Sterlco S-150 Digital Dosing Controller User Manual

Page 28

Digital Dosing Units

28

Operation - Injection Molding

1. Ensure that the unit is properly installed (Section 3.1), a recipe is entered

(section 3.3.1), and the feeder is calibrated (Section 3.6), before attempting to

begin operation.

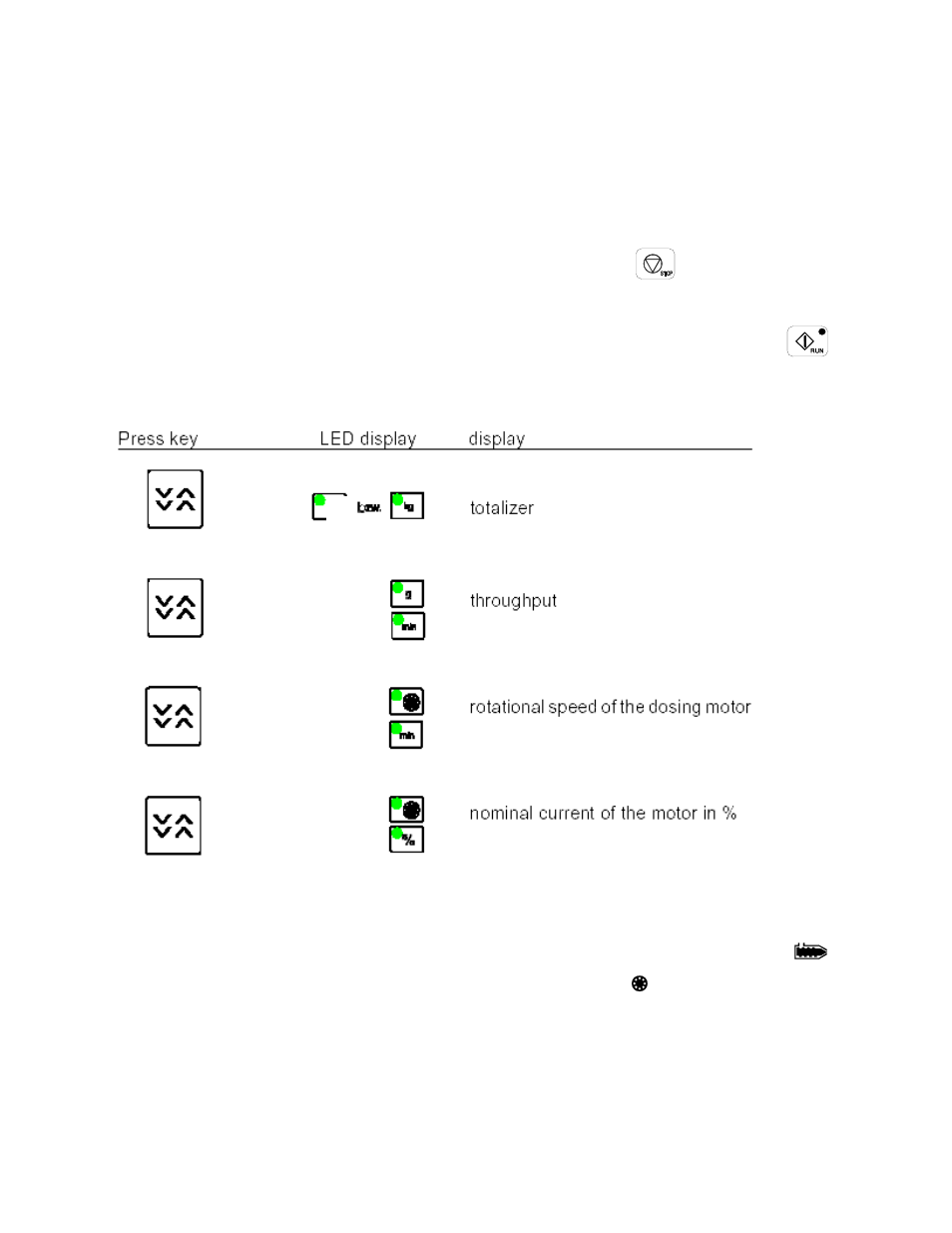

2. If desired, clear the totalizer by holding the Stop key (

) continuously for five

seconds until the display is reset to “00.00.”

3. Place the Digital Dosing feeder into operation by pressing the Run key (

).

The green LED will light when the unit is ready to dose.

Start the molding machine. The Digital Dosing feeder will not dose material until the molding

machine screw recovers. If the unit is installed properly, the process machine symbol

will light on the controller during screw recovery. The disc symbol will light when the Digital

Dosing unit is dosing material.

• The totalizer will increase after each cycle by the amount of material dosed.

or

- MDB Series Dryers (63 pages)

- SDA Series Medium Capacity Dehumidifying Dryer (52 pages)

- SDAP 90-225 CFM Series Drying and Conveying Systems (73 pages)

- SHA Series Hot Air Dryer (17 pages)

- SSL and SSIL Series Hopper Loaders (69 pages)

- SPL Series Powder Hopper Loader (43 pages)

- SVL Series Compressed Air Loaders (49 pages)

- SPV Remote Proportioning Devices (28 pages)

- SSC Conveying Systems (39 pages)

- SGBD Series Batch Gravimetric Blenders (101 pages)

- SGBD Series Batch Gravimetric Blenders (116 pages)

- SGBD Series Batch Gravimetric Blenders (110 pages)

- SDD Series (93 pages)

- SDD Series (96 pages)

- SF Series Volumetric Additive Feeder (55 pages)

- SF1000 Gravimetric Additive Feeder (37 pages)

- GH-F Series Gravimetric Additive Feeder (60 pages)

- GH Series Extrusion Control Weigh Hoppers (60 pages)

- A3 Blender Control and Data Acquisition Software (126 pages)

- SIT Inventory Monitor Units (18 pages)

- Micro Series Water Temperature Control Unit (45 pages)

- Micro Series Water Temperature Control Unit (46 pages)

- Royal Series Upright Temperature Control Unit (49 pages)

- SEU Series Economical Water TCU (42 pages)

- SEU Series Economical Water TCU (46 pages)

- 2016C (Former Compact Series) (61 pages)

- Midsize (59 pages)

- Upright High Temperature Heat Transfer (49 pages)

- GP Series 5-15 HP Portable Chillers (93 pages)

- GP Series 20-60 HP Packaged Chillers (93 pages)

- SMC 2-3.5 Portable Chillers (46 pages)

- SBFC Series Blown Film Coolers (34 pages)

- M2B+ Controller (68 pages)

- 140 to 6,285 Gallon Pump Tanks (36 pages)

- 140 to 6,285 Gallon Pump Tanks (67 pages)

- SF Series Cooling Towers (25 pages)

- GC Series Central Chiller (79 pages)

- 30RA Outdoor Air Cooled Central Chillers 10-60 Tons (28 pages)

- S Series Central Chilling Stations (86 pages)

- S Series Central Chilling Stations (77 pages)

- 4300 Series Stainless Steel Condensate Pumps (10 pages)