Bell & Gossett P5002169C Series VSCS User Manual

Page 10

8

3. Hold one half element on the hubs to

determine the appropriate hub spacing. If

using spacer elements with high speed

rings, hold both half elements on the hubs

to make sure the hubs do not interfere

with the rings. The hubs may be installed

with the hub extension facing in or out.

Make sure the shaft extends into the hubs

at least .8 times the diameter of the shaft.

4. Lightly fasten the hubs to the shafts to

prevent them from moving during

alignment.

5. The hubs should be aligned to at least the

values shown in Figure 10 for allowable

misalignments. Alignment may be done

with lasers, dial indicators, or with a

straight edge and calipers.

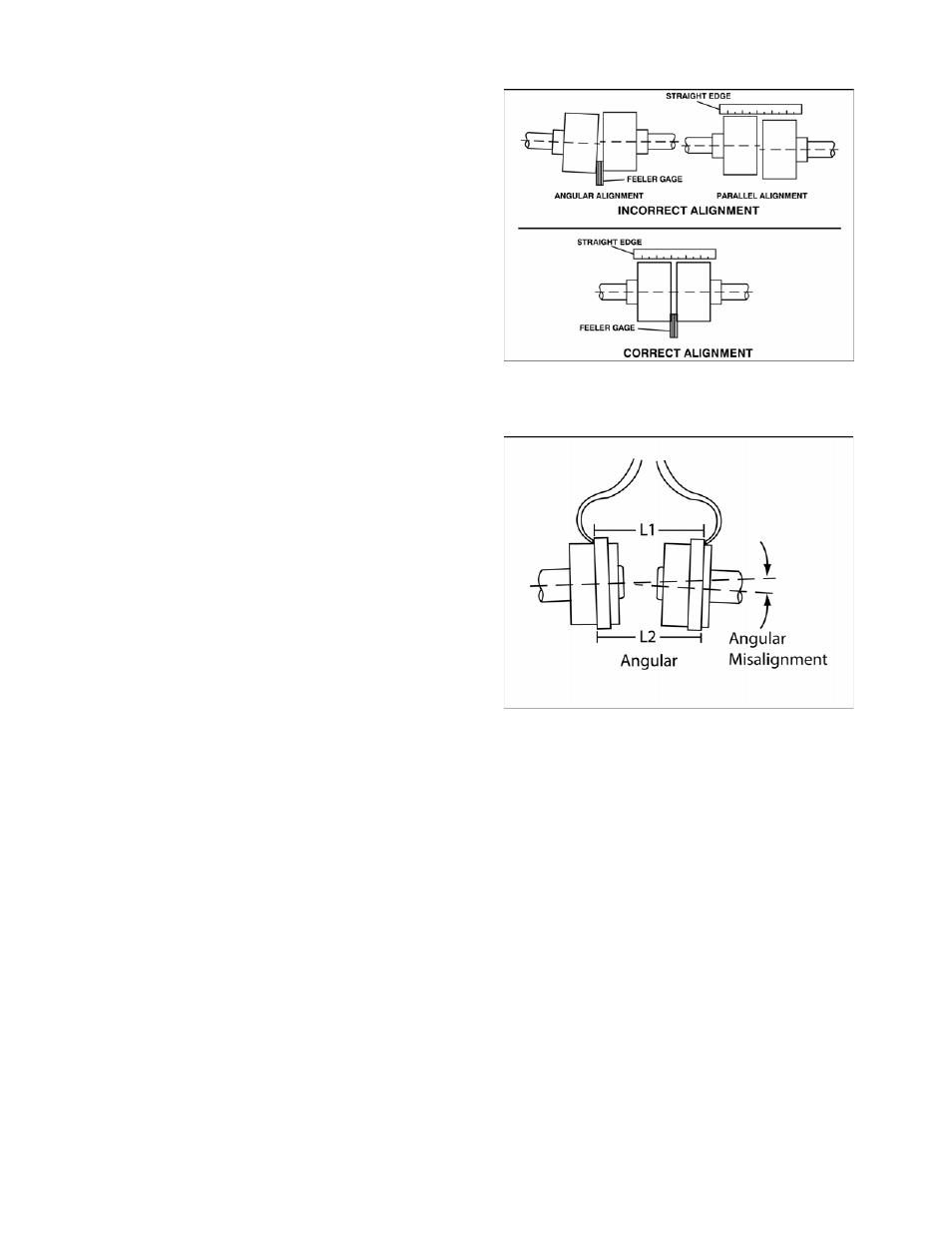

To align using straight edge and calipers

Angular misalignment may be checked by

using a caliper to gauge the distance

between the two hubs at various points

around the circumference. Do not rotate the

shafts. Reposition the equipment until the

difference between the minimum and

maximum distance values is within the

permissible value.

Angular misalignment may also be checked

by inserting feeler gauges between the

coupling faces at various points around the

circumference. Do not rotate the shafts.

Reposition the equipment until the difference

between the minimum and maximum

distance values is within the permissible

value.

Parallel alignment may be checked by placing

a straight edge across the two hubs and

measuring the maximum offset at various

points around the periphery of the hubs. Do

not rotate the shafts. Reposition equipment

until the offset is within the permissible value.

Figure 8: Checking Alignment with

Straight Edge

Figure 9: Checking Alignment with Calipers