Hazard intensity level, Starting, Shutdown and daily maintenance starting – Prochem Everest EFI User Manual

Page 9

HAZARD INTENSITY LEVEL

EVEREST EFI 980197 08/16/04

2-3

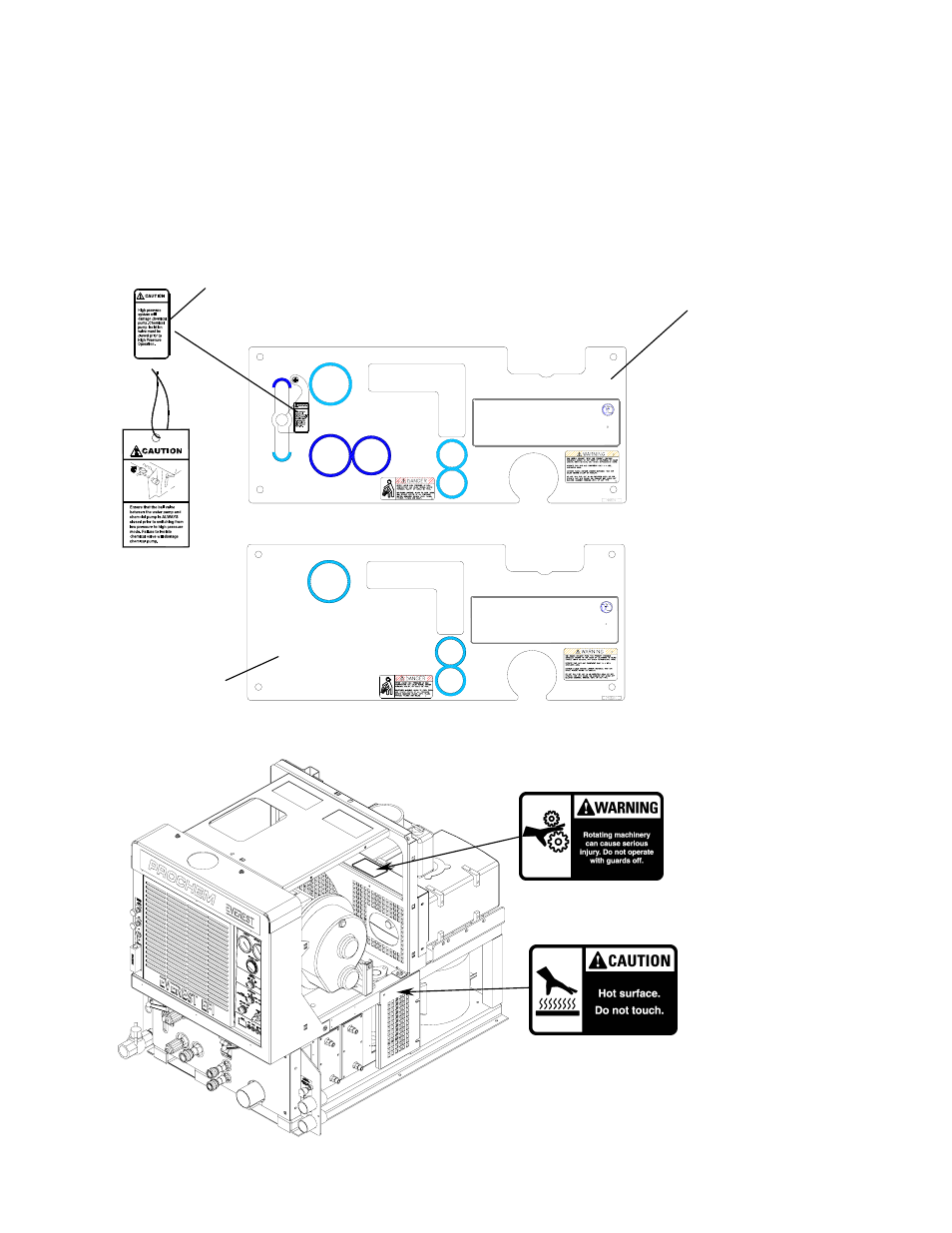

The following WARNING LABELS are found on your cleaning unit . These labels point out

important Warnings and Cautions which should be followed at all times. Failure to follow

warnings and cautions could result in fatality, personal injury to yourself and/or others, or

property damage. Follow these instructions carefully! DO NOT remove these labels.

NOTE: If at any time the labels become illegible, promptly replace them.

