Operation – Sterlco ST500 Series Central Granulator User Manual

Page 63

63

OPERATION

SECTION 5-3

Normal Operation

Never reach beyond the hopper curtain while the machine is running.

To clear a jam, refer to the procedure for clearing a jammed cutting chamber, which follows

in this section. Avoid excessive feed rates. Feed the machine by placing the plastic pieces

into the hopper at a rate approximating the rated capacity of the granulator. Feed rates in

excess of rated capacity will cause the machine to stall or jam.

SHUT DOWN THE MACHINE

To shut down, stop feeding the material into the hopper, and allow the machine to

run long enough to clear all material from the cutting chamber and discharge chute.

Press the stop pushbutton on the electrical cabinet. This shuts off the drive motor.

Turn off the power at the electrical cabinet.

Do NOT reach into the discharge cleanout opening with any part of your body. Movement

of the screen cradle at such a time could result in serious injury.

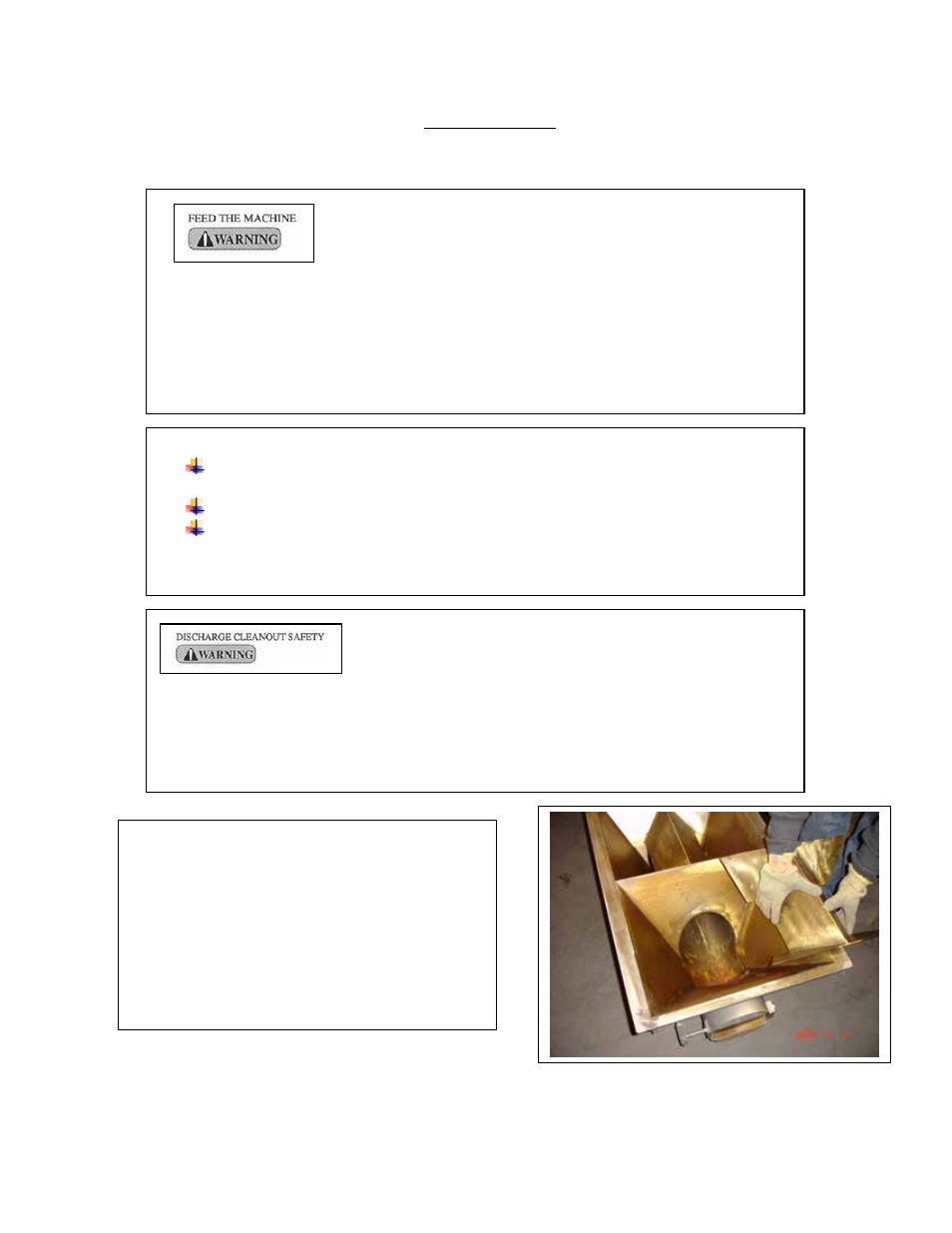

CLEANING THE DISCHARGE TRANSITION

When the front door is opened, any material

remaining in the discharge transition may be

removed via the discharge bin. If less pressure is

desired the dampers can be removed as shown.