Dip s, Etting, Witches – Red Lion CUB5 User Manual

Page 3: Ptional, Ards, Nstalling, Eter, Adding option cards, Installation, Installation environment

3

2.0 S

ettinG

the

dip S

witcheS

SETTING THE INPUT DIP SWITCHES

The meter has four DIP switches for Input A and Input B that must be set

before applying power.

SWITCH 1

LOGIC: Input A trigger levels V

IL

= 1.25 V max.;

V

IH

= 2.75 V min.; V

MAX

= 28 VDC

MAG: 200 mV peak input sensitivity; 100 mV

hysteresis; maximum input voltage: ±40 V peak

(28 Vrms); Must also have SRC switch ON.

(Not recommended with counting applications.)

SWITCH 2

SNK.: Adds internal 7.8 KΩ pull-up resistor to +9 to

28 VDC, I

MAX

= 3.8 mA.

SRC.: Adds internal 3.9 KΩ pull-down resistor,

7.2 mA max. @ 28 VDC max.

SWITCHES 3 and 4

HI Frequency: Removes damping capacitor and allows max. frequency.

LO Frequency: Adds a damping capacitor for switch contact bounce. Limits

input frequency to 50 Hz and input pulse widths to 10 msec.

To access the switches, remove the rear cover of the meter as described

below. A bank of 4 switches is located in the upper right hand corner. After

setting the switches, install any optional plug-in cards before replacing the rear

cover (see next section).

Warning: Exposed line voltage exists on the circuit boards. Remove

all power to the meter and load circuits before accessing inside of

the meter.