HOT

WARM

SOLUTION TEMPERATURE

CONTROL VALVE

STARTING

HIGH PRESSURE

SOLUTION OUTLET

LOW PRESSURE

SOLUTION SCREEN

CHEMICAL

CHECK VALVE

TEMPERATURE

BALANCE ORIFICE

CONDENSED OPERATING INSTRUCTIONS

1. CONNECT WATER HOSES TO WATER INLET CONNECTIONS AND TURN ON WATER SUPPLY.

2. CONNECT CLEANING AND VACUUM HOSES TO THE DESIRED CLEANING TOOL AND CONSOLE.

3. SET ENGINE SPEED CONTROL SWITCH TO IDLE AND TURN IGNITION KEY TO START.

4. SET ENGINE SPEED CONTROL SWITCH TO LOW/UPHOLSTERY POSITION.

5. INSERT CHEMICAL INLET AND PRIME TUBING INTO CHEMICAL CONTAINER.

6. TURN CHEMICAL PRIME VALVE TO PRIME AND ALLOW CHEMICAL TO CIRCULATE. AFTER ALL AIR BUBBLES HAVE BEEN REMOVED FROM THE CHEMICAL

TUBING, TURN THE VALVE TO THE OFF POSITION, OPEN THE CHEMICAL FLOW AND FLOW SIMULATOR VALVES. SET THE DESIRED CHEMICAL FLOW RATE WHILE

OBSERVING THE FLOW METER INDICATOR. FLOW SIMULATOR VALVE MUST BE IN THE OPEN POSITION TO SET CHEMICAL FLOW. WHEN DESIRED FLOW IS

REACHED, TURN FLOW SIMULATOR VALVE OFF.

7. FOR QUICK HEAT-UP, REFER TO OPERATING INSTRUCTIONS.

1. CLOSE CHEMICAL METERING VALVE.

2. ALLOW THE UNIT TO RUN FOR 2 MINUTES WITH THE VACUUM HOSE DISCONNECTED TO REMOVE MOISTURE AND SPRAY WD40 (OR EQUIVALENT) INTO

THE VACUUM LUBRICATION CUP. THIS WILL PREVENT CORROSION DUE TO MOISTURE.

3. SET ENGINE SPEED CONTROL SWITCH TO IDLE POSITION AND OPEN FLOW SIMULATOR VALVE, ALLOWING THE WATER TEMPERATURE TO COOL DOWN.

4. TURN OFF IGNITION SWITCH.

5. DISCONNECT ALL HOSES AND TOOLS.

6. DRAIN WASTE TANK INTO AN APPROVED SOURCE.

SHUTDOWN AND DAILY MAINTENANCE

SOLUTION

PRESSURE

HIGH PRESSURE

1000-3000 PSI

HIGH PRESSURE

SOLUTION REGULATOR

LOW PRESSURE

SOLUTION REGULATOR

LOW PRESSURE

50-1000 PSI

LOW PRESSURE

SOLUTION OUTLETS

CARPET AND

UPHOLSTERY

SOLUTION

Caution Tag

Part # 500706

Front panel decal-PP

Part # 790820

Caution label

Part # 500707

Front panel decal-PPHP

Part # 790819

Caution label

Part # 500770

Warning label

Part # 500769

SOLUTION TEMPERATURE

CONTROL VALVE

CONDENSED OPERATING INSTRUCTIONS

1. CONNECT WATER HOSES TO WATER INLET CONNECTIONS AND TURN ON WATER SUPPLY.

2. CONNECT CLEANING AND VACUUM HOSES TO THE DESIRED CLEANING TOOL AND CONSOLE.

3. SET ENGINE SPEED CONTROL SWITCH TO IDLE AND TURN IGNITION KEY TO START.

4. SET ENGINE SPEED CONTROL SWITCH TO LOW/UPHOLSTERY POSITION.

5. INSERT CHEMICAL INLET AND PRIME TUBING INTO CHEMICAL CONTAINER.

6. TURN CHEMICAL PRIME VALVE TO PRIME AND ALLOW CHEMICAL TO CIRCULATE. AFTER ALL AIR BUBBLES HAVE BEEN REMOVED FROM THE CHEMICAL

TUBING, TURN THE VALVE TO THE OFF POSITION, OPEN THE CHEMICAL FLOW AND FLOW SIMULATOR VALVES. SET THE DESIRED CHEMICAL FLOW RATE WHILE

OBSERVING THE FLOW METER INDICATOR. FLOW SIMULATOR VALVE MUST BE IN THE OPEN POSITION TO SET CHEMICAL FLOW. WHEN DESIRED FLOW IS

REACHED, TURN FLOW SIMULATOR VALVE OFF.

7. FOR QUICK HEAT-UP, REFER TO OPERATING INSTRUCTIONS.

1. CLOSE CHEMICAL METERING VALVE.

2. ALLOW THE UNIT TO RUN FOR 2 MINUTES WITH THE VACUUM HOSE DISCONNECTED TO REMOVE MOISTURE AND SPRAY WD40 (OR EQUIVALENT) INTO

THE VACUUM LUBRICATION CUP. THIS WILL PREVENT CORROSION DUE TO MOISTURE.

3. SET ENGINE SPEED CONTROL SWITCH TO IDLE POSITION AND OPEN FLOW SIMULATOR VALVE, ALLOWING THE WATER TEMPERATURE TO COOL DOWN.

4. TURN OFF IGNITION SWITCH.

5. DISCONNECT ALL HOSES AND TOOLS.

6. DRAIN WASTE TANK INTO AN APPROVED DISCHARGE POINT.

SOLUTION OUTLETS

CARPET AND

UPHOLSTERY

SOLUTION

SOLUTION SCREEN

SHUTDOWN AND DAILY MAINTENANCE

STARTING

SOLUTION PRESSURE

REGULATOR

CHEMICAL

CHECK VALVE

TEMPERATURE

BALANCE ORIFICE

WARM

HOT