Protection of configuration, Rstr, Ktyp – NOVUS Controller N1100 User Manual

Page 8: Prot

N1100 Controller

NOVUS AUTOMATION

8/11

rsL(

Remote SP Low

Calibration

See section: MAINTENANCE / Input Calibration.

Enter the value corresponding to the low scale

signal applied to the remote SP input.

rsk(

Remote SP

High Calibration

See section: MAINTENANCE / Input Calibration.

Enter the value corresponding to the full scale

signal applied to the remote SP input.

0vL(

Output Low

Calibration

See section MAINTENANCE / Analog output

Calibration.

Enter the analog value as measured at the analog

output.

0vk(

Output High

Calibration

See section MAINTENANCE / Analog output

Calibration.

Enter the analog value as measured at the analog

output.

rstr

Restore

Restores the factory calibration for all input, analog

output and remote SP, disregarding modifications

carried out by the user.

(j

Cold Junction

Adjusts the of cold junction temperature value.

ktyp

Hardware Type

Parameter that informs the controller about the

hardware optionals installed. It should not be altered

by the user, except when an accessory is introduced

or removed.

0 – Basic model, without optional I/Os, with or

without RS485.

1 – 3R (485)

2 – DIO (3R)

Pas.(

Password

Change

Allows defining a new access password, always

different from zero.

Prot

Protection

Sets up the Level of Protection. See Table 6.

