Seal-chamber cover inspection and replacement, Replace the seal-chamber cover bushing – Goulds Pumps 3700 - IOM User Manual

Page 80

Maintenance

1. Check for distortion at the set screw areas.

2. Check the shaft runout and all mating surfaces of the shaft and impeller hub for

perpendicularity.

3. True up all damaged surfaces.

4. Recheck the impeller wear-ring runout.

Seal-chamber cover inspection and replacement

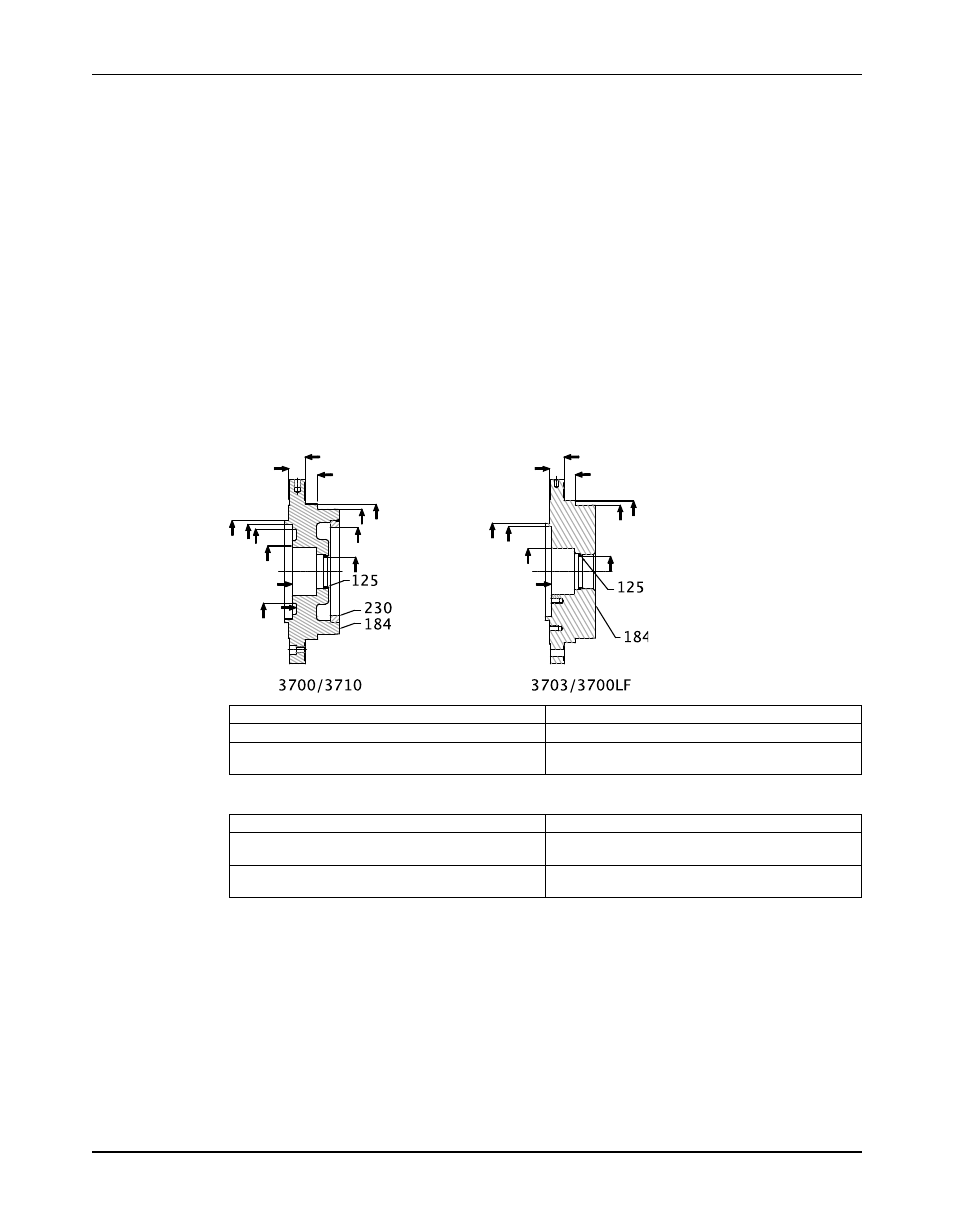

Two seal-chamber cover versions

The seal-chamber cover is available in two versions:

• Standard

• Optional

The optional version has a cooling chamber and water jacket cover and is used when elevated

pumped-fluid temperatures are present.

Seal-chamber cover areas to inspect

• Ensure all gasket/O-ring sealing surfaces are clean and have no damage that would

prevent sealing.

• Ensure that all cooling (where applicable), flush, and drain passages are clear.

125

Seal-chamber throat bushing

184

Seal-chamber cover

230

Seal-chamber cover wear ring (not present on

3703/3700LF)

Seal-chamber cover replacement

Seal-chamber cover part

When to replace

Seal-chamber cover surfaces

When worn, damaged, or corroded more than 0.126

in. (3.2 mm) deep

Inside diameter of seal-chamber cover bushing

When the diametral clearance between the bushing

and the impeller hub exceeds 0.047 in. (1.20 mm)

Replace the seal-chamber cover bushing

The seal-chamber cover bushing is held in place by a press fit and locked by three set screws.

1. Remove the bushing:

a) Remove the set screws.

78

Model 3700, API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Installation, Operation, and Maintenance

Manual