Bell & Gossett P5002169C Series VSCS User Manual

Page 28

26

GENERAL DISASSEMBLY PROCEDURES

SHUTDOWN

The following steps will address most normal

shutdowns of the pump, such as maintenance.

Make any further adjustments of process piping,

valves, etc., as required.

1. Shut down the pump driver. (Consult

manufacturer’s instructions for special

operations.)

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in

serious personal injury or death, or property

damage

.

2. Close the suction and discharge valves.

3. For pumps equipped with external flush, close

the flush line valves. However, to prevent

contaminating the packing, leave these lines

open, unless the pump is completely drained.

4. Open the drain valves and casing vents as

required.

CAUTION: Extreme Temperature Hazard

Allow pump temperatures to reach acceptable

levels before proceeding. Open the drain valve.

Do not proceed until liquid stops coming out of the

drain valve. If liquid does not stop flowing from the

drain valve, isolation valves are not sealing and

should be repaired before proceeding. After liquid

stops flowing from drain valve, leave the valve

open and continue. Remove the drain plug located

on the bottom of the pump housing. Do not

reinstall the plug or close the drain valve until

reassembly is completed.

Failure to follow these instructions could result in

moderate personal injury or property damage.

DISASSEMBLY PROCEDURE TO REMOVE

BEARING FRAMES – ALL PUMPS

1. Remove the coupling guard. See the Guards

section.

2. Remove the capscrews that secure the

coupling element to the hubs. Remove the

coupling element. Depending on the type of

coupling, proceed to step a or step b.

a. For

non-spacer

coupling

assemblies: move the driver to

allow sufficient access for

maintenance and remove the

coupling hub on the pump.

b. For spacer coupling assemblies:

remove the coupling hub on the

pump.

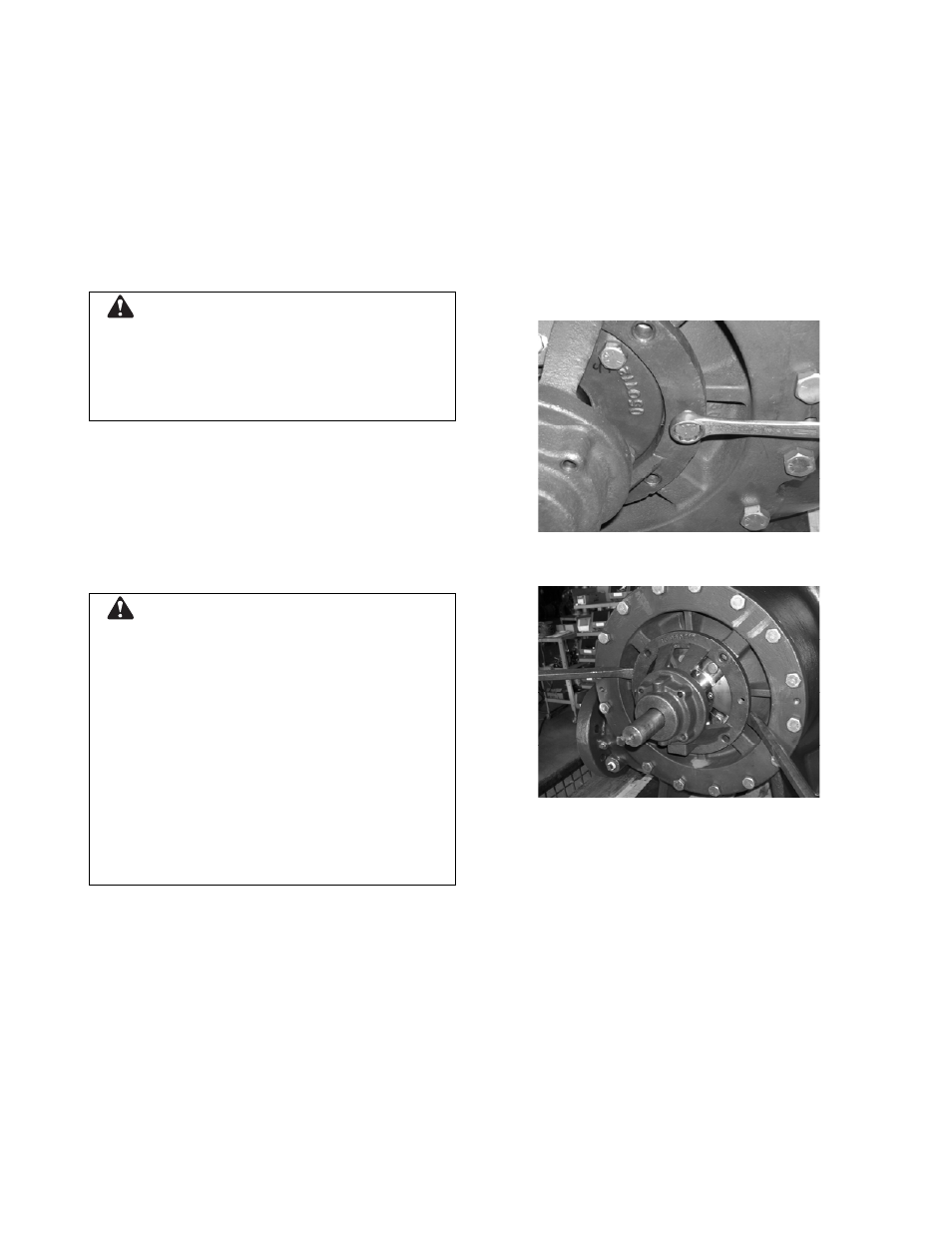

3. Remove the four capscrews from the bearing

cap.

4. Remove the four bearing bracket capscrews.

5. Remove the bearing bracket using jacking

screws. (See Figure 23.) Pry bars may also be

used. (See Figure 24.)

Figure 23:

Removing the Outboard Bearing

Bracket Using Jacking Screws

Figure 24:

Removing the Inboard Bearing Bracket

Using Pry Bars

6. Bend back the lockwasher tab and remove the

locknut and lockwasher.

7. Remove the bearing with pullers. (See Figure

25.) A universal fixture kit (part number

AC2394) may also be used. (See Figure 26.)

The universal fixture kit should not be used on

pumps with 2” frames as the bearing backup

ring may damage the bearing cap’s lip seal.

(See Figure 27 for a listing of pump sizes with

2” frames.)