Troubleshooting – Sterlco ST500 Series Central Granulator User Manual

Page 81

81

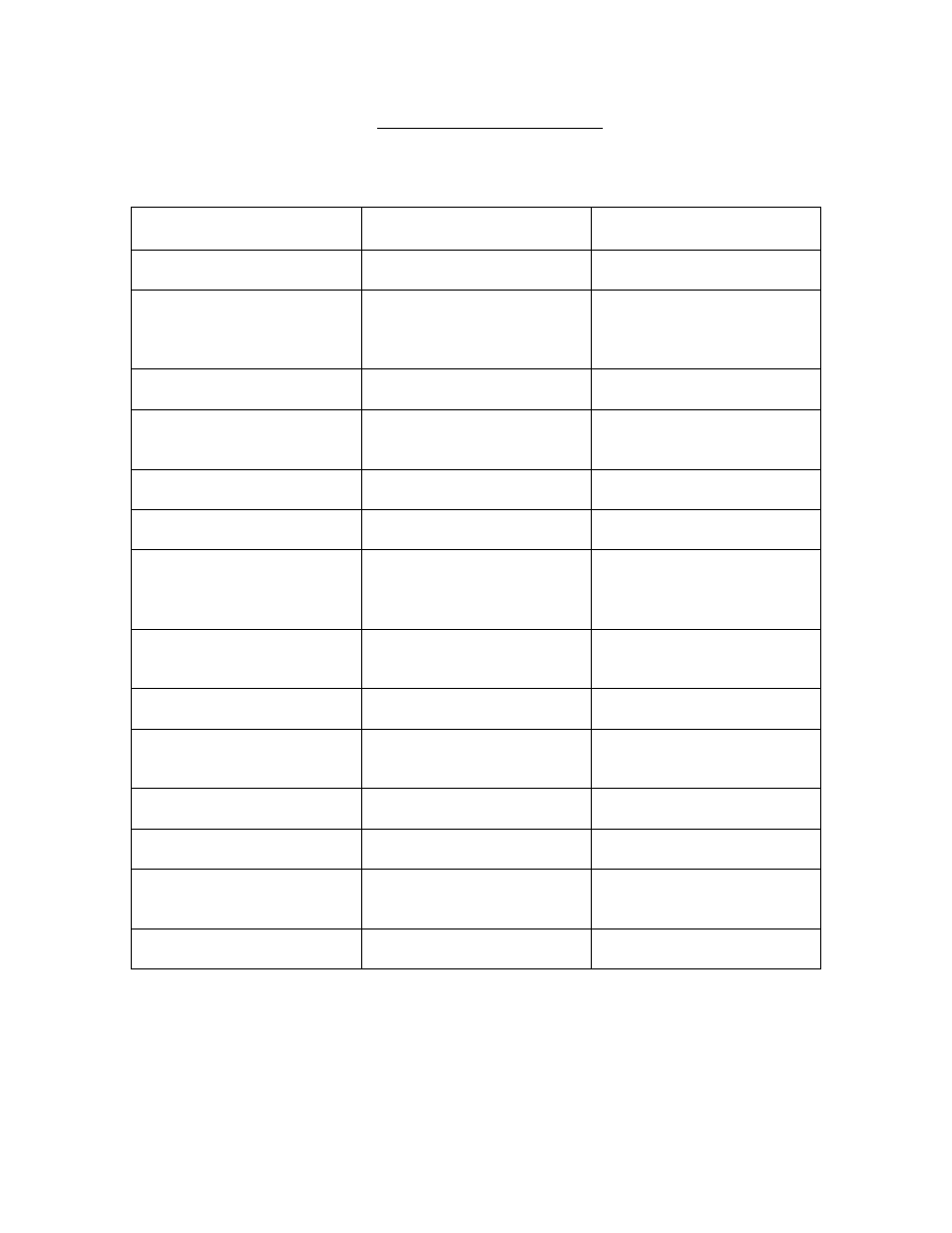

TROUBLESHOOTING

SECTION 7-3

Mechanical Faults

PROBLEM

Mechanical Faults

PROBABLE CAUSE

REMEDY

A. Bearing overheating

1. Excessive wear on the V-

Belt drive

1. Check belt tension and

adjust as necessary

2. Inadequate lubrication

2. Check lubrication frequency

and the recommended

lubricants in motor and rotor

bearings

3. Dirt/Contamination in

bearing

3. Eliminate source of

contamination

B. Visible cracks in knives

1. Incorrect grinding

procedure or incorrect

grinding wheels in use

1. Check grinding procedures

and contact a STERLING

Service Engineer

C. Knives moving on seats

1. Uneven knifes seat surfaces 1. Clean knife seats to provide

maximum bearing surface

2. Loose knife screws

2. Tighten to correct torque,

per section 4

3. Stretched knife screws

3. Knife screws should not be

used more than six times.

Renew them if there is

evidence of stretching

D. Knives breaking

1. Possibly due to cracks

caused by incorrect grinding

1. Refer to problem B.

“Visible cracks in knives”

(above left)

2. Abnormally heavy material 2. Contact a STERLING

Service Engineer

3. Contaminated input

material

3. Inspect the material for

contaminates and foreign

matter

E. Excessive knife wear

1. Open knife setting

1. Reset as detailed in

alternate material

2. Abrasive materials

2. Contact a STERLING

Service Engineer

F. Screens wearing

1. Incorrectly seated

1. Check that the screen is

seated correctly and fully on

its cradle

2. Abrasive materials being

granulated

2. Obtain special alloy or heat

treated screens