Troubleshooting – Sterlco ST500 Series Central Granulator User Manual

Page 80

80

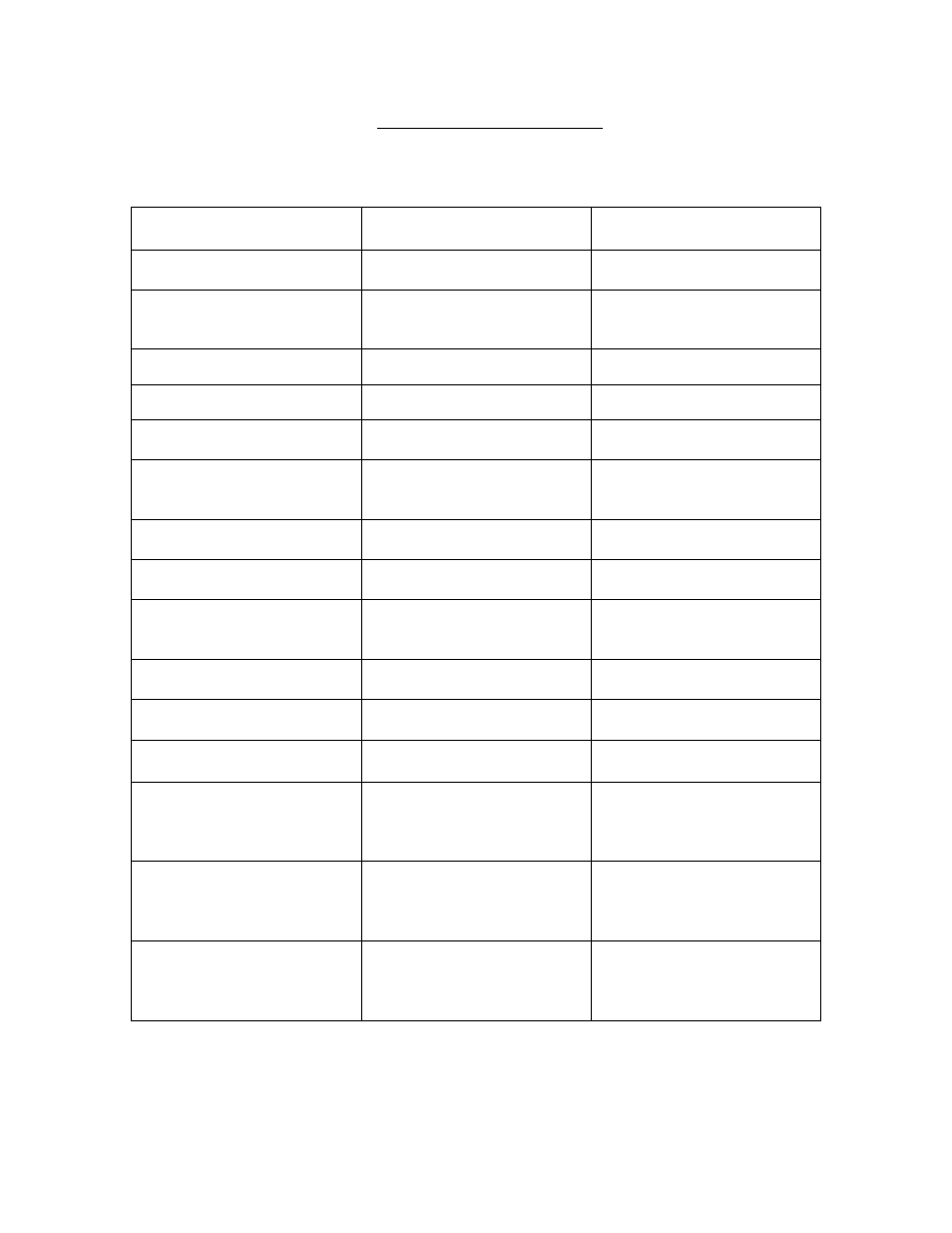

TROUBLESHOOTING

SECTION 7-2

Processing Faults

PROBLEM

Processing Faults

PROBABLE CAUSE

REMEDY

A. Material building up below

screen

1. Pneumatic discharge blower

not running

1. Start the blower

2. Damper on discharge

blower not open enough

2. Adjust the damper (on

opposite side of machine from

blower)

3. Damper line is blocked

3. Open line and remove block

B. Stalling

1. Overfeeding

1. Reduce feed rate

2. Partial or complete screen

blockage

2. Remove screen, clear and

inspect for damage

3. Insufficient tension on V-

belt drive, slippage and

burning

3. Check belt tension and

adjust as required

4. Badly blunted or damaged

knives

4. Install re-sharpened or new

knives as required

5. Knife gap setting is too

wide

5. Check knife gap clearances

6. Installation fault, motor is

running in reverse direction

6. Check direction arrow and

reset electrical connections to

correct rotational direction

7. Safety interlock is

inoperative

7. Tighten safety interlock

actuator screw

C. Material overheating

1. Check items 1, 2, 4, 5 and 6

under “Stalling”

1. Follow remedies listed for

each item

2. Screen size is too small

2. Increase the screen size

3. When feeding the material,

bed knife shield on rotor down

stroke is incorrectly set

3. Check bed knife projection

beyond shield. Set it to 1-2”

(0.80 mm) for film and 1/16”

(1.6 mm) or thicker materials

4. When granulating rubber,

insufficient talc, causing

freshly cut surfaces to re-

adhere

4. Increase talc percentage rate

of feed

5. Blockage in pneumatic

discharge line

5. Check direction of blower

rotation. Check venturi and

line/or transition piece for

blockage