Fault chart, Operation – KROHNE OPTISYS TUR 1050 EN User Manual

Page 49

OPERATION

5

49

OPTISYS TUR 1050

www.krohne.com

11/2012 - 4002444301 MA OPTISYS TUR 1050 R02 en

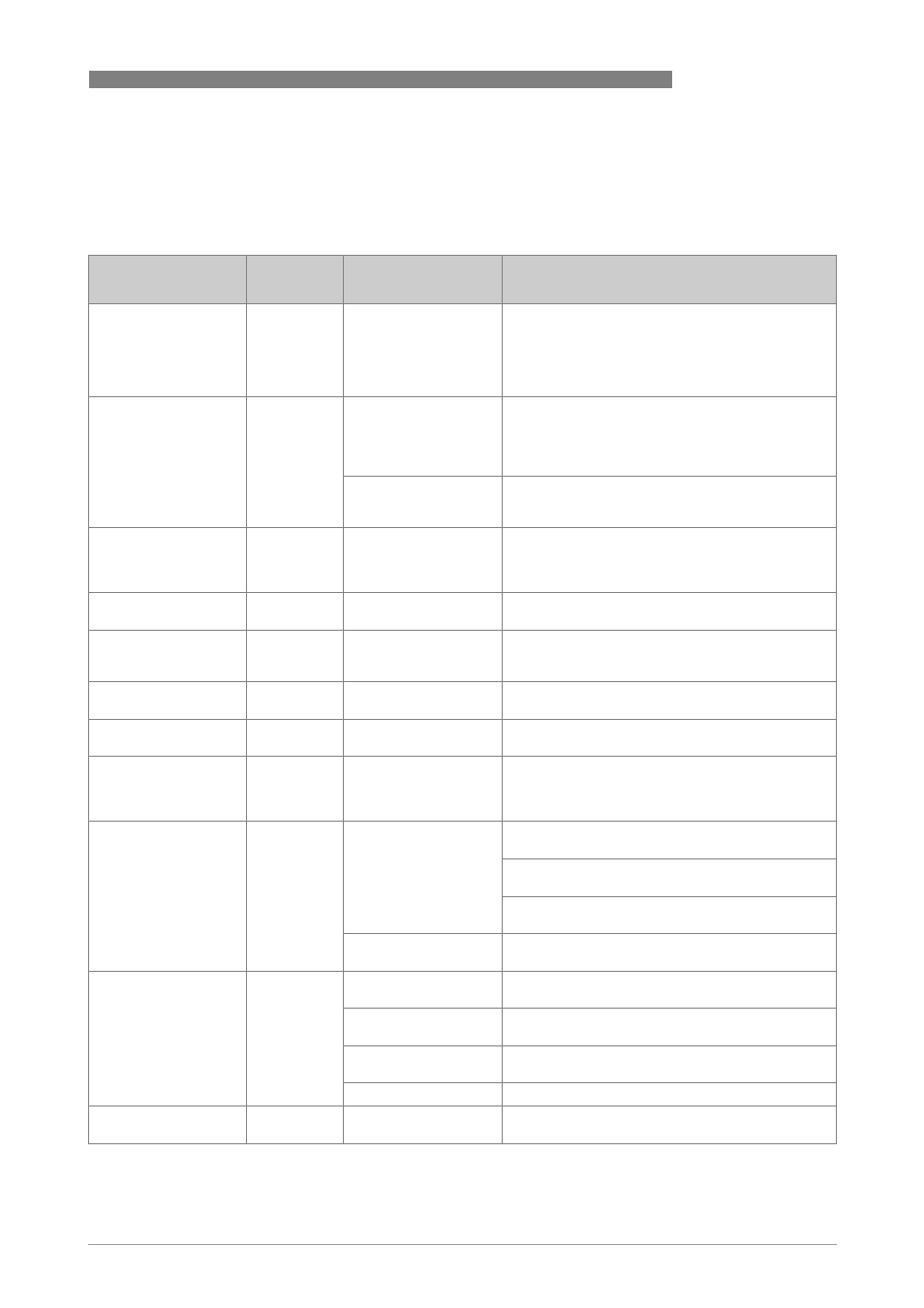

Apart from the faults shown before there are problems that do not have a specific message in

the display (e.g. extremely alternating measuring results). The following table contains both

kinds of problems:

Fault chart

Fault message /

problem

Category

Cause

Measurement

CAL (bottom row of

display)

Error

Deficient calibration or

calibration impossible.

Ensure that you use a proper calibration liquid (the

best way is to use the calibration cuvettes of the

manufacturer); if the calibration fails nonetheless,

check the output of the sensor lamp and clean it or

replace. After you remedied the problem, you have

to recalibrate the device.

CLN (bottom row of

display)

Error

Ultrasonic transducer

has no contact to the

spring connections or

transducer itself is

damaged.

Rotate ultrasonic cuvette slightly to improve the

spring connection; if message persists, the

transducer itself is damaged and you have to

replace the whole cuvette.

Ultrasonic cuvette has

been removed or

wrong cuvette is used.

Insert correct ultrasonic cuvette and pay attention

to the correct procedure (details on page 21).

DESC (bottom row of

display, only if

desiccant alarm

disabled)

Warning

Desiccant in the pouch

is saturated or bad.

Change desiccant pouch (details on page 51).

FAIL (bottom row of

display)

Failure

Complete malfunction

of an internal system.

Return the device to the manufacturer.

FLOW (bottom row of

display, only if flow

switch is installed)

Error

Sample flow stopped.

Restore sample flow, contact manufacturer for

further information.

LAMP (bottom row of

display)

Error

Light source fails.

A service employee of the manufacturer has to

replace the lamp, do not do it on your own!

MA (bottom row of

display)

Error

4...20 mA loop open.

Check wiring of the current output (details on page

Measuring result

blinks (i.e. value in the

upper row of the

display)

-

Exceeding of

measuring range, i.e.

turbidity is too high.

Take a sample and check the turbidity in a

laboratory.

Measuring result

alternates extremely

-

Bubbles in the

measured medium.

Ensure that the drain vent hole is open and not

blocked.

Apply backpressure with the help of the

backpressure valve.

In case of severe bubble formation use a stilling

chamber (available as accessory part).

Debris in the ultrasonic

cuvette.

Remove cuvette (details on page 50) and clean it

with a soft cloth.

Measuring result is

higher than expected

-

Bubbles in the

measured medium.

See above in this table.

Condensate or dirt in

the ultrasonic cuvette

Remove cuvette (details on page 50) and clean it

with a soft cloth.

Leaky ultrasonic

cuvette.

Check for leakages and replace devices if

necessary.

Improper calibration.

Recalibrate the device (details on page 30).

Measuring result is

lower than expected

-

Improper calibration.

Recalibrate the device (details on page 30).