DeFelsko PosiTector 100 v.4.0 User Manual

Page 15

100 Series

Page 15

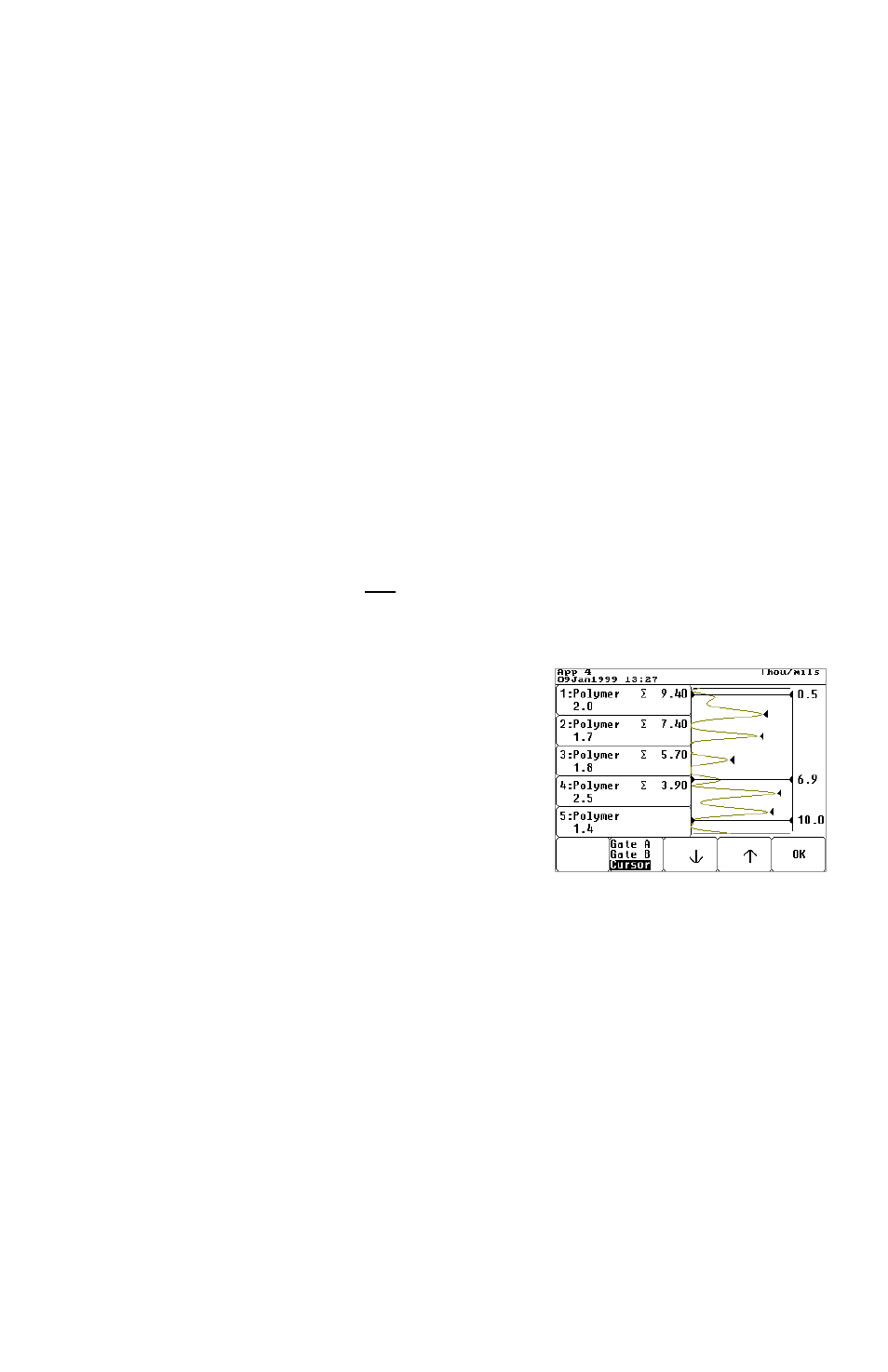

Gage is set to its maximum 5 coats. The

5 largest peaks are displayed on the

left. However a 6

th

layer interface exists

at 6.9 mils (from the surface) as

measured by the CURSOR.

Once you have checked Gage operation on a known thickness of material and

have modified current Application settings to most closely match your

coating/substrate combination you are ready to measure. Be sure to apply

sufficient couplant to fill voids in the surface and to fully wet the probe tip.

Multiple measurements in the same location may require additional couplant

every so often. Hold the probe steady when measuring and release the probe

switch after hearing the double BEEP. Leaving the Graphics Mode turned on

helps you to understand what the Gage sees and how it arrived at a thickness

measurement.

Never rely on a single measurement. It is important that several measurements

be consistent and repeatable, or as repeatable as your application will allow. If

the coating or substrate is rough or curved, use Statistics Mode to determine the

average of a series of readings. Comparing a series of averaged results will often

provide acceptable repeatability where individual readings might not.

Don’t be too quick to adjust a displayed reading to reflect what you believe the

coating thickness to be. Even though another measurement method might report

a different thickness, it is better to leave the Gage at its default settings and

evaluate repeatability first. The last step in any measurement application is

optimization using the

Setup q

q Adjust Reading / Adjust Velocity

menu option.

Whenever you run into difficulty, be sure to stop and

measure your Check standards, the plastic shims or

some other part you previously had success measuring.

Once you have made sure you are operating the Gage

correctly and that it is performing properly, return to

your application. Verify the settings found in

Setup

Application Setup. Then select Setup q

q

Gate/Zoom Control and, between

measurements, change Gate A and B values to observe

the reflected echoes. Use the cursor to measure peaks

not measured by the Gage (measured peaks have a

black triangle beside them).

To measure properly, the ultrasonic echo must pass completely through the coating(s),

reflect off an acoustically dissimilar material such as the substrate or other coatings, and then

return unimpeded to the probe tip. Sometimes the coating is not homogeneous; it contains

solids or uncured sections that dampen or deflect the echo. Sometimes the interface between

coatings and the substrate is not distinct; the two materials have blended to create a

“transition” layer. Also the material may either be too thin or acoustically too thick or

attenuative to measure with an ultrasonic technique.