X” – 1/4 ” = ride height, Do not exceed – JKS 2700 User Manual

Page 7

JKS AC

OS Pro™ Installation

PN 2700

Page 7 of 8

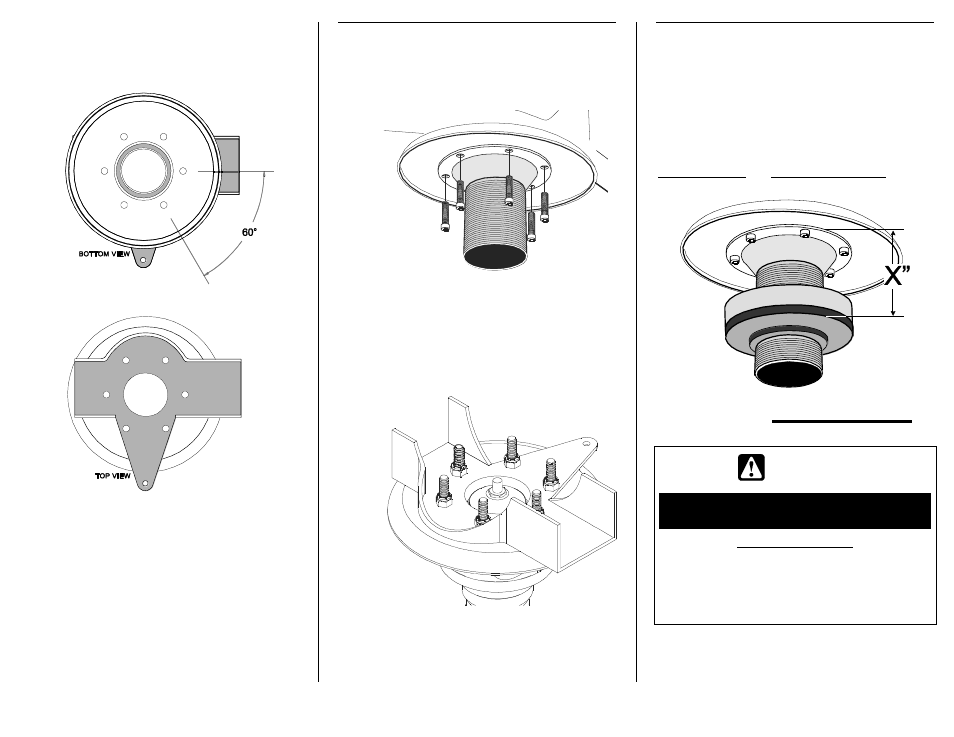

Using the Main Body (B) as a template,

accurately mark all six hole locations on the

upper spring mount using a transfer punch or

equivalent. HINT: Hole locations should align

with spring mount bracket as indicated below.

Using a 1/4” bit, drill a pilot hole at each hole

location. Enlarge each hole with a 3/8” drill bit.

Paint any exposed metal on the upper spring

mount to prevent corrosion.

5. INSTALL MAIN BODY OF ACOS

PRO

ON UPPER SPRING MOUNT

Position the Main Body (B) against the bottom

of the upper spring mount and align the

mounting holes.

Insert a 5/16” x 1-1/4” Cap Bolt (C) through

each hole. Loosely secur

e with a 5/16” Nylock

Nut (D) from above the spring mount.

HINT: It is not necessary to install the supplied

Reinforcement Ring (A) on rear applications.

Once all six bolts have been installed, tighten

the 5/16” Nylock Nuts (D) to 40 ft-lbs. using a

torque wrench.

6. SET ADJUSTER RING FOR

DESIRED RIDE HEIGHT

Apply spray lubricant to threads of Main Body

(B). Install Adjuster Ring (E) by threading

clockwise onto Main Body (B).

Slide Isolator Pad (G) onto Main Body until flush

with Adjuster Ring (E).

IMPORTANT: Vehicle ride height is determined

by measuring the distance between the

top of Main Body and bottom of Isolator Pad,

and then subtracting 1

/4” (0.25 in.).

X

” – 1/4” = RIDE HEIGHT *

* Represents increase in ride height over OE suspension

WARNING

DO NOT EXCEED

MAXIMUM RANGE OF ADJUSTMENT

ADJUSTMENT RANGE

MINIMUM: 1-3/4

” (1.750 in.)

MAXIMUM: 3-5/8

” (3.625 in.) **

** MAXIMUM: 2-

1/8” (2.125 in.) if Main Body

was shortened 1-

1/2” in step 3

Rotate Adjuster Ring (E) to desired position and

tighten the recessed

3/8” x 1-1/4” Cap Bolt (F)

to lock in place.