Bell & Gossett P5002169C Series VSCS User Manual

Page 15

13

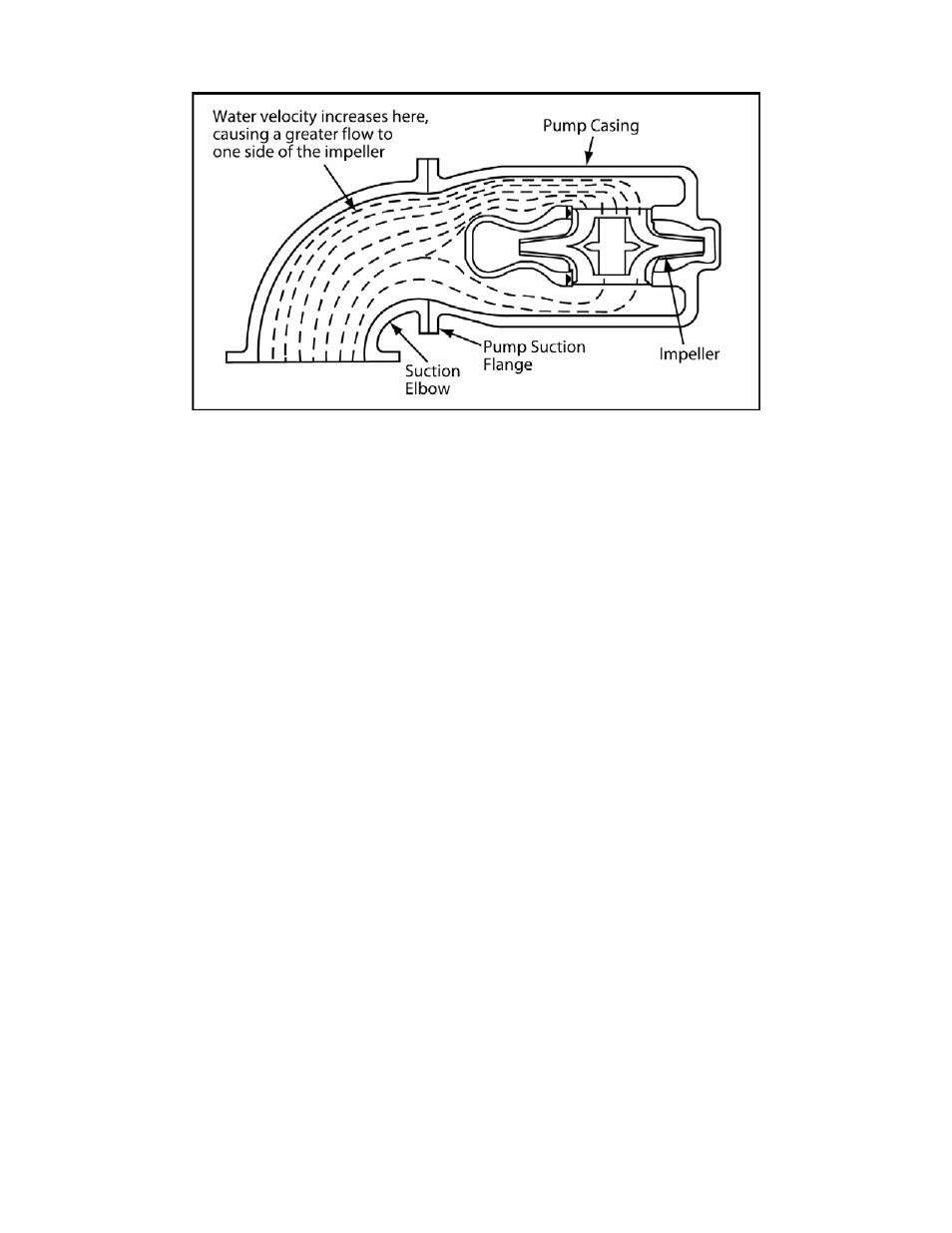

Figure 15: Unbalanced Loading of a Double Suction Impeller

Due to Uneven Flow Around an Elbow Adjacent to the Pump

When operating on a suction lift, the suction

pipe should slope upward to the pump

nozzle. A horizontal suction line must have a

gradual rise to the pump. Any high point in

the pipe can become filled with air and thus

prevent proper operation of the pump.

To facilitate cleaning the pump’s liquid

passage without dismantling the pump, a

short section of pipe (Dutchman or spool

piece), designed so that it can be readily

dropped out of the line, can be installed

adjacent to the suction flange. With this

arrangement, any matter clogging the

impeller is accessible by removing the spool

piece (or pipe section).

Valves in Suction Piping

When installing valves in the suction piping,

observe the following precautions:

Suction piping valves should be placed right

before the run of recommended straight pipe.

If the pump is operating under static suction

lift conditions, a foot valve may be installed in

the suction line to avoid the necessity of

priming each time the pump is started. This

valve should be of the flapper type, rather

than the multiple spring type, sized to avoid

excessive friction in the suction line. The foot

valve and pipe should be sized to maximize

NPSHa to the pump by minimizing suction

line losses.

Check valves are placed in the discharge

piping in normal applications. Before using a

check valve in the suction piping, consider

the added pressure drop to the pump,

potential water hammer, and the chance of

allowing the entire pump volute to be

exposed to the discharge pressure.

When foot valves are used, or where there

are other possibilities of “water hammer,”

close the discharge valve slowly before

shutting down the pump.

The pump must never be throttled by the use

of a valve on the suction side of the pump.

Suction valves should be used only to isolate

the pump for maintenance purposes, and

should always be installed in positions to

avoid air pockets.

Discharge Piping

The maximum velocity in the discharge piping

should not exceed 15 feet per second. If a

check valve is present in the outlet piping,

this value shall be reduced. System losses,

life-cycle costs, and process considerations

will usually drive the size of discharge piping

and fittings. Some high energy pumps are

sensitive to flow disturbing devices mounted

close to the pump outlet. Consult Bell &

Gossett when in doubt of the minimum

required straight pipe length.