American Dryer Corp. AD-15 Phase 7 User Manual

Page 8

6

American Dryer Corp.

113243-1

CAUTION:

This dryer produces combustible lint and must

be exhausted to the outdoors.

When possible, it is suggested to provide a separate (single)

exhaust duct for each dryer.

CAUTION:

IMPROPERLY SIZED OR INSTALLED

EXHAUST DUCTWORK CAN CREATE A

POTENTIAL FIRE HAZARD.

The exhaust ductwork should be laid out in such a way that

the ductwork travels as directly as possible to the outdoors

with as few turns as possible. The shape of the ductwork is

not critical provided that the minimum cross section area is

maintained. Single or independent dryer venting is

recommended.

It is suggested that the use of 90° turns be avoided; use 30°

or 45° angles instead.

The ductwork should be smooth inside with no projections

from sheet metal screws or other obstructions, which will

collect lint. When adding ducts, the ducts to be added should

overlap the duct to which it is connected. ALL ductwork joints

must be taped to prevent moisture and lint from escaping

into the building. Additionally, inspection doors should be

installed at strategic points in the exhaust ductwork for

periodic inspection and cleaning.

IMPORTANT:

When connecting ductwork to the dryer exhaust

duct, be sure that when screws are used they

DO NOT restrict the operation (both opening

and closing) of the damper.

NOTE:

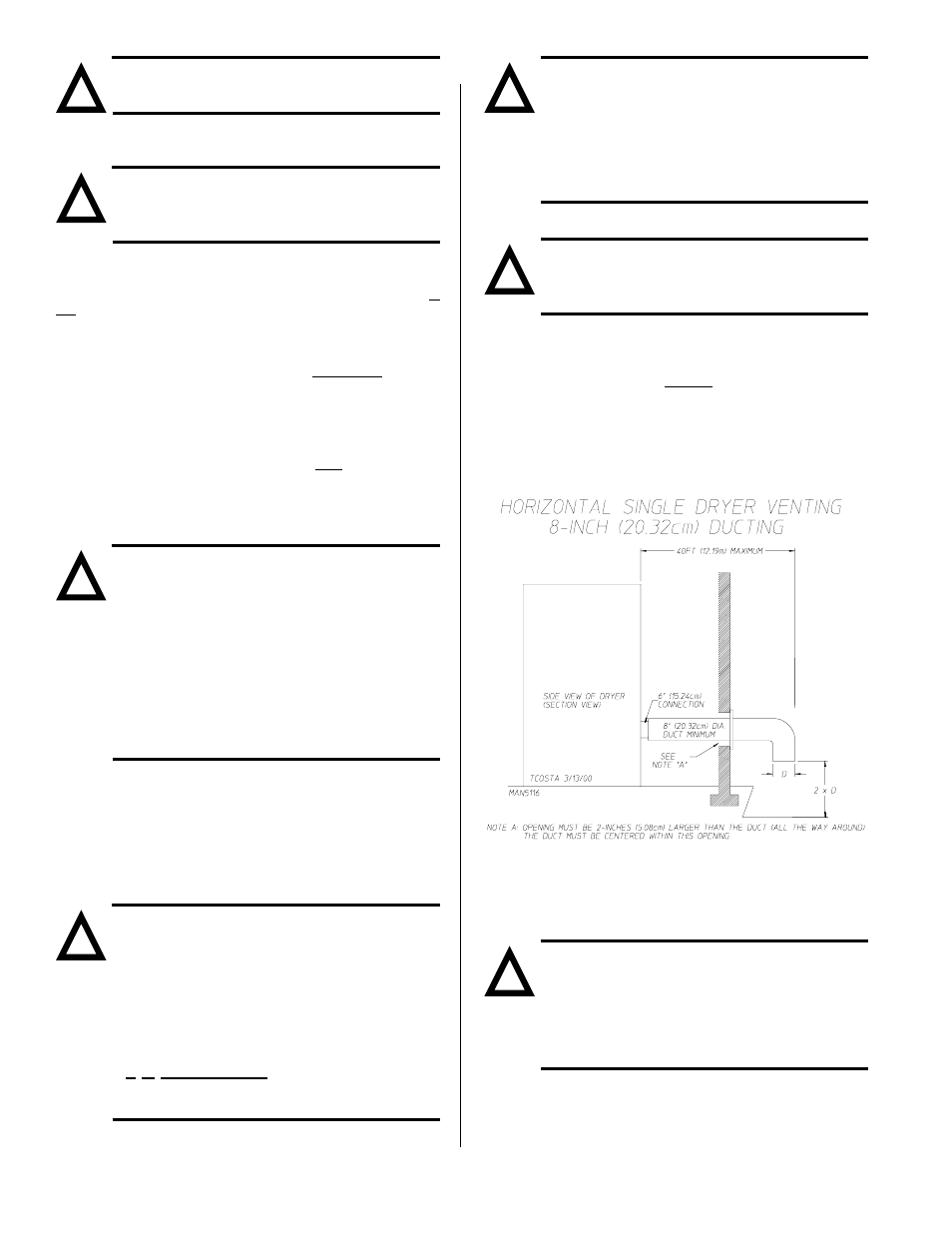

When the exhaust ductwork passes through a

wall, ceiling, or roof made of combustible

materials, the opening must be 2-inches (5.08

cm) larger than the duct (all the way around).

The duct must be centered within this opening.

To protect the outside end of the horizontal ductwork from the

weather, a 90° elbow bent downward should be installed

where the exhaust exits the building. If the ductwork travels

vertically up through the roof, it should be protected from the

weather by using a 180° turn to point the opening downward.

In either case, allow at least twice the diameter of the duct

between the duct opening and the nearest obstruction (i.e.,

roof or ground level).

IMPORTANT:

DO NOT use screens, louvers, or caps on the

outside opening of the exhaust ductwork.

Exhaust back pressure measured by a

manometer at the dryer exhaust duct area must

be no less than 0 and must not exceed 0.3

inches (0.74 mb) of water column (W.C.).

It is recommended that exhaust or booster

fans not be used in the exhaust ductwork

system.

NOTE:

As per the National Fuel Gas Code, Exhaust

ducts for type 2 clothes dryers shall be

constructed of sheet metal or other

noncombustible material. Such ducts shall be

equivalent in strength and corrosion resistance

to ducts made of galvanized sheet steel not less

than 0.0195-inches (26 gauge [0.05 mm]) thick.

SINGLE DRYER VENTING

IMPORTANT:

For exhaust duct runs over 40 feet (12.19

meters) a minimum size of 10-inches (25.4 cm)

must be used.

HORIZONTAL VENTING

When horizontal single 8-inch (20.32 cm) venting is used,

the ductwork to the outlet cannot exceed 40 feet (12.19

meters), refer to Illus. A below. This calculation of 40 feet

(12.19 meters) compensates or allows for the use of a

maximum of only one (1) elbow (which is the outside outlet

protection).

Illus. A

If the length of the duct run or quantity of elbows used exceeds

the above noted specifications, the cross section area of the

ductwork must be increased in proportion to the number of

elbows or duct run added.

IMPORTANT:

For extended ductwork runs, the cross section

area of the duct can only be increased to an

extent. For extended ductwork runs, a

professional heating, ventilating, and

air-conditioning (HVAC) firm should be

consulted for proper venting information.

!

!

!

!

!

!

!