Goulds Pumps 3700 - IOM User Manual

Page 33

Installation

Liquid source below the pump

Check

Explanation/comment

Checked

Make sure that the suction piping

This helps to prevent the occur-

is free from air pockets.

rence of air and cavitation in the

pump inlet.

Check that the suction piping

—

slopes upwards from the liquid

source to the pump inlet.

If the pump is not self-priming,

Use a foot valve with a diameter

check that a device for priming the that is at least equivalent to the

pump is installed.

diameter of the suction piping.

Liquid source above the pump

Check

Explanation/comment

Checked

Check that an isolation valve is

This permits you to close the line

installed in the suction piping at a

during pump inspection and main-

distance of at least two times the

tenance.

pipe diameter from the suction

Do not use the isolation valve to

inlet.

throttle the pump. Throttling can

cause these problems:

• Loss of priming

• Excessive temperatures

• Damage to the pump

• Voiding the warranty

Make sure that the suction piping

This helps to prevent the occur-

is free from air pockets.

rence of air and cavitation in the

pump inlet.

Check that the piping is level or

—

slopes downward from the liquid

source.

Make sure that no part of the

—

suction piping extends below the

suction flange of the pump.

Make sure that the suction piping

This prevents air from entering the

is adequately submerged below

pump through a suction vortex.

the surface of the liquid source.

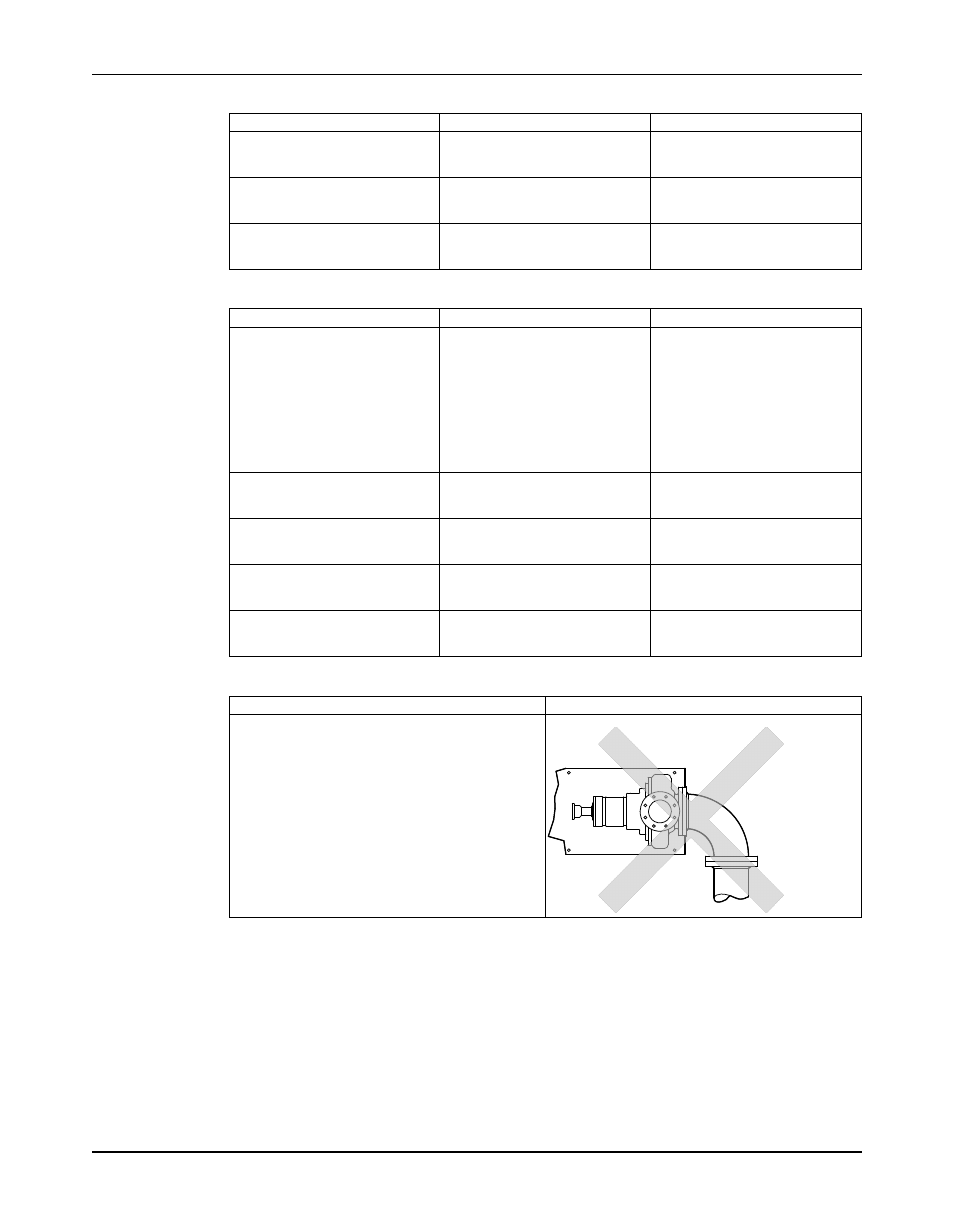

Example: Elbow close to the pump suction inlet

Correct

Incorrect

The correct distance between the inlet flange of the

pump and the closest elbow must be at least five

pipe diameters.

Model 3700, API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Installation, Operation, and Maintenance

31

Manual