11 examples for self-tuning attempts 23, Operation – West Control Solutions Pro-4 User Manual

Page 23

3.5.11 Examples for self-tuning attempts

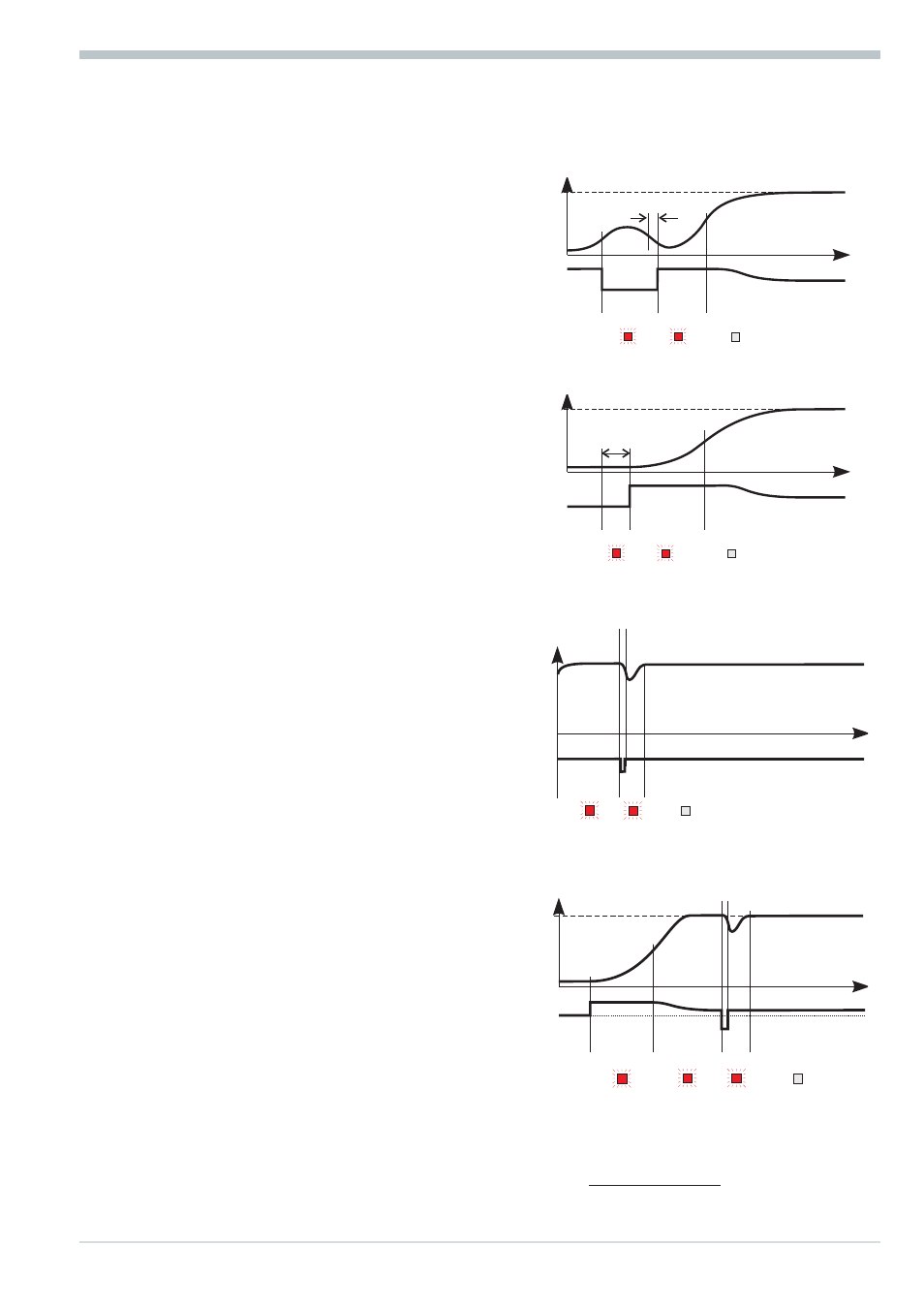

(controller inverse, heating or heating/cooling)

Start: heating power switched on

Heating power Y is switched off (1).

When the change of process value X

was constant during one minute (2),

the power is switched on (3).

At the reversal point, the self-tuning at-

tempt is finished and the new parameter

are used for controlling to set-point W.

Start: heating power switched off

The controller waits 1,5 minutes (1).

Heating power Y is switched on (2).

At the reversal point, the self-tuning

attempt is finished and control to the

set-point is using the new parameters.

Self-tuning at the set-point a

The process is controlled to the

set-point. With the control deviation

constant during a defined time (1)

(i.e. constant separation of process value

and set-point), the controller outputs a

reduced correcting variable pulse (max.

20%) (2). After determination of the

control parameters using the process

characteristic (3), control is started

using the new parameters (4).

Three-point controller a

The parameter for heating and cooling are

determined in two attempts. The heating

power is switched on (1). Heating para-

meters Pb1, ti1, td1 and t1 are de-

termined at the reversal point. Control to

the set-point occurs(2). With constant

control deviation, the controller provides a

cooling correcting variable pulse (3). Af-

ter determining its cooling parameters

Pb2, ti2, td2 and t2 (4) from the

process characteristics , control operation is started using the new parameters (5).

a

During phase 3, heating and cooling are done simultaneously!

Operation

KS 90-1 / KS 92-1

23

Self-tuning

t

+100%

Y 0%

-100%

X

W

t reversal

point

Start r

1

2

3

4

5

r t

t

2

100%

Y

0%

X

W

1

3

blinks

4

r t

Start r

t

2

100%

Y

0%

X

W

Start r

1

3

t reversal point

blinks

t

100%

Y

0%

X

W

start r

1

2

t reversal point

blinks