Discharge piping checklist – Goulds Pumps 3700 - IOM User Manual

Page 34

Installation

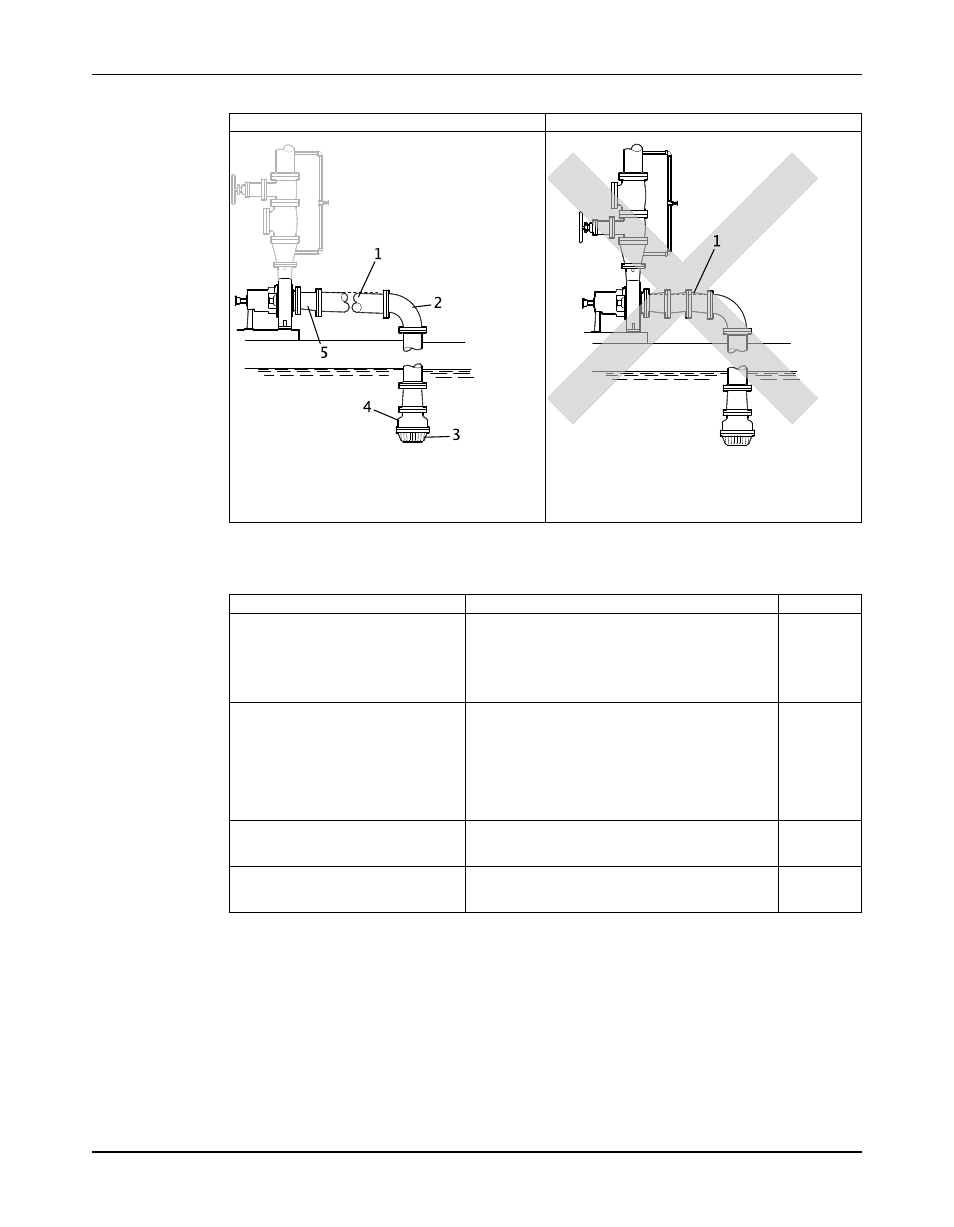

Example: Suction piping equipment

Correct

Incorrect

1.

Suction pipe sloping upwards from liquid source 1.

Air pocket, because the eccentric reducer is not

2.

Long-radius elbow

used and because the suction piping does not

3.

Strainer

slope gradually upward from the liquid source

4.

Foot valve

5.

Eccentric reducer with a level top

Discharge piping checklist

Checklist

Check

Explanation/comment

Checked

Check that an isolation valve is in-

The isolation valve is required for:

stalled in the discharge line.

• Priming

• Regulation of flow

• Inspection and maintenance of the pump

See Example: Discharge piping equipment for

illustrations.

Check that a check valve is installed in The location between the isolation valve and the

the discharge line, between the isola-

pump allows inspection of the check valve.

tion valve and the pump discharge

The check valve prevents damage to the pump and

outlet.

seal due to the back flow through the pump, when

the drive unit is shut off. It is also used to restrain

the liquid flow.

See Example: Discharge piping equipment for

illustrations.

If increasers are used, check that they See Example: Discharge piping equipment for

are installed between the pump and

illustrations.

the check valve.

If quick-closing valves are installed in

This protects the pump from surges and water

the system, check that cushioning de- hammer.

vices are used.

32

Model 3700, API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Installation, Operation, and Maintenance

Manual