Final piping checklist – Goulds Pumps 3700 - IOM User Manual

Page 36

Installation

When to install

You may need to install auxiliary piping for bearing cooling, seal-chamber cover cooling,

mechanical seal flush, or other special features supplied with the pump. Consult the pump data

sheet for specific auxiliary piping recommendations.

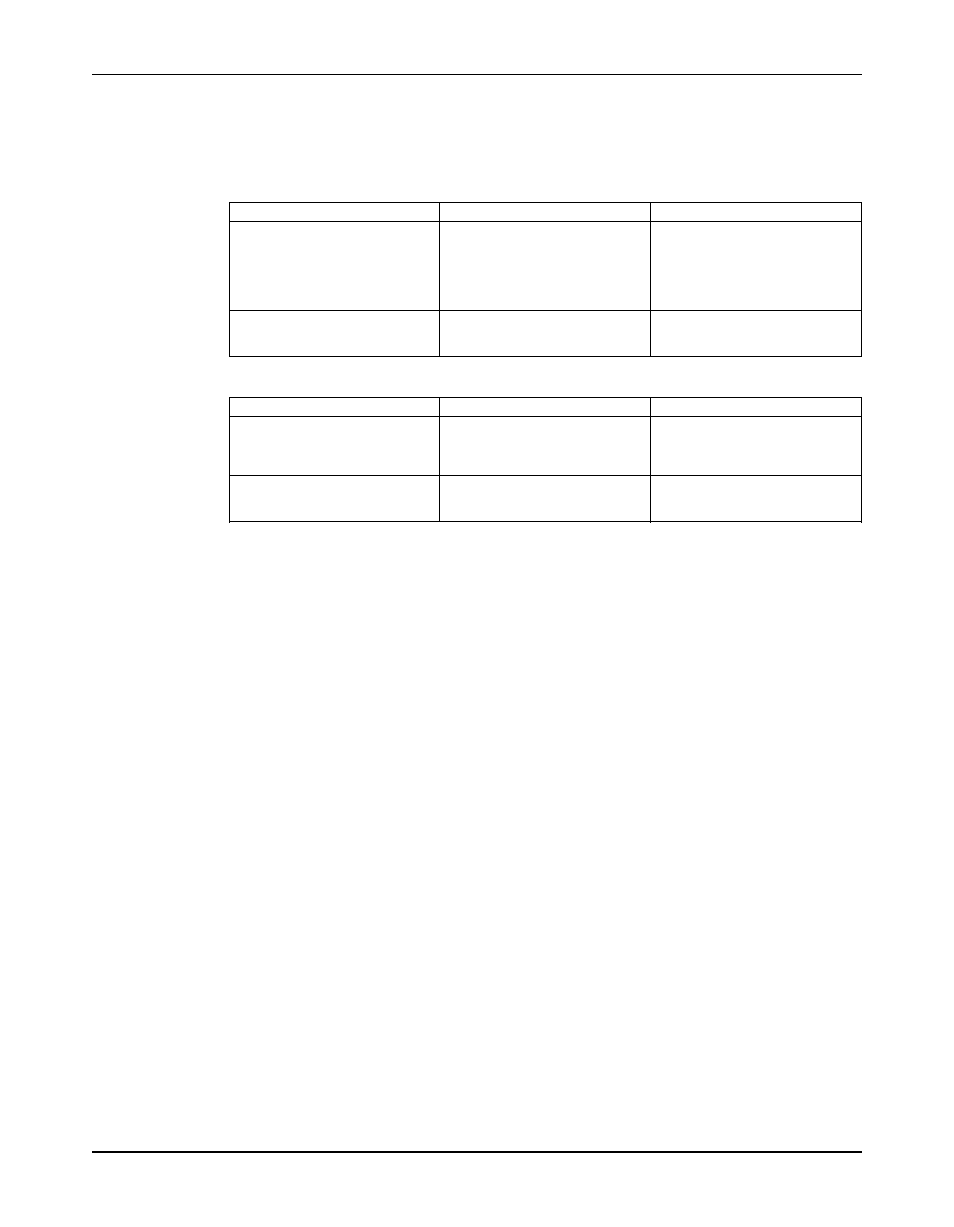

Checklist

Check

Explanation/comment

Checked

Check that the minimum flow for

Make sure that these guidelines

each component is 1 gpm (4 lpm). are followed.

If the bearing and seal chamber

cover cooling are provided, then

the auxiliary piping must flow at 2

gpm (8 lpm).

Check that the cooling water pres- Make sure that these guidelines

sure does not exceed 100 psig

are followed.

(7.0 kg/cm

2

).

Final piping checklist

Check

Explanation/comment

Checked

Check that the shaft rotates

Rotate the shaft by hand. Make

smoothly.

sure there is no rubbing that can

lead to excess heat generation or

sparks.

Re-check the alignment to make

If pipe strain exists, then correct

sure that pipe strain has not

the piping.

caused any misalignment.

34

Model 3700, API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Installation, Operation, and Maintenance

Manual