Goulds Pumps 3700 - IOM User Manual

Page 79

Maintenance

NOTICE:

• All replacement impeller wear rings, except those that are hard-faced, are supplied

0.020 in. to 0.030 in. (0.51 mm to 0.75 mm) oversize.

• Do not machine all wear rings. Spare hard-faced impeller wear rings are supplied to

pre-established clearances when both impeller and casing wear rings are renewed.

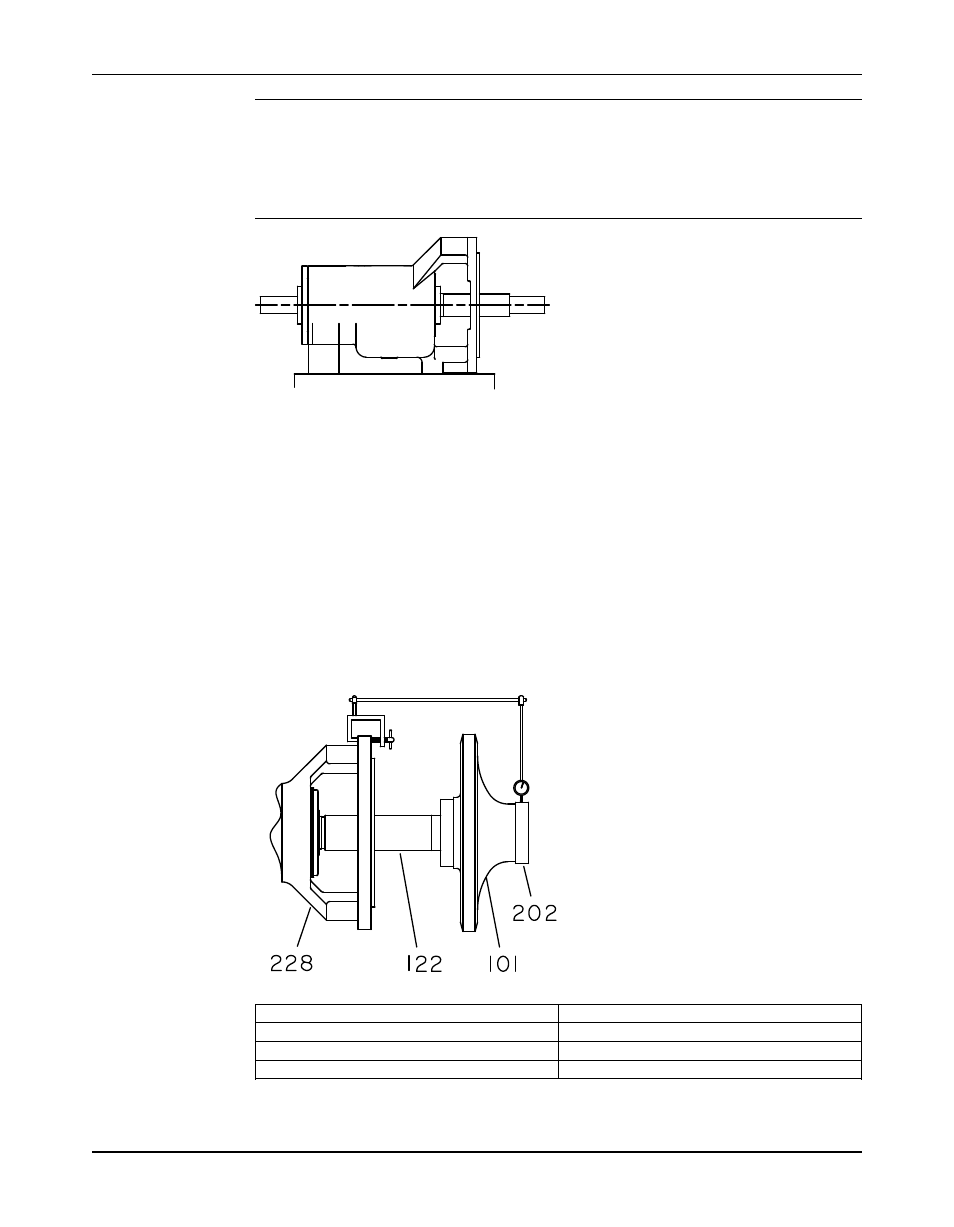

10. Install the impeller:

a) Install the impeller key on the shaft of the assembled bearing frame from which the

seal-chamber cover has been removed, and on which the runouts are within the

established specifications. The key should be at the top (12 o’clock) position for the

impeller installation.

b) Install the impeller on the shaft.

c) Install the impeller washer.

d) Secure the impeller firmly with an impeller screw or impeller nut.

The impeller screw has left-hand threads.

11. Check the impeller wear-ring runout:

a) Mount the dial indicator.

b) Rotate the shaft so that the indicator rides along the casing-side impeller wear-ring

surface for 360°.

c) Repeat steps a and b for the wear ring on the seal-chamber cover side.

101

Impeller

122

Shaft

202

Casing-side impeller wear-ring

228

Seal-chamber cover side wear ring

If the impeller wear ring runout is in excess of 0.005 in. (0.13 mm):

Model 3700, API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Installation, Operation, and Maintenance

77

Manual