Dwyer ULSS User Manual

Page 23

Rev 5

MN890570

23 of 30

INSTALLATION

Step Nine

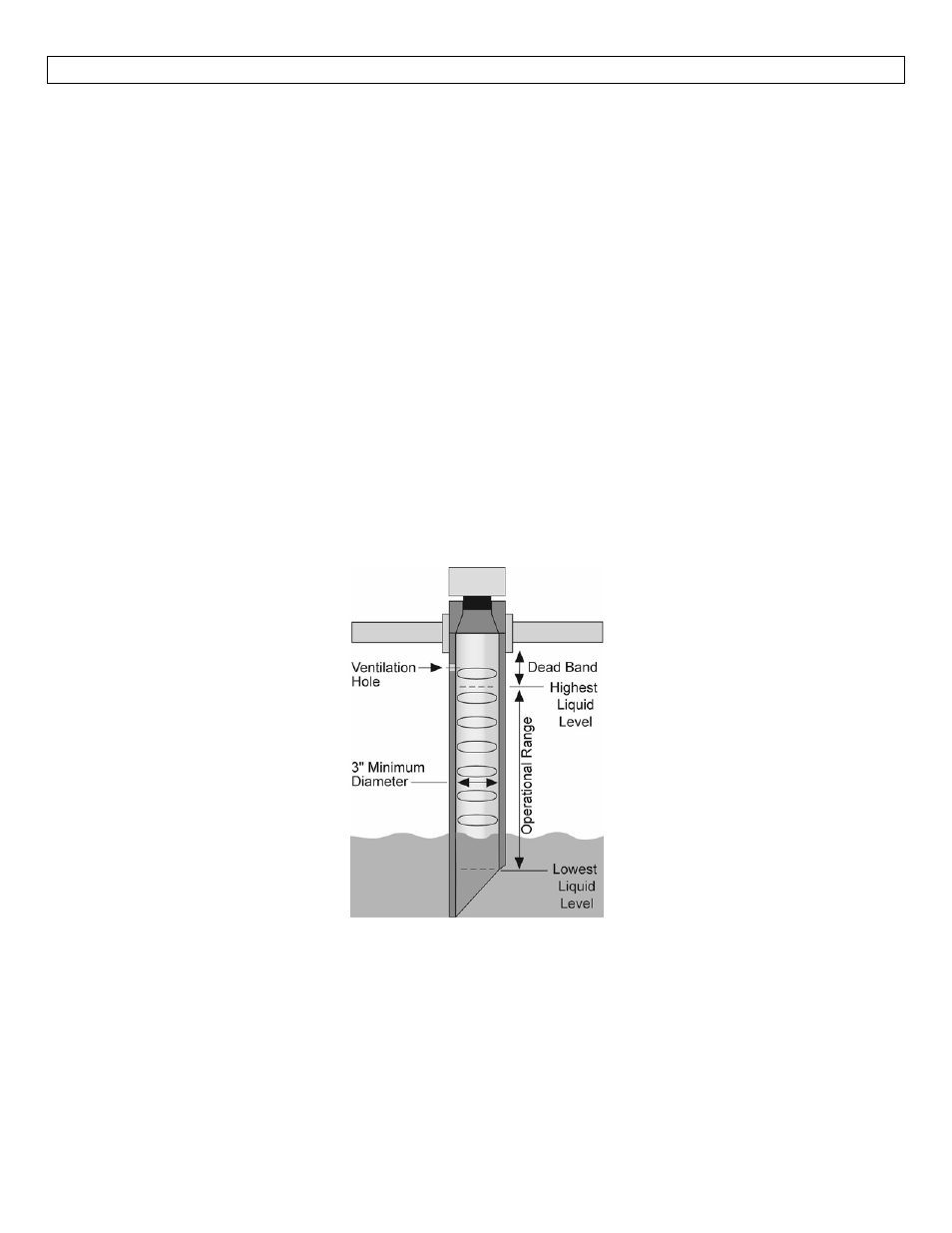

5. Stand Pipe: A standpipe maybe used to dampen turbulence or when foam is present in the

application.

a. Pipe can be made of any material.

b. Select a minimum 3” ID pipe for the stand pipe.

i. A 2” pipe is usable with the Series ULSS & ULSM, but is the minimum.

ii. Pipes larger than 3” can also be used.

c. Use a coupling and reducer bushing to attach the Series ULS to the pipe.

i. Be sure to use a plastic reducing bushing such as ULS‐ACC‐121 (2” T x 1” T) fitting or the

ULS‐ACC‐221 (2” S x 1” T) fitting.

ii. For the Series ULSL, use a reducer bushing such as ULS‐ACC‐131 (3” T x 2” T) fitting or

the ULS‐ACC‐231 (3” S x 2” T) fitting.

d. The pipe length should run the measurement span and the bottom of the pipe should remain

submerged at all times to prevent foam from entering the pipe.

e. Cut a 45° notch at the bottom of the pipe and drill a 1/4”pressure equalization hole in the dead

band.

f. The pumps should not drive liquid past the open end of the stand pipe which causes the liquid

in the pipe to oscillate.