JKS 2700 User Manual

Page 4

JKS AC

OS Pro™ Installation

PN 2700

Page 4 of 8

7. INSTALL BUMP SHOCK ON

MAIN BODY OF ACOS PRO

Apply a drop of medium strength thread locking

compound to bottom few threads of

Main Body (B).

Completely thread the Bump Shock Adapter (H)

onto Main Body (B) until snug.

Apply anti-seize lubricant to threads of

Bump Shock Assembly (J). Completely

thread the Bump Shock Nut (I) onto Bump

Shock Assembly (J).

Completely thread Bump Shock Assembly (J)

with Bump Shock Nut (I) into Bump Shock

Adapter (H) as far as possible.

8. RE-INSTALL FRONT COIL SPRINGS

Re-install the front coil springs per the factory

service manual instructions for your vehicle.

HINT: A coil spring compressor is useful for

installation.

Also re-install any of the components that were

removed during Step 1 of this installation.

ATTENTION INSTALLER

IMPORTANT NOTE REGARDING

SHOCK ABSORBERS

To prevent the coil springs from becoming

unseated during maximum suspension extension,

correct length shock absorbers must be installed.

9. ADJUST BUMP SHOCK POSITION

The ideal bump shock position is determined by the

vehicle suspension and varies for each application.

To properly set the bump shock position for

your vehicle, you must first decide the point at

which suspension compression should be

limited. Take into consideration coil springs,

shock absorbers, tire clearance, or any other

factors that cause the vehicle to bottom out.

IMPORTANT: Because it replaces the

original rubber bump stop, the bump shock

should determine the limit of compression

travel. The bump shock should be fully

compressed when the suspension reaches

maximum desired compression.

With the vehicle on level ground and the

suspension at full droop, extend the Bump

Shock Assembly (J) to the desired position.

Once the Bump Shock Assembly (J) is properly

adjusted for your application, lock in place by

turning the Bump Shock Nut (I) clockwise until it

contacts the Bump Shock Adapter (H).

IMPORTANT: The suspension must be fully

cycled to test for bump shock alignment and

interference issues before the vehicle can

be safely operated. The bump shock must

contact the center portion of the lower

spring pad at full compression, and there

should be no interference between the bump

shock and coil spring at full extension.

If you encounter any interference issues,

contact JKS Manufacturing immediately for

technical assistance.

JKS Technical Department

Phone

877-533-7557

Operation

Ride Height & Bump Shock Adjustments

Future ride height and bump shock adjustments should

be made with NO LOAD on the front coil springs, and

the suspension at FULL DROOP.

NEVER TURN Adjuster Ring (E) while under tension

and ALWAYS APPLY SPRAY LUBRICANT to threads

of Main Body (B) or Bump Shock Assembly (J) before

adjusting.

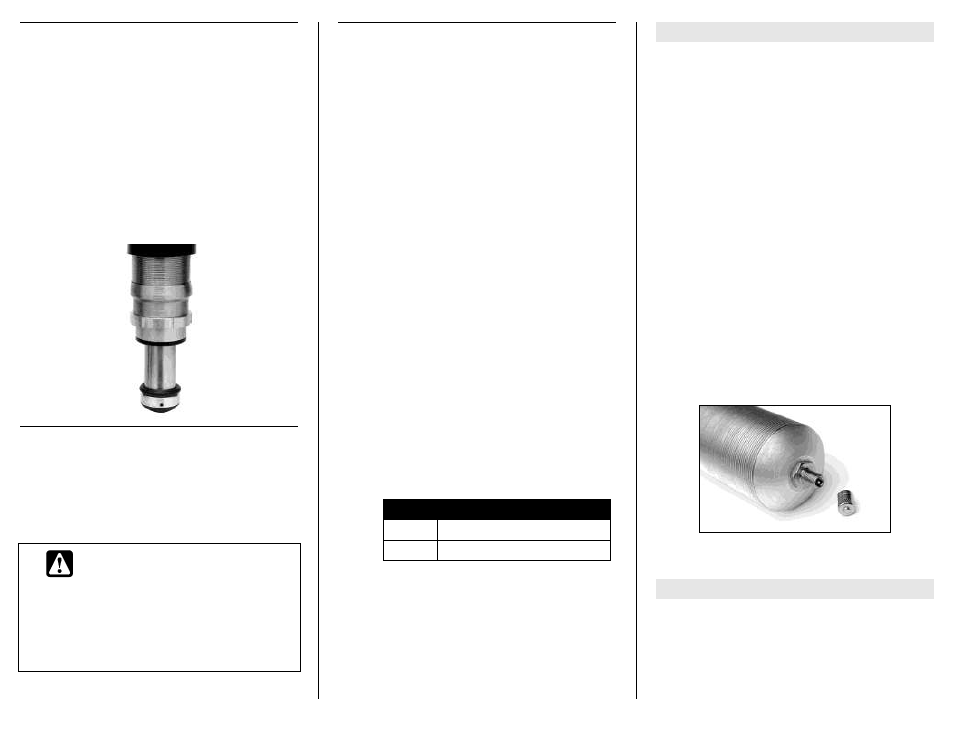

Bump Shock Pressure

The Bump Shock Assembly (J) is pre-charged with the

proper amount of Nitrogen gas to suit most applications.

IT SHOULD NOT BE NECESSARY TO ADJUST BUMP

SHOCK PRESSURE ON MOST VEHICLES.

The Nitrogen charge is factory preset at 150 psi. For

applications that require a higher or lower compression

rate, the gas pressure can be manually adjusted to a

minimum of 100 psi and a maximum of 200 psi.

To adjust pressure, the bump shock assembly must be

removed from the vehicle. Nitrogen pressure is adjusted

through the Schrader valve on top of the bump shock.

Care should be taken when discharging the bump shock

to ensure that no oil is lost. Most shops that service off-

road racing or motorcycle shock absorbers can adjust

bump shock pressure.

Maintenance

Regular cleaning with pressurized water is

recommended to maximize ease of operation and

reliability.