2 troubleshooting guide – Aalborg TIO Totalizer I/O Flow Monitor/Controller User Manual

Page 72

7.2

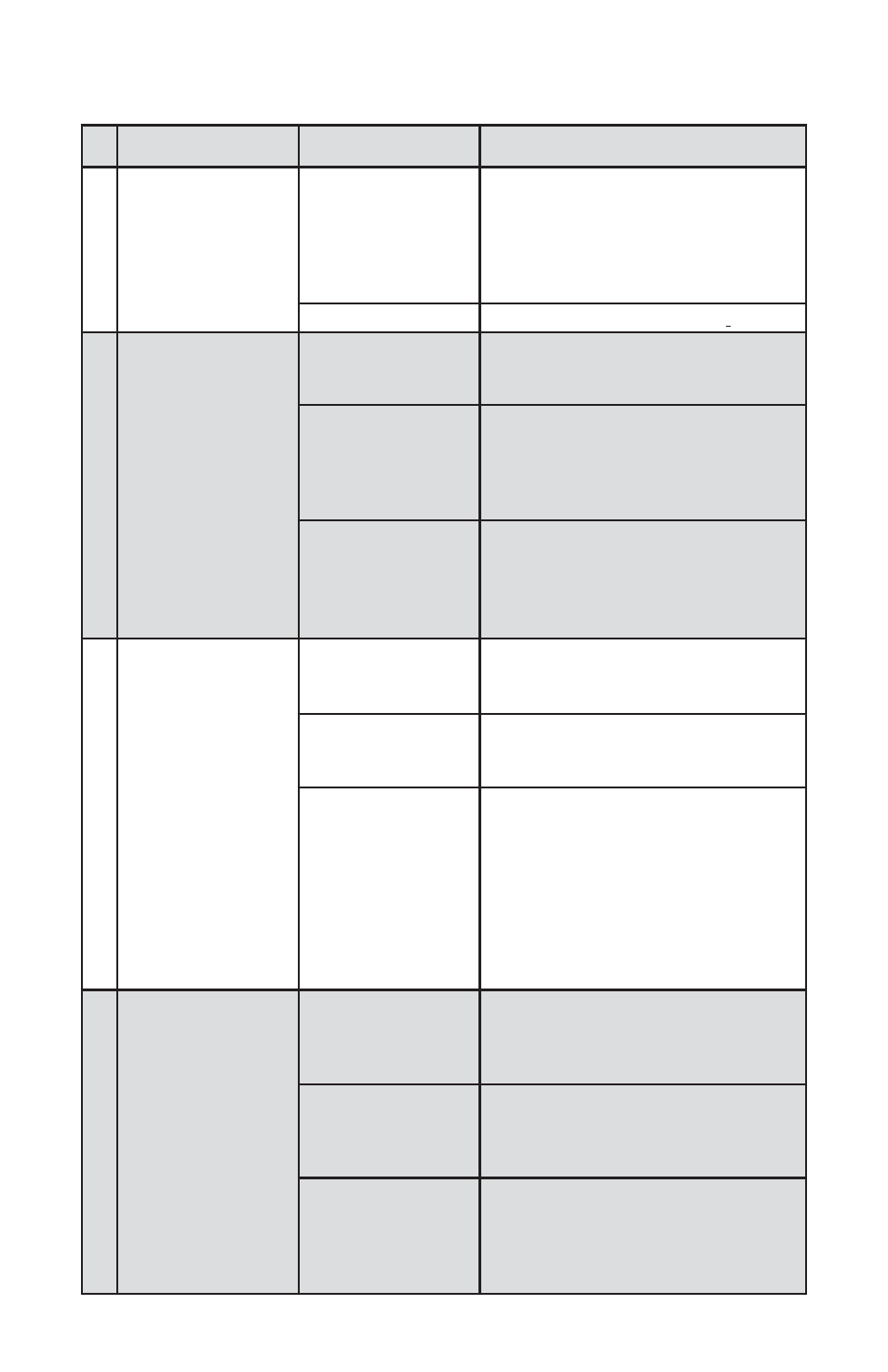

Troubleshooting Guide

69

NO.

INDICATION

LIKELY REASON

SOLUTION

1

LCD Display remains

blank when unit is

powered up. Status LED

is OFF

Power supply is bad or

polarity is reversed.

Measure voltage on pins 2 and 1 of the DB9

interface terminal connector. If voltage is

out of specified range, then replace power

supply with a new one. If polarity is

reversed (reading is negative) make correct

connection.

PC board is defective.

Return device to factory for repair.

2

LCD Displays flow read-

ing, but 4-20 mA set

point output signal

does not change

Wrong configuration of

J2 Input/Output

Jumpers

Check J2 jumper configuration (see Table

6.4)

External loop is open or

load resistance more

than 600 Ohm.

Check external connections to pins 5 and 6

of the DB9 interface terminal connector.

Make sure the loop resistance is less than

400 Ohm for 12Vdc power supply option

and 900 Ohm for 24Vdc power supply option.

4-20 mA circuitry is

burned out or damaged.

Using Key Pad, navigate to Submenu “

Device Diagnostic” and select submenu

“Analog Output Value”. Record the DAC

counts values and consult the factory with

findings.

3

Fluid flows through the

flow meter / controller,

but LCD Display and /or

Totalizer reading do not

respond to the flow.

The fluid flow rate is

below set Low flow cut-

off value.

Check settings for Low Flow Cut-Off value

and make required adjustment (see para-

graph 5.3.14 submenu “Low Flow Cut Off”).

Wrong configuration of

J2 Input/Output

Jumpers

Check J2 input jumper configuration (see

Table 6.4) If necessary contact factory for

additional help.

PC board is defective.

Using ESD precautions, measure voltage on

pins 4 and 6 of the DB9 interface terminal

connector. If voltage correlates with flow

meter / controller output signal, check ADC

counts: using Key Pad, navigate to

Submenu “Device Diagnostic” and select

submenu “ADC Input Counts”. Record the

ADC counts values and consult the factory

with findings.

4

Fluid flows through the

flow meter / controller,

LCD Display Flow Rate

reading responds to

flow, but Totalizer

reading is not changing.

The fluid flow rate is

below set “Totalizer #1

Flow Start” parameter

value.

Check settings for “Totalizer #1 Flow Start”

value and make required adjustment (see

paragraph 5.3.7.b submenu “Totalizer #1

Flow Start”).

Totalizer mode is dis-

abled

Check settings for “Totalizer #1 Mode”

parameter. Make sure Totalizer Mode set to

“Enabled” (see paragraph 5.3.7.a submenu

“Totalizer #1 Mode”).

Totalizer Power On

Delay parameter is set

to high value and

Totalizer is disabled by

firmware.

Check settings for “Totalizer Power On

Delay” (see paragraph 5.3.7.e submenu

“Totalizer #1 Power On Delay”). If settings

are too high, make required adjustment.