Specifications, Service, Astm – DeFelsko PosiTector 100 v.4.0 User Manual

Page 39: Temperature

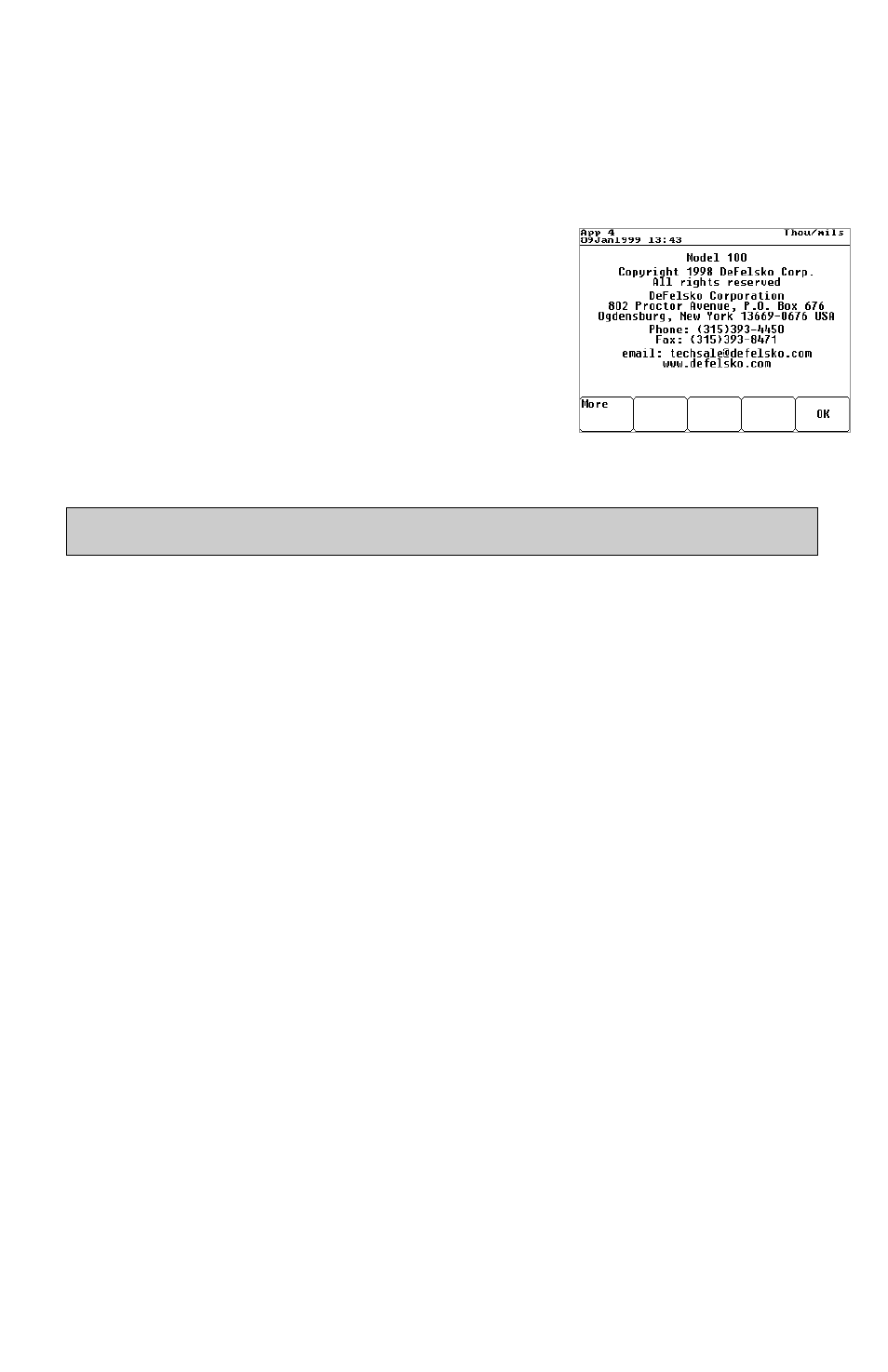

100 Series

Page 39

Service

Before returning the Gage for service, attempt to clear the problem by…

•

installing new, “C” alkaline batteries (pg.37), and

•

performing a RESET (pg.30), and if still necessary

•

performing a Gage INITIALIZATION (pg.31)

to restore factory settings and to return the Gage

to an “out-of-the-box” condition.

For service, ensure the following:

•

return Gage, probe and all related material,

including samples if appropriate

•

include company name, return address, contact

and fax number

•

describe the problem as completely as possible

Specifications

Due to continuous process improvement, specifications are subject to change

without notice.

ASTM

The Model 100 conforms to ASTM D6132 – Standard Test Method for

Nondestructive Measurement of Dry Film Thickness of Applied Organic

Coatings Over Concrete Using an Ultrasonic Gage. The Scope of this Test

Method states, “This test method covers the use of ultrasonic film thickness

gages to measure accurately and nondestructively the dry film thickness of

organic coatings applied over a substrate of dissimilar material”. The Test

Method is available from ASTM in West Conshohocken, Pennsylvania, USA at

telephone number (610) 832-9500.

Temperature

Variations in temperature change the velocity of sound in materials, including

the probe. All optimization should be performed on-site with check standards at

the same temperature as the test piece in order to minimize errors due to

temperature variations.

The operating range for the Model 100 is

+

32 to

+

100F (0 to

+

40C). The Gage

compensates automatically for temperature within its operating range. “B”

probes also compensate automatically. “C” and “D” probes are not temperature

compensated and should be allowed a few minutes to reach ambient temperature

before measuring. These two probes should be ZEROED when temperature

changes are suspected (pg.29).