Lubricating-oil requirements, Acceptable oil for lubricating bearings, Lubricate the bearings with oil – Goulds Pumps 3700 - IOM User Manual

Page 49

Commissioning, Startup, Operation, and Shutdown

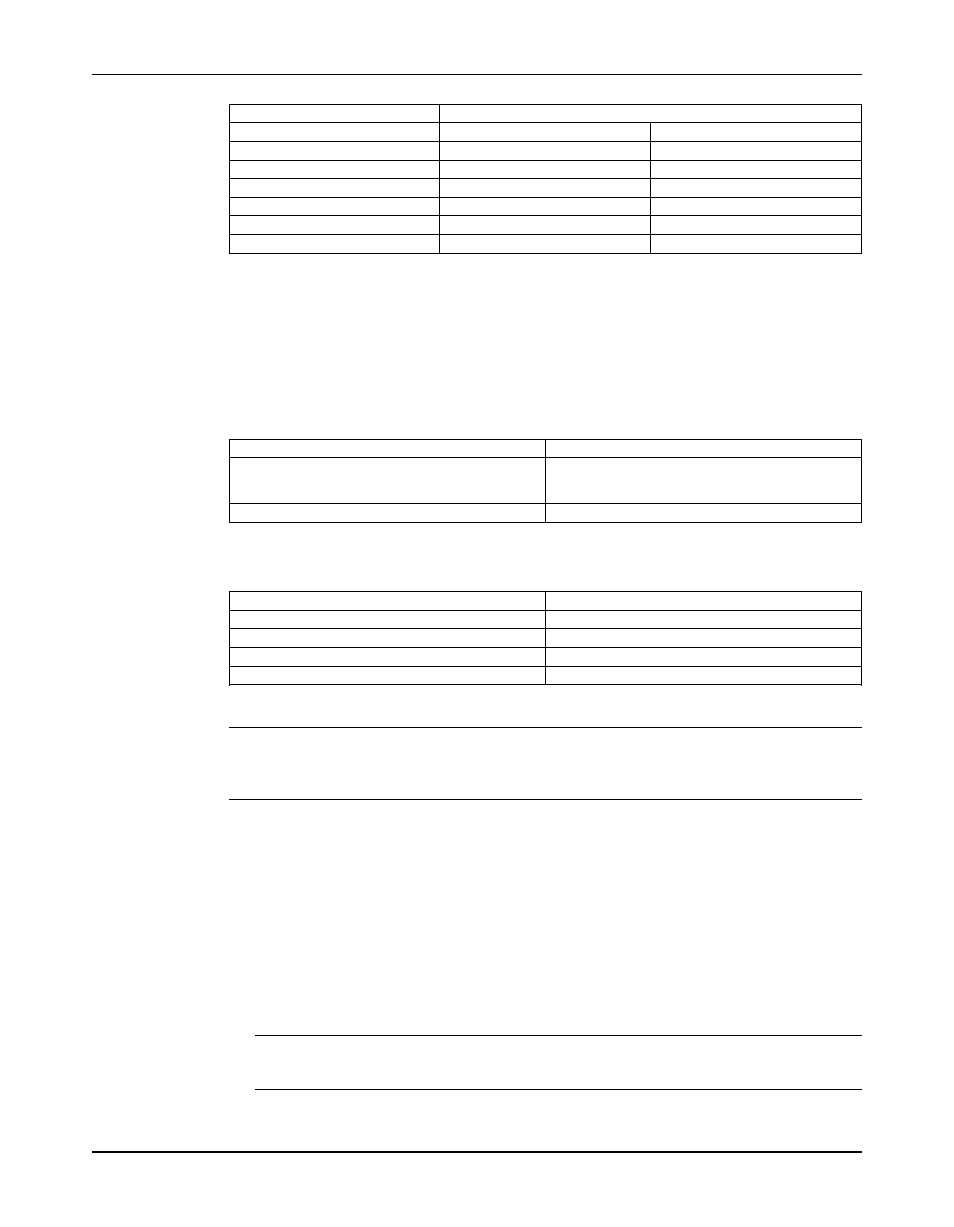

All frames in this table use a Watchdog Oiler, which has a capacity of 4 oz. (118 ml).

Frame

Frame oil volume

ounces

milliliters

SA

20

600

SX

38

1115

MA

32

950

MX, LA

47

1385

LX, XLA

72

2120

XLX, XXL

89

2625

Lubricating-oil requirements

Oil quality requirements

Use a high-quality turbine oil with rust and oxidation inhibitors with rated viscosity shown below

at 100°F (38°C).

Oil requirements based on temperature

For the majority of operating conditions, bearing temperatures run between 120°F (49°C) and 180°F

(82°C), and you can use an oil of ISO viscosity grade 68 at 100°F (38°C). If temperatures exceed 180°F

(82°C), refer to the table for temperature requirements.

Temperature

Oil requirement

Bearing temperatures exceed 180°F (82°C)

Use ISO viscosity grade 100. Bearing temperatures

are generally about 20°F (11°C) higher than bear-

ing-housing outer surface temperatures.

Pumped-fluid temperatures are extreme

Refer to the factory or a lubrication expert.

Acceptable oil for lubricating bearings

Acceptable lubricants

Brand

Lubricant type

Exxon

Teresstic EP 68

Mobil

DTE Heavy Medium

Sunoco

Sunvis 968

Royal Purple

SYNFILM ISO VG 68 Synthetic Lube

Lubricate the bearings with oil

NOTICE:

Do not expose an idle pump to freezing conditions. Drain all liquid that is inside the pump and

the cooling coils. Failure to do so can cause liquid to freeze and damage the pump.

Ring oil-lubricated pumps are supplied with an oiler that maintains a constant oil level in the

bearing housing.

1. Fill the oil reservoir in the bearing frame:

a) Fill the bearing chamber through the main body of the Watchdog until it reaches the

optimum fluid level visible in the bullseye sight.

b) Fill the watchdog reservoir using a funnel.

c) Verify o-ring is on the Watchdog oiler spout.

d) Place your thumb over the reservoir spout. Invert and insert the spout into the internal

threaded boss on the main body.

e) Tighten reservoir. Do not over-tighten.

f)

Verify that proper oil level is maintained per the following diagram.

NOTICE:

Do not fill the oil reservoir of the bearing frame through the plug at the top.

Model 3700, API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Installation, Operation, and Maintenance

47

Manual