency setting on the drive if equipped. Verify that the

driver speed matches the pump nameplate speed.