American Dryer Corp. AD-15 Phase 7 User Manual

Page 18

16

American Dryer Corp.

113243-1

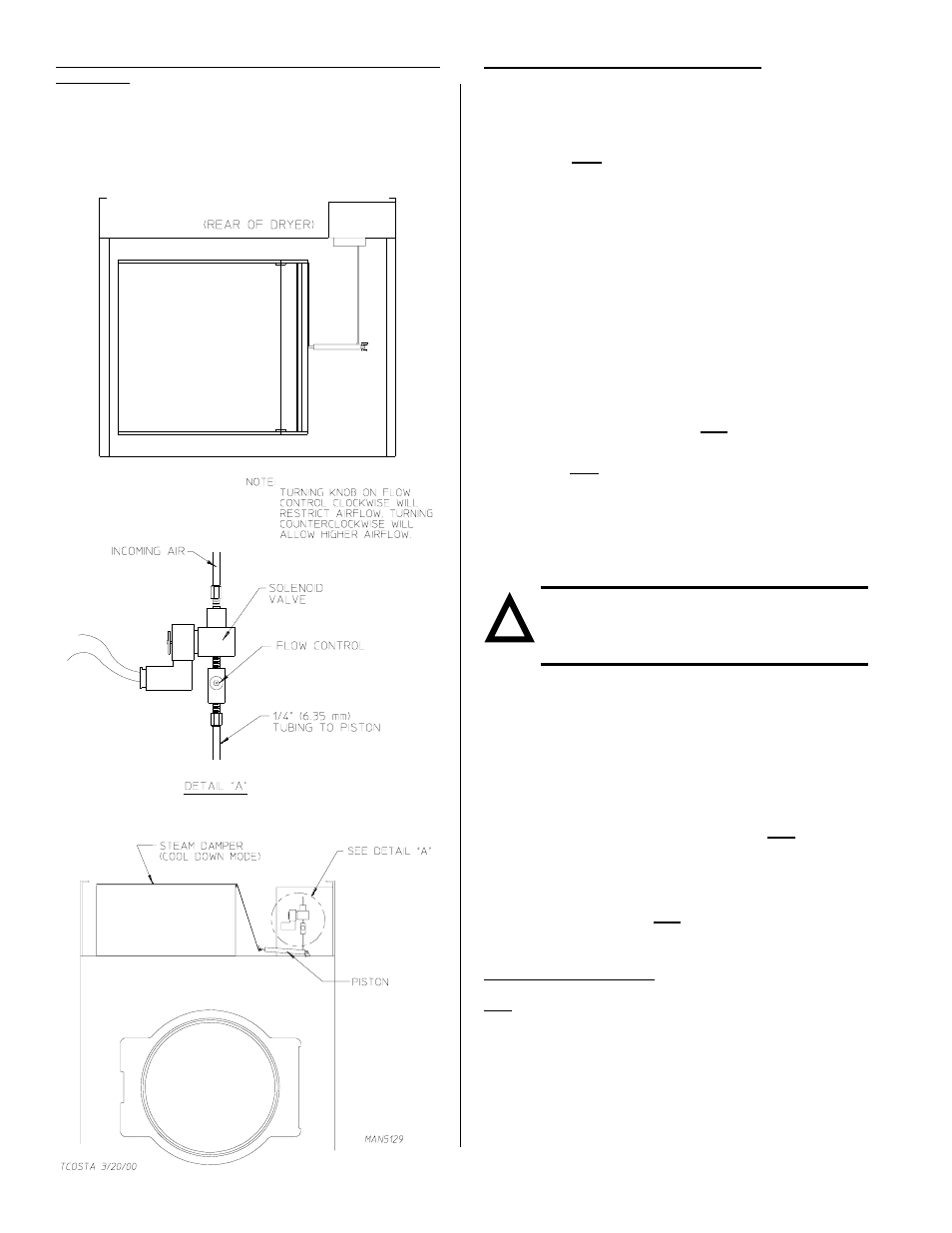

Steam Damper Air Piston (Flow Control) Operation

Adjustment

Damper operation was tested and adjusted prior to shipping

at 80 psi (5.51 bar). If damper air adjustment is necessary,

locate the flow control valve and make the necessary

adjustments as noted below.

PREOPERATIONAL TESTS

ALL dryers are thoroughly tested and inspected before leaving

the factory. However, a preoperational test should be

performed before the dryer is publicly used. It is possible

that adjustments have changed in transit or due to marginal

location (installation) conditions.

Turn on electrical power to the dryer.

Refer to the Operating Instructions for starting your particular

model dryer.

PREPARATION FOR OPERATION/START-UP

The following items should be checked before attempting to

operate the dryer:

Read ALL CAUTION, WARNING, and

DIRECTION labels attached to the dryer.

Check incoming supply voltage to be sure that it is

the same as indicated on the dryer data label.

GAS MODELS - check to ensure that the dryer is

connected to the type of heat/gas indicated on the

dryer data label.

GAS AND ELECTRIC MODELS - the sail switch

damper assembly was installed and adjusted at

the factory prior to shipping. However, each sail

switch adjustment must be checked to ensure that

this important safety control is functioning.

Check bolts, nuts, screws, terminals, and fittings

for tightness.

GAS MODELS - be sure that ALL gas shutoff valves

are in the open position.

Check ALL back guard panels and service box

covers have been replaced.

Make sure the lint coop support bracket has been

removed.

Check the lint door to ensure that it is closed and

secured in place.

IMPORTANT:

If during installation the lint door safety chain

was disconnected, it must be reconnected or

personal injury may result.

Rotate the basket (tumbler/drum) by hand to be

sure it moves freely.

Check bolts, nuts, screws, terminals, and fittings

for security.

STEAM MODELS - check to ensure that a clean,

dry, and regulated air supply (80 psi [5.51 bar]) is

on the dryer (with air-operated damper system

only).

STEAM MODELS - check to ensure ALL steam

shutoff valves are open.

STEAM MODELS - check steam damper operation.

Check basket (tumbler) bearing setscrews to

ensure that they are ALL tight.

!