Theory of operation – DeFelsko PosiTector 100 v.4.0 User Manual

Page 16

Page 16

100 Series

A visual inspection, such as that obtained by microscopically viewing a cross-

sectional cut of the material, often reveals useful information about your

application. It may also explain why the Gage behaves the way it does when

measuring your part.

Finally, you are always welcome to contact us at

with

your inquiries. Be sure to include as much information about your application

and about the results obtained from known samples such as the plastic shims as

well as from the unknown material you are trying to measure. Provide us with

the Gage serial number and details about the material you are measuring and the

size and shape of the part. If all else fails you are welcome to send us a sample

of your application for measurement by our lab technicians.

Theory of Operation

The Model 100 uses an ultrasonic pulse echo principle. By transmitting an

ultrasonic pulse into the coating/substrate specimen and determining the time

taken for the pulse to travel to the coating/substrate interface and back to the

transducer, a coating thickness can be calculated.

The Gage transmits a high frequency, ultrasonic vibration into the coating using

a single element transducer. The vibration travels through the coating material

until a material with different mechanical properties is encountered, typically the

substrate. The vibration will be partially reflected and transmitted at the

interface between the dissimilar materials. The reflection will propagate back

through the coating and will be detected by the transducer. The transmitted

vibration will continue to travel into the substrate material and will also

experience reflections and transmissions at any material interfaces that are

encountered.

The transducer converts the reflections into an electrical signal which the Gage

digitizes. The digitized echo wave form is then analyzed to determine the exact

propagation time of the vibration.

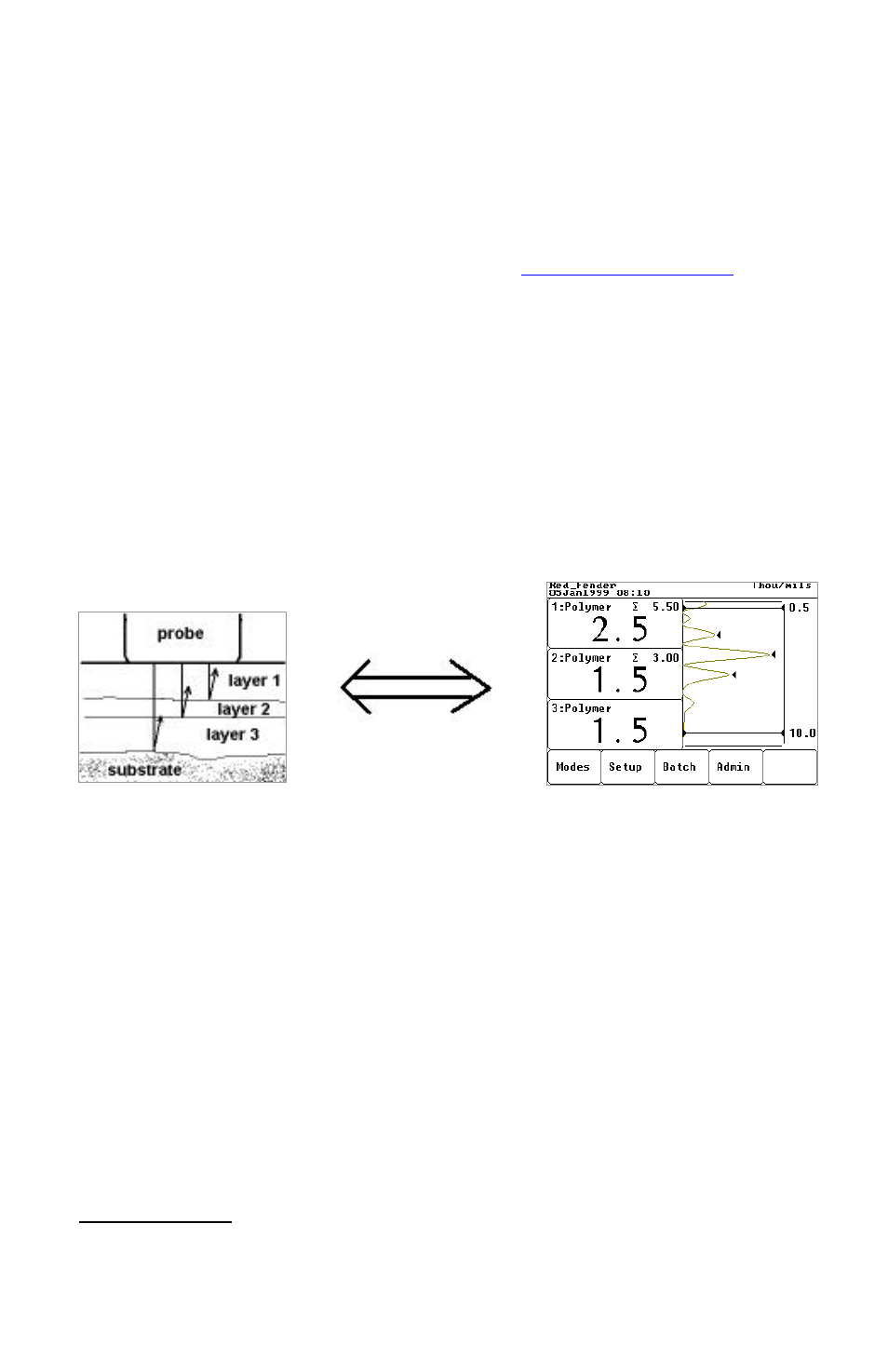

Layer 1 is 2.5 mils thick. Layer 2 is 1.5 mils thick.

Layer 3 is 1.5 mils thick. Total thickness is 5.5 mils.

The most distinct interface is between layers 2 & 3.