Bell & Gossett P5002169C Series VSCS User Manual

Page 16

14

Pressure Gauges

Properly sized pressure gauges should be

installed in both the suction and discharge

nozzles in the gauge taps. The gauges will

enable the operator to easily observe the

operation of the pump, and also determine if

the pump is operating in conformance with

the performance curve. If cavitation, vapor

binding, or other unstable operation should

occur, widely fluctuating discharge pressure

will be noted.

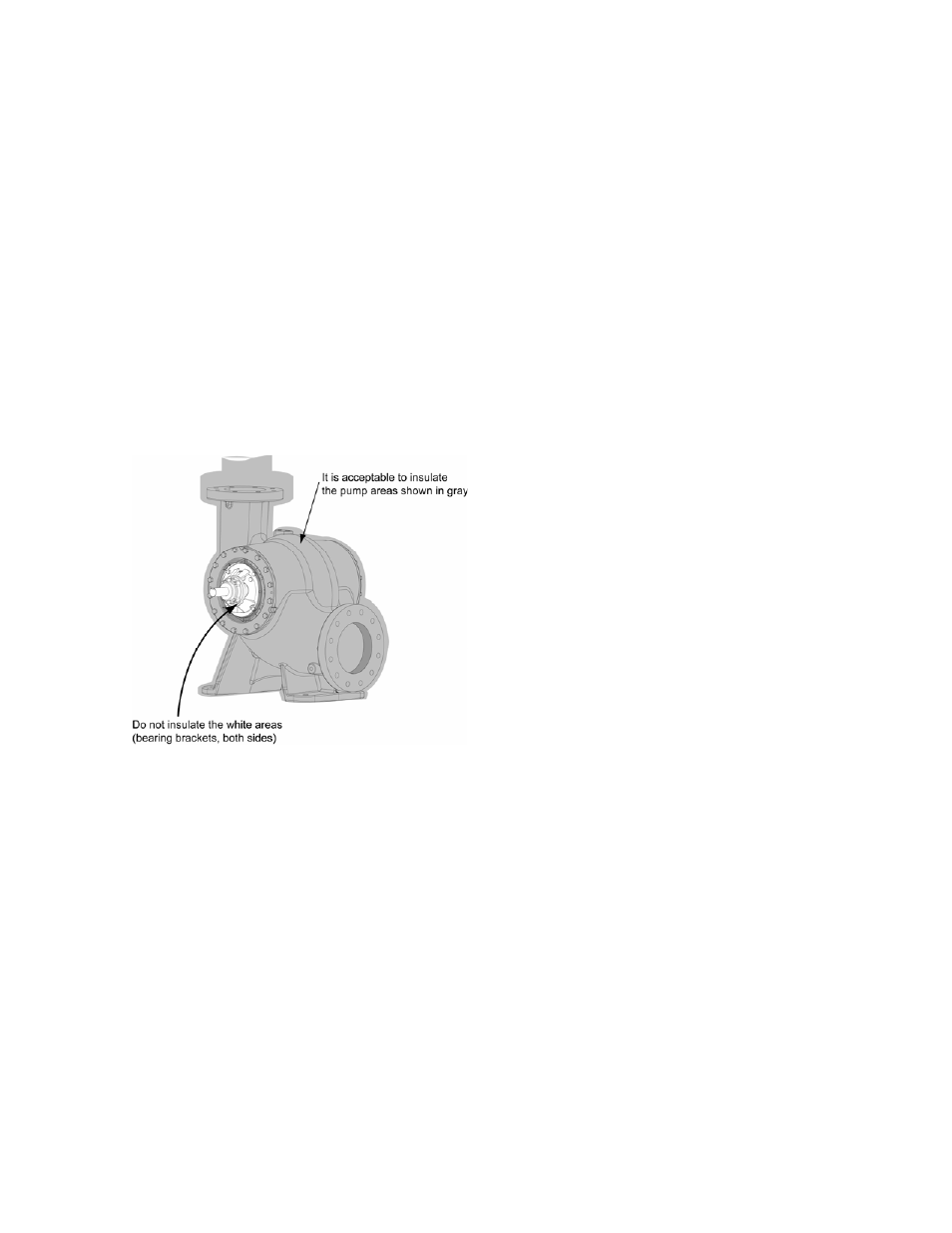

Pump Insulation

On applications where pumps are insulated,

the pump bearing brackets should not be

insulated since this would tend to trap heat

inside the housing. This could lead to

increased bearing temperatures and

premature bearing failures.

Figure 16: Pump Insulation

PUMP SEALING

Mechanical Seals

Mechanical seals are preferred over packing

on some applications because of better

sealing qualities and longer serviceability.

When a seal is properly installed, it will last

longer than packing on similar applications.

The change from packing to an alternate

arrangement may be made in the field by

competent service personnel. Conversion

parts may be ordered from your local Bell &

Gossett representative.

Packing

Contaminants in the pumped liquid must not

enter the stuffing box. These contaminants

may cause severe abrasion or corrosion of

the shaft sleeve, and rapid packing

deterioration; they can even plug the stuffing

box flushing and lubrication system. The

stuffing box must be supplied at all times with

a source of clean, clear liquid to flush and

lubricate the packing.

If the pump system pressure conditions vary

during the day, packing adjustment becomes

difficult. Consideration should be given to

using a mechanical seal.

Standard pumps are normally packed before

shipment. If the pump is installed within 60

days after shipment, the packing will be in

good condition with a sufficient supply of

lubrication. If the pump is stored for a longer

period, it may be necessary to repack the

stuffing box. In all cases, however, inspect

the packing before the pump is started.

NOTE: Packing adjustment is covered in the

section entitled Maintenance.

On some applications, it is possible to use internal

liquid lubrication (pumped liquid) to lubricate

packing. Only when all of the following conditions

prevail, can this be done:

1. Liquid is clean, free from sediment and

chemical precipitation and is compatible

with seal materials.

2. Temperature is above 32°F and below

160°F.

3. Suction pressure is below 75 psig.

4. Lubrication (pumped liquid) has lubricating

qualities.

5. Liquid is non-toxic and non-volatile.

When the liquid being pumped contains solids or

is otherwise not compatible with packing materials,

an outside supply of flush liquid should be

furnished. In general, external-flush liquid (from an

outside source) is required when any of the above

conditions cannot be met.

The standard stuffing box consists of rings of

packing (See the Assembly and Disassembly

Procedures section for the number of rings), a

lantern ring, and a gland. A shaft sleeve that

extends through the box and under the gland is

provided to protect the shaft.

A tapped hole is supplied in the stuffing box

directly over the lantern ring to introduce a clean,

cooling medium. The stuffing box must, at all