ROTHENBERGER Modul ROSCAN 150 User Manual

Page 27

ENGLISH

25

Surface Material

Emissivity

Coefficient

Surface Material

Emissivity

Coefficient

Concrete, rough

0.94

Steel Oxidized

0.79

Concrete tiles

0.63

Steel Polished

0.07

Cotton Cloth

0.77

Stainless Steel, weathered

0.85

Copper electroplated

0.03

Stainless Steel, polished

0.075

Copper heated and covered

with thick oxide layer

0.78

Stainless Steel, type 301

0.54 - 0.63

Steel Galvanized Old

0.88

Copper Polished

0.023 - 0.052

Steel Galvanized New

0.23

Copper Nickel Alloy, polished

0.059

Tile

0.97

Glass smooth

0.92 - 0.94

Water

0.95 - 0.963

Glass, Pyrex

0.85 - 0.95

Wood Beech, planned

0.935

Granite

0.45

Wood Oak, planned

0.885

Gypsum

0.85

Wood, Pine

0.95

Ice smooth

0.966

Wrought Iron

0.94

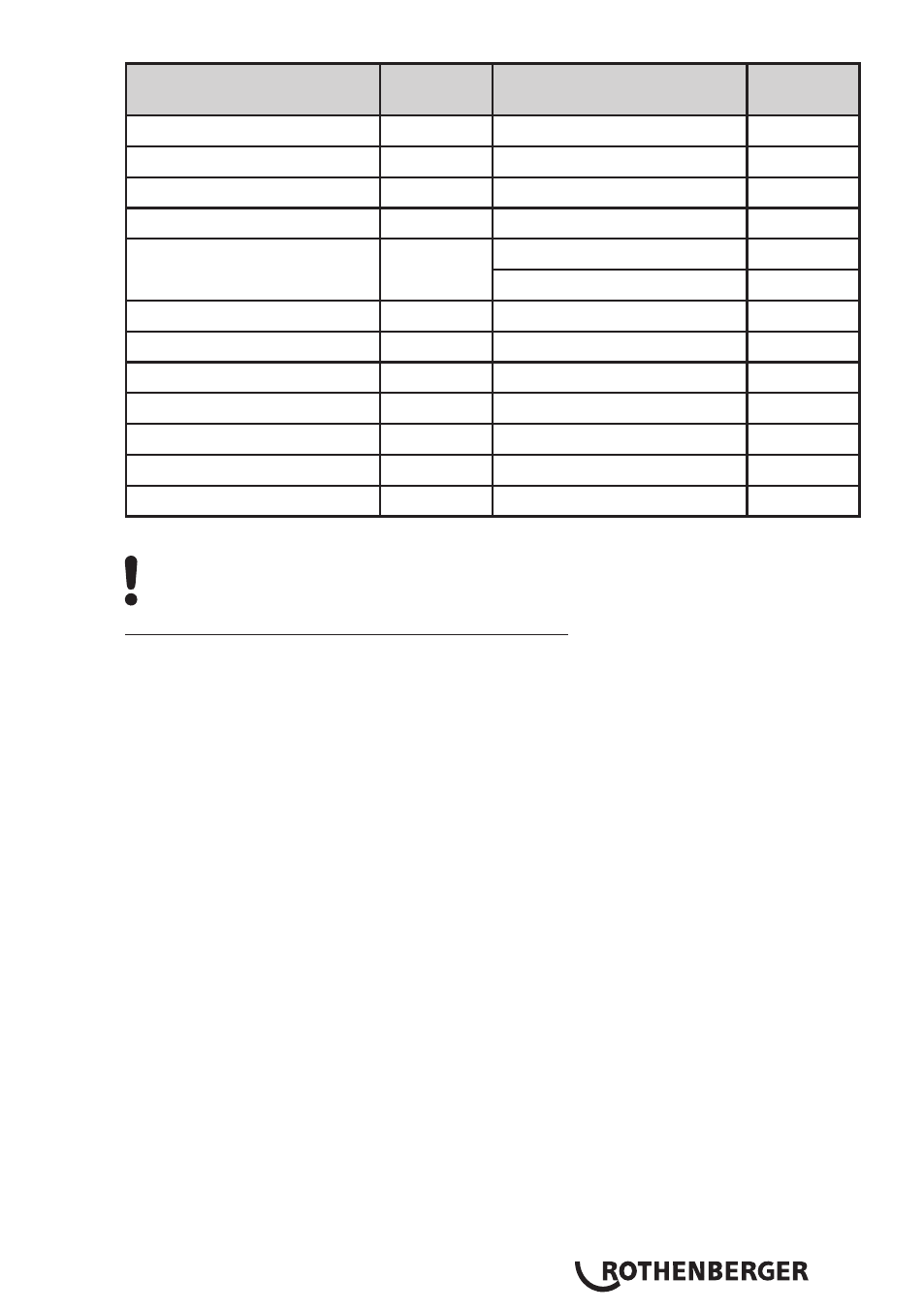

Figure 2 - Reference Table for Emisivity of Materials and finishes

Caution: Values in emissivity tables are only ever guideline values.

Understanding the basic concept of Thermal Imaging:

It is important to understand that a thermal image represents the temperature distribution on the

surface of an object. This is important to understand when looking for concealed objects, such as

pipes embedded within floors or walls. You cannot look through objects with a thermal camera,

but rather you can detect a transfer of hot or cold from behind or within a surface material. As

this temperature differentiation is absorbed within the surface material the ability to detect a

thermal image of a concealed temperature variation will diminish. It may be necessary to (for

instance) to start with a very cold floor, before turning on the heating element embedded within

the floor, in order to detect a temperature gradiant of the heating coils within. Once the floor

tile absorbs the heat with even distribution, it will no longer possible to detect the temperature

variations with your thermal camera. This would also apply to hot/cold pipes concealed within

walls.

NOTE: Actual temperature accuracy will vary, as the heat / cold is absorbed within the surface

material, as you are actually measuring the temperature on the surface material (not the pipe

concealed within).

Emissivity (

ε) is a coefficient to measure the ability of a material to emit infrared radiation. This is

a critical setting within any thermal camera, in order to provide an accurate calculation of vastly

different materials (see attached table above). There are numerous factors taken into account

when selecting the proper Emissivity, which include color, finish and texture. Generally speaking,

polished surfaces reflect more strongly than rough or matt surfaces made of the same material. It

is important to select the proper Emissivity in order to obtain the greatest thermal accuracy.

NOTE: Where the human eye can look through glass, glass has a reflective property to infrared

radiation. Your Thermal Imager therefore measures thermal radiation reflected off the glass, and

cannot detect temperature of viewed materials from behind the glass.

NOTE: Where the Thermal Imager will always visually indicate temperature variations through the

user’s choice of color pallets, the accuracy of actual temperature readings may vary when viewing

a variety of object with varying color and texture. Remember – every surface has a specific

Emissivity for optimum accuracy of temperature readings.