Optimization – DeFelsko PosiTector 100 v.4.0 User Manual

Page 26

Page 26

100 Series

C

ALIBRATION

I

NTERVAL

Start with a recommended interval of one year and adjust that interval according

to your individual usage and environment.

Optimization

Thickness measurement error is minimized by ensuring that the Gage has the

correct velocity value for the particular coating system being measured. This is

done by following a 2-step procedure:

1. S

ELECT A

C

ATEGORY

2. O

PTIMIZE TO A

K

NOWN

T

HICKNESS

Since actual sound velocity in materials often varies significantly from the

values found in published tables, optimization of the Model 100 for velocity is

made by measuring a known thickness of the particular material being measured

and adjusting the displayed result to the actual, known thickness. If a known

thickness is not available, factory settings alone can be used.

The need to optimize is dependant upon a number of factors, not the least of

which is the level of accuracy required. To measure thin coatings for which a

high degree of accuracy is required, such as lacquer on wood with a B probe, for

example, the user may decide that optimization is needed. To measure thick,

rough coatings for which fine accuracy is not critical such as epoxy on concrete

with a C probe, the user may decide that only Step 1 (selection of a category) is

needed. To measure paint on plastic with a B probe and have traceability to a

standard, Steps 1 and 2 must both be performed.

When an adjustment is made to the sound velocity constant, the upper and lower

measuring limits of the probe change. A fast velocity value, such as for metal,

raises both the thinnest and thickest measuring limits of the probe. A slower

velocity value, such as for rubber, lowers both the thinnest and thickest

measuring limits of the probe. Table 4 on page 41 gives some examples.

S

TEP

1: S

ELECT A

“C

ATEGORY

”

Probes for the Model 100 come pre-adjusted for a variety of coating and

substrate types, or categories.

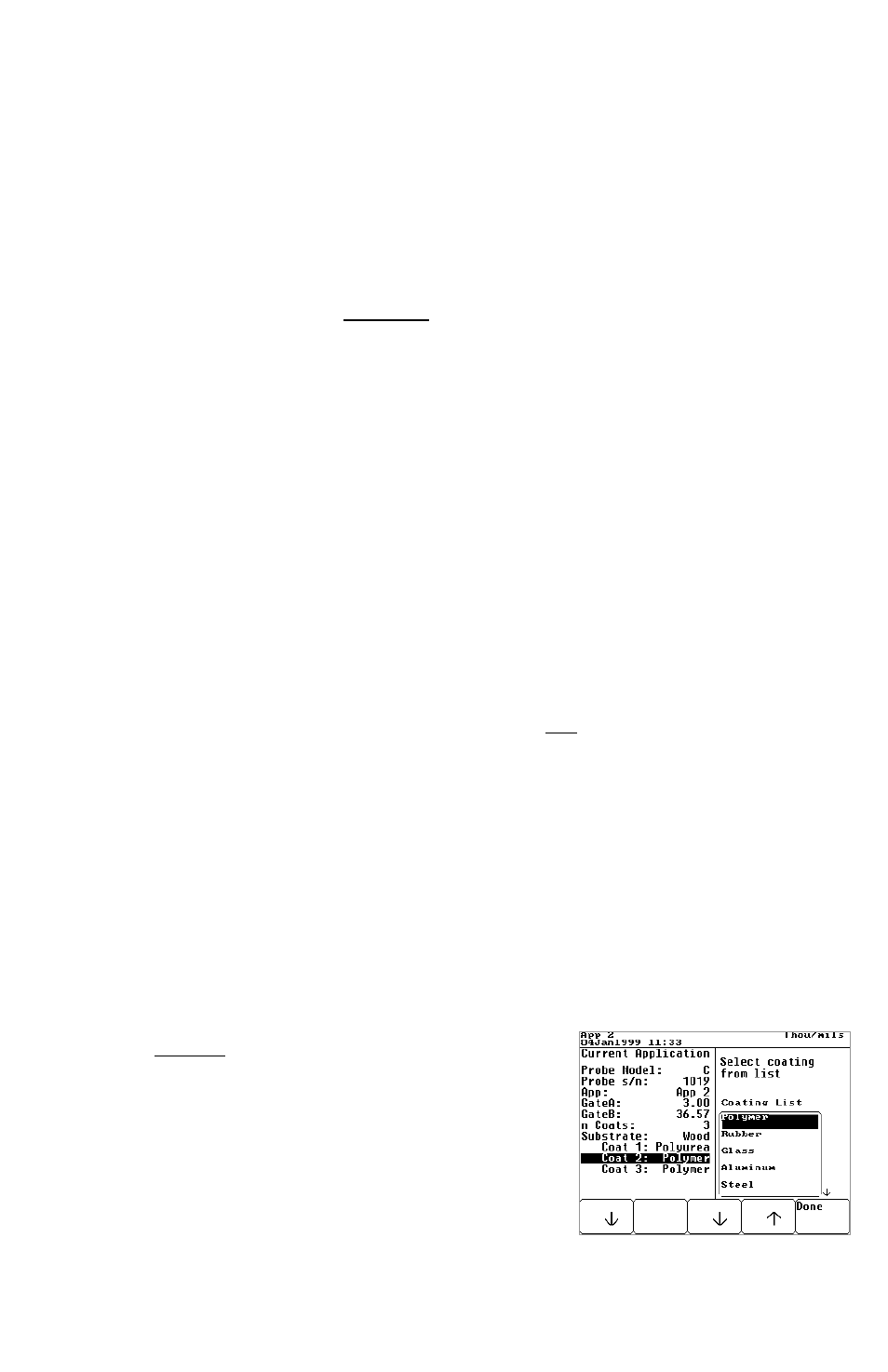

When a coating category is selected from the Coating

List, a typical sound velocity constant for that

material is used by the Gage. The number of coating

categories available to choose from depends upon the

type of probe that is attached. B probes have only one

category, polymer. The C and D probes have several

categories including polymer, rubber, glass and

metal.