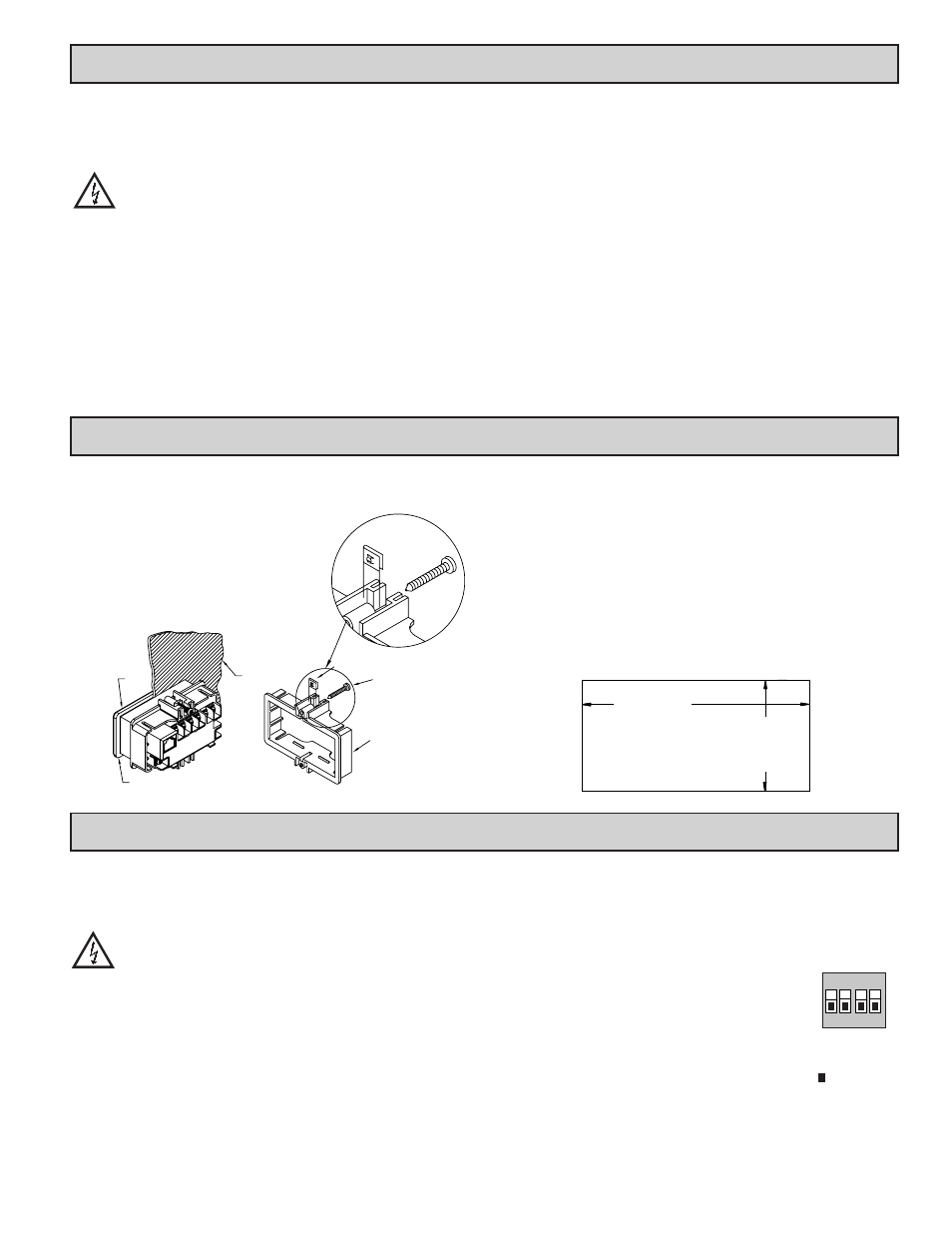

REMOVING THE REAR COVER

To remove the rear cover, locate the cover locking tab below the 2nd and 3rd

input terminals. To release the tab, insert a small, flat blade screwdriver between

the tab and the plastic wall below the terminals. Inserting the screwdriver will

provide enough pressure to release the tab locks. To replace the cover, align the

cover with the input terminals and press down until the cover snaps into place.

4

3

2

1

ON

Input B LO Freq.

Input

A

LO Freq.

Input

A

SRC.

Input

A

MAG.

HI Freq.

HI Freq.

SNK.

Logic

Factory Setting

o

ptional

p

luG

-

in

c

ardS

ADDING OPTION CARDS

The CUB5 meters can be fitted with optional output cards and/or serial

communications cards. The details for the plug-in cards can be reviewed in the

specification section below. The plug-in cards, that are sold separately,

can be

installed initially or at a later date.

WARNING: Disconnect all power to the unit before installing

Plug-in card.

SINGLE RELAY OUTPUT CARD (One setpoint only)

Type: Single FORM-C relay

Isolation To Sensor & User Input Commons: 1400 Vrms for 1 min.

Working Voltage: 150 Vrms

Contact Rating: 1 amp @ 30 VDC resistive; 0.3 amp @ 125 VAC resistive

Life Expectancy: 100,000 minimum operations

Response Time:

Turn On Time: 4 msec. max.

Turn Off Time: 4 msec. max.

DUAL SINKING OUTPUT CARD (One or two setpoints)

Type: Non-isolated switched DC, N Channel open drain MOSFET

Current Rating: 100 mA max.

V

DS ON

: 0.7 V @ 100 mA

V

DS MAX

: 30 VDC

Offstate Leakage Current: 0.5 mA max.

RS485 SERIAL COMMUNICATIONS CARD

Type: RS485 multi-point balanced interface (non-isolated)

Baud Rate: 300 to 38.4k

Data Format: 7/8 bits; odd, even, or no parity

Bus Address: 0 to 99; max 32 meters per line

Transmit Delay: Selectable, 2 msec min. or 50 msec min.

RS232 SERIAL COMMUNICATIONS CARD

Type: RS232 half duplex (non-isolated)

Baud Rate: 300 to 38.4k

Data Format: 7/8 bits; odd, even, or no parity

USB PROGRAMMING CARD

Type: USB virtual comms port

Connection: Type B

Baud Rate: 300 to 38.4k

Unit Address: 0 to 99

1.0 i

nStallinG

the

M

eter

INSTALLATION

The meter meets NEMA 4X/IP65 requirements when properly installed. The

unit is intended to be mounted into an enclosed panel. Prepare the panel cutout

to the dimensions shown. Remove the panel latch from the

unit. Slide the panel gasket over the rear of the unit to

the back of the bezel. The unit should be installed

fully assembled. Insert the unit into the panel

cutout.

While holding the unit in place, push the panel

latch over the rear of the unit so that the tabs of the

panel latch engage in the slots on the case. The panel latch should be engaged in

the farthest forward slot possible. To achieve a proper seal, tighten the latch

screws evenly until the unit is snug in the panel (Torque to approx. 28 to 36 in-oz

[0.202 to 0.26 N-m]). Do not over-tighten the screws.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the operating

temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

The bezel should only be cleaned with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the

keypad of the unit.

2.68

(68 )

+.8

1.30

-.0

(33 )

-.000

+.6

-.0

-.000

+.024

+.025

PANEL

GASKET

BEZEL

PANEL

MOUNTING SCREW

NUT FASTENER

MOUNTING CLIP