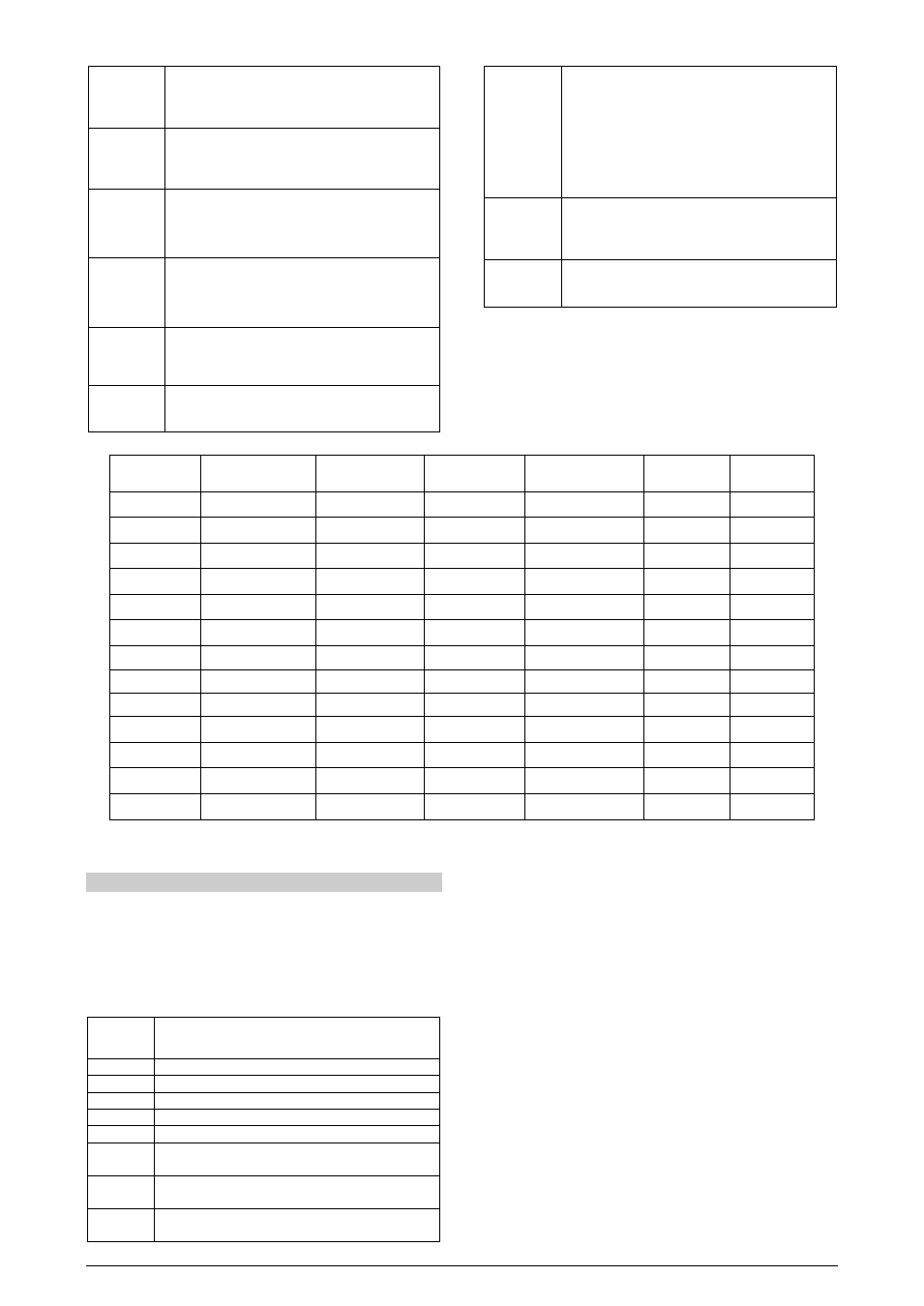

OPERATION

CYCLE

TUNING CYCLE

PROGRAMS CYCLE

ALARM CYCLE

SCALE CYCLE

I/OS CYCLE

CALIBRATION

CYCLE

PV / SP

atvn

Tbas

fva1

- fva4

type

io1

pass

Avto

pb

pr n

bla1

- bla4

dppo

Io2

Inl(

PV / MV

ir

Ptol

kya1

- kya4

vnit

Io3

Ink(

Pr n

dt

psp0

–psp7

a1t1

Offs

Io4

Rsl(

Rvn

(t

pt1

– pt7

a1t2

Spll

Io5

Rsk(

Kyst

Pe1

– pe7

a2t1

Spkl

0vl(

a(t

Lp

a2t2

e.rsp

0vk(

bias

Rsp

rstr

ovll

Rsll

(j

ovkl

Rskl

ktyp

sfst

Bavd

Pas.(

Spa1

- spa4

Prty

prot

addr

Table6 – All the controller parameter

PROTECTION OF CONFIGURATION

The controller provides means for protecting the parameters

configurations, not allowing modifications to the parameters values,

avoiding tampering or improper manipulation.

The parameter Protection (PROt), in the Calibration level,

determines the protection strategy, limiting the access to particular

levels, as shown by the table below.

Protection

Level

Protected Cycles

1

Only the Calibration level is protected.

2

I/Os and Calibration levels.

3

Tuning, I/Os and Calibration levels.

4

Alarm, Tuning, I/Os and Calibration levels.

5

Programs, Alarm, Tuning, I/Os and Calibration levels.

6

Tuning, Programs, Alarm, Input, I/Os and Calibration

levels.

7

Operation (except SP), Tuning, Programs, Alarm,

Scale, I/Os and Calibration levels.

8

Operation (including SP), Tuning, Programs, Alarm,

Scale, I/Os and Calibration levels.

Table7 - Levels of Protection for the Configuration

Access Password

The protected levels, when accessed, request the user to provide the

Access Password for granting permission to change the

configuration of the parameters on these cycles.

The prompt PASS precedes the parameters on the protected levels.

If no password is entered, the parameters of the protected cycles can

only be visualized.

The Access Code is defined by the user in the parameter Password

Change (PAS.(), present in the Calibration level

The factory default for the password code is 1111.

Protection of the access code

The protection system built into the controller blocks for 10 minutes

the access to protected parameters after 5 consecutive frustrated

attempts of guessing the correct password.

Master Password

The Master Password is intended for allowing the user to define a

new password in the event of it being forgotten. The Master

Password doesn’t grant access to all parameters, only to the

Password Change parameter (PAS(). After defining the new

password, the protected parameters may be accessed (and

modified) using this new password.