Caleffi 6000 User Manual

Page 44

19

Relay

contact

for

recirculation

pump

and

second

storage thermostat

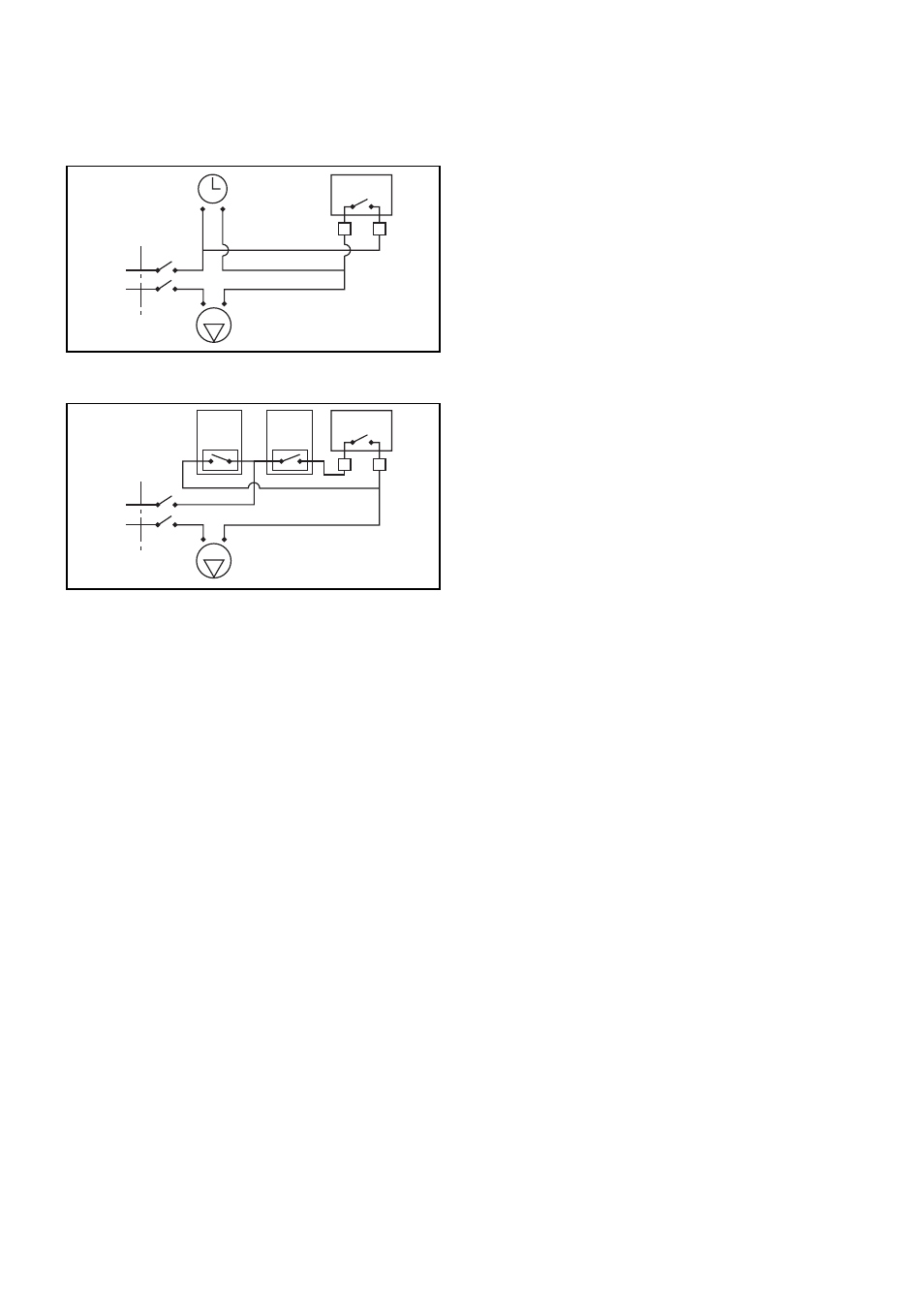

Here following the wiring diagram of relay 1 with a clock for

managing the recirculation pump times.

Here following the wiring diagram of relay 3 for connection to the

second thermostat on the hot water storage.

Maintenance

Tests are carried out while in service, to regularly monitor the

performance of the mixing valve, since any loss of performance

may indicate the need for maintenance of the valve and/or the

system. During these tests, if the temperature of the mixed water is

found to have changed significantly compared with previous tests,

we recommend referring to the sections on installation and

commissioning and carrying out maintenance.

We recommend carrying out the following checks periodically to

ensure that the valve continues to keep optimum performance

levels. At least every 12 months, or more frequently if required.

1) Check and clean the strainers installed in the system

2) Check that any check valve installed at the inlet of the Caleffi

valve is functioning correctly and there is no seepage caused by

dirt.

3) The internal components of the valve can be descaled by

immersing them in a suitable descaling liquid.

This operation is essential in the case of systems that are used

seasonally, for example in hotels and similar establishments.

4) Once the maintainable components have been checked, we

recommend following the commissioning procedure again.

On the system log book, record all operations carried out.

Functional faults

A special set of alarms has been provided to help managing

possible faults that can occur in the regulator and the system.

Please refer to the “Alarms Management” section below.

L

N

Recirculation pump

Relay 1

1

2

L

N

Storage primary pump

Relay 3

T1

60°C

T2

70°C

5

6