Installation – JKS 9400 User Manual

Page 2

JKS5006-5007-9300-9400

JKS Quick Diconnect Installation

2 Page

Installation

1. REMOVE ORIGINAL EQUIPMENT (OE)

SWAYBAR LINKS

Remove front swaybar drop links per the fac-

tory service manual instructions for your vehicle.

Retain the original mounting hardware as it is

required for Quick Disconnect installation.

2. MOUNT UPPER ENDS TO SWAYBAR

Install Upper Female End (E) of Quick Disconnect

to outboard side of swaybar, ensuring Grease Zerk

(C) is facing forward.

IMPORTANT: Female end must be mounted on top to

prevent it from collecting mud and debris.

Secure Upper End (E) with the original tapered

mounting bolt and hardware. Tighten to 40-50 ft-

lb. using a torque wrench.

3. MOUNT LOWER ENDS TO AXLE

Install Lower Male End (B) of Quick Disconnect to

the front axle U-bolt plates, ensuring Grease Zerk

(C) is facing forward.

Secure Lower End (B) with the original mounting

hardware. Tighten until all threads on nut engage

the OE mounting stud, but do NOT overtighten

polyurethane bushing.

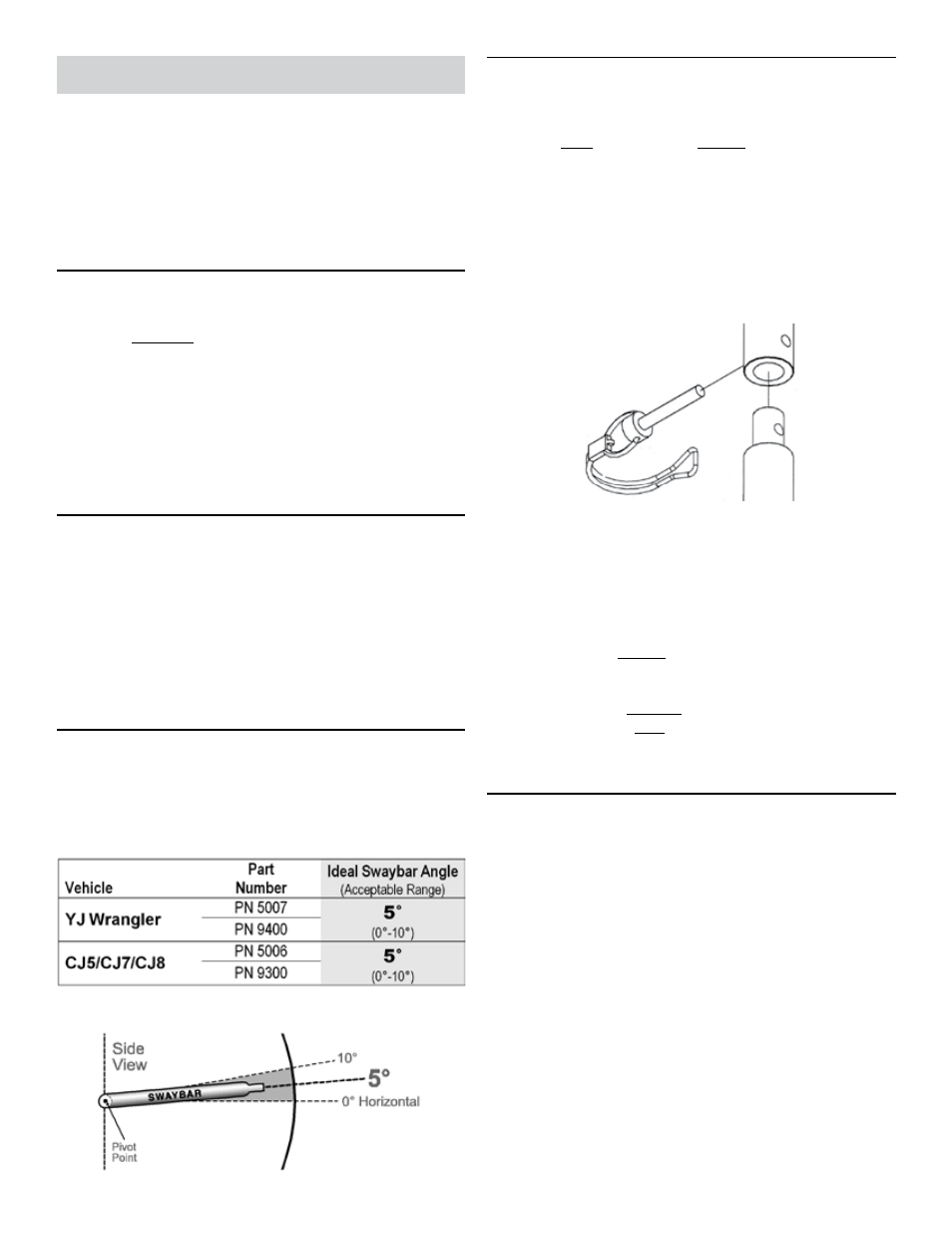

4. MEASURE ANGLE OF SWAYBAR

With the Quick Disconnects installed, and the

vehicle on level ground and at normal ride height,

measure swaybar angle to ensure it complies with

the Acceptable Range below.

HINT: See illustration of swaybar angle

5. DISCONNECT AND RECONNECT ENDS

OF QUICK DISCONNECT

HINT: Always disconnect and reconnect swaybar with

vehicle on level ground and at normal ride height.

Remove the Stainless Steel Lynch Pins (D) to

disconnect swaybar.

Rotate the swaybar up and out of the way.

IMPORTANT: When disconnected, the swaybar must

be secured to vehicle chassis to prevent interference

with suspension components or axle. Use plastic wire

ties, bungee cord or equivalent.

To reconnect, rotate swaybar down and align both

ends of Quick Disconnect so that male and female

union slides together.

Insert Stainless Steel Lynch Pin (D) through the

male/female union to secure Quick Disconnect

ends and lock the lynch pin in place.

HINT: It is normal to experience some difficulty

when removing or inserting lynch pins following

initial installation. Vehicle must be driven for a

few days to break in Quick Disconnects and allow

lynch pins to seat. With use, lynch pins will be-

come easier to remove/insert.

6. LUBRICATE QUICK DISCONNECTS

Flush mount grease zerks require special grease gun at-

tachment available at any auto parts store – use Lincoln®

PN 83278 or equivalent.

Lubricate all Grease Zerk fittings (C) on Quick

Disconnects immediately after installation using

common wheel bearing grease or equivalent.