Maintenance – JKS OGS128 User Manual

Page 3

JKSOGS128

JKS Adjustable HD Trackbar Installation

Page 3

Steering Wheel

Â

Have a partner turn the steering wheel in

small increments to shift the vehicle chassis

side-to-side.

Â

After each adjustment, have your partner

hold the steering wheel steady while you take

measurements.

4. SET ADJUSTABLE TRACKBAR LENGTH

AND MOUNT TO AXLE

Using a 1/2” drill bit, enlarge the original mounting

hole on the factory axle bracket.

IMPORTANT: Length of Adjustable Trackbar must be

set with axle housing perfectly centered and the ve-

hicle at normal ride height.

With the axle housing centered beneath the chas-

sis, adjust the length of Adjustable Trackbar by

rotating the axle end until the bushing aligns with

the mounting holes on the axle bracket.

Apply anti-seize lubricant to threads of 1/2” x

2-1/2” Bolt (D).

Install Axle End (C) of Adjustable Trackbar to the

axle bracket and secure with 1/2” x 2-1/2” Bolt (D)

and 1/2” Flanged Locking Nut (G).

Take measurements again to ensure axle housing

is perfectly centered and make any final adjust-

ments if necessary.

Check the Chassis End (A) of Adjustable Trackbar

to ensure it is aligned with the chassis rail bracket.

If necessary, rotate fore/aft until the space be-

tween the trackbar and chassis rail bracket is

even.

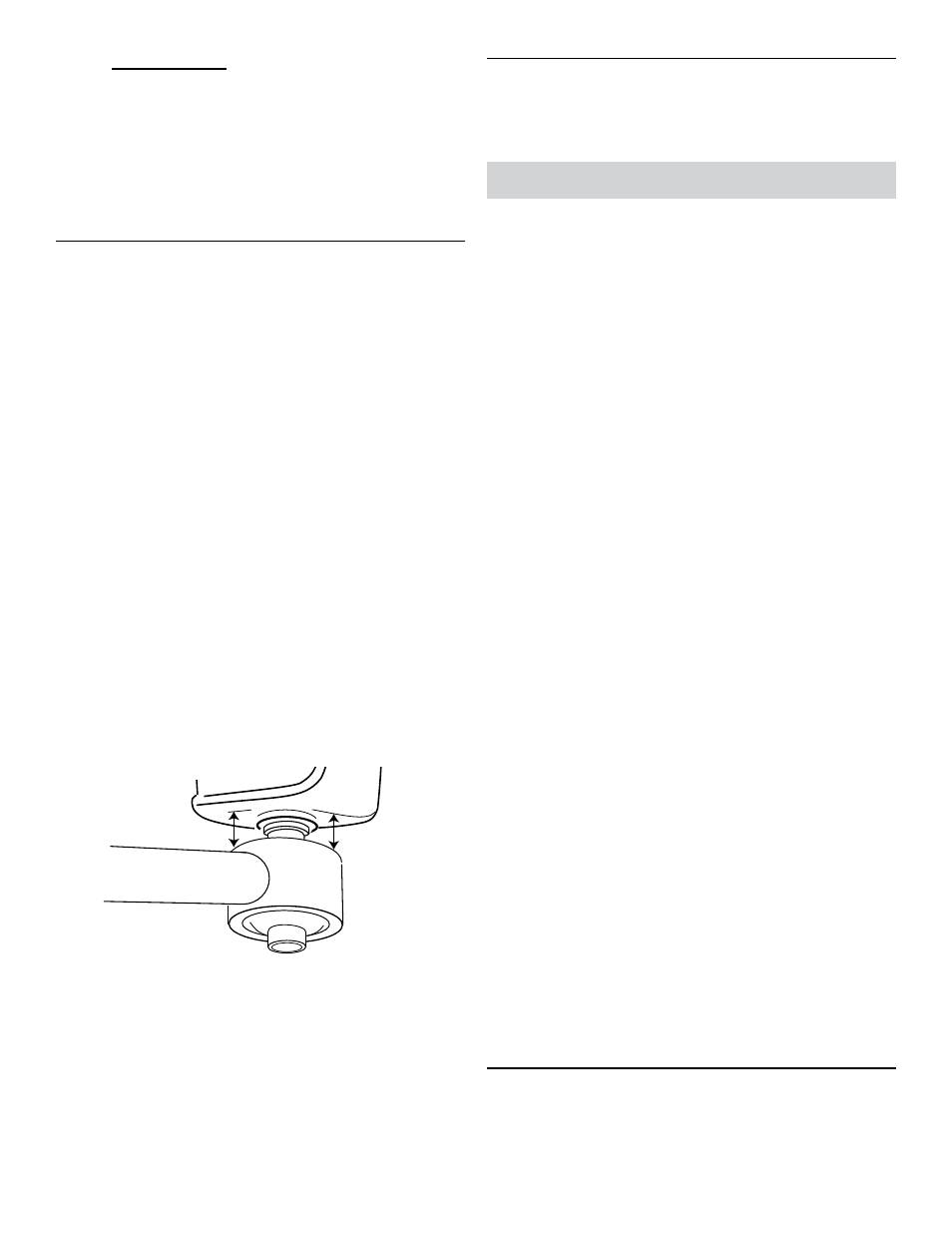

IMPORTANT: The Chassis End of Adjustable Trackbar

must be in the “neutral” position (as illustrated above)

before the Jam Nut is tightened.

Once all adjustments are complete, fully tighten

the Jam Nut (B) to prevent Adjustable Trackbar

length from changing. HINT: It may be easier to

tighten Jam Nut with the Adjustable Trackbar re-

moved from the vehicle.

Tighten the 1/2” x 2-1/2” Bolt (D) on axle bracket to

65 ft-lb. using a torque wrench.

5. LUBRICATE ADJUSTABLE TRACKBAR

Lubricate the Grease Zerk (N) at the chassis end

of Adjustable Trackbar using common wheel bear-

ing grease or equivalent.

Maintenance

Re-torque fasteners after driving 150 miles. Continue to

check torque specifications as part of regular vehicle main-

tenance routine.

The chassis end of the Adjustable Trackbar features a

spherical Nylatron bushing which is greaseable, adjustable

and rebuildable.

Lubrication

Lubricate the bushing via the Grease Zerk (N)

regularly as part of vehicle maintenance schedule.

Use common wheel bearing grease or equivalent.

Bushing Preload

The spherical Flex Joint is factory preloaded to 15

ft-lbs. and no adjustments are necessary at time

of installation. In the unlikely occurrence that the

bushing begins to loosen up over time, the user

can tighten the Preload Ring (I) to eliminate any

slop.

To adjust bushing preload, first remove the Set

Screw (O) to unlock the Preload Ring (I). Then

tighten the Preload Ring to 15 ft-lbs. using a torque

wrench. Re-install the Set Screw to lock the Pre

load Ring.

JKS strongly recommends the use of Flex Joint

Tool # SM-FJL-TOOL to adjust the Preload Ring (I).

This special spanner socket is available directly

from Summit Machine by calling 877-533-7557.

Replacement Parts

Flex Joints are designed for maximum longevity

and it is extremely unlikely that any parts will

wear out. Just in case, all replacement parts are

available directly from JKS Manufacturing on our

website at www.jksmfg.com.

Cleaning

Regular cleaning with pressurized water is

recommended to maximize ease of operation and

reliability. Always lubricate afterwards to evacuate

any moisture.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 10/31/2013