Quick start – DeFelsko PosiTector 100 v.4.0 User Manual

Page 7

100 Series

Page 7

The Model 100 hand-held, electronic Gage uses an ultrasonic technique to non-

destructively measure the thickness of coatings on various substrates quickly

and accurately. The probe emits an ultrasonic pulse into the coating. Reflections

from the coating/substrate interface, coating/coating interfaces and other

conditions are picked up by the probe. The travel time is converted into a

thickness value shown on the display. Power is supplied from either two “C”

size Alkaline-Manganese Dioxide batteries or an external power supply.

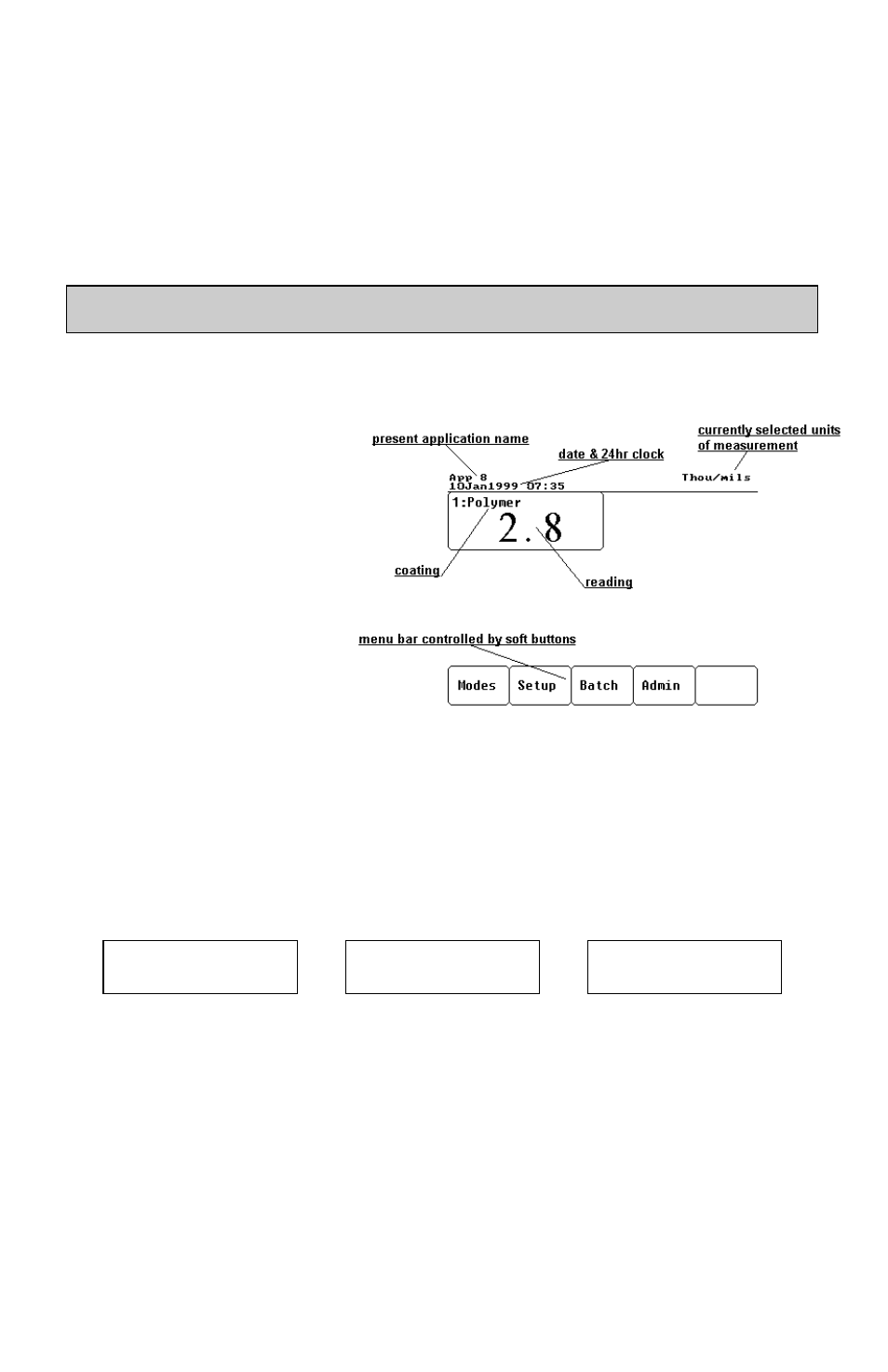

Quick Start

The Model 100 is always ready to measure. Here are some quick tips:

q

Read “How to Take a Measurement” on page 18 to familiarize yourself

with basic Gage

operation.

q

Practice measuring the

included plastic shims

as described on page

28 to confirm the Gage

is operating properly

and that the operator is

using it properly.

q

If you have a sample of

your coating with a

known thickness, you

may want to adjust the

Gage to this material.

Read “Calibration and Adjustment” on page 24 to

how to make the Gage adjustments before taking your measurements.

q

Select the

Setup Application Setup menu item and adjust values

as necessary (pg.19) for your coating.

q

Measure your application.

Remember the “golden rule”:

Calibrate

see pg.24

⇒

Optimize

see pg.26

⇒

Measure

see pg.18