8 troubleshooting loup iii system, Setting shank pressure – Seed Hawk AIRCART 2014 User Manual

Page 36

SEED HAWK

®

2014 AIRCART OPERATOR’S MANUAL

SEED HAWK

®

2014 AIRCART OPERATOR’S MANUAL

64

NOTE: The window item se-

lection is time limited. If no

action is taken after selecting

“Item” from the soft key

menu the monitor will cancel

the function.

NOTE: The correct item type

for this function is “Shank”.

There is also a selection

choice called “Pressure”. This

is reserved for an optional

pressure measurement sen-

sor for use with the MuxBus

sensor system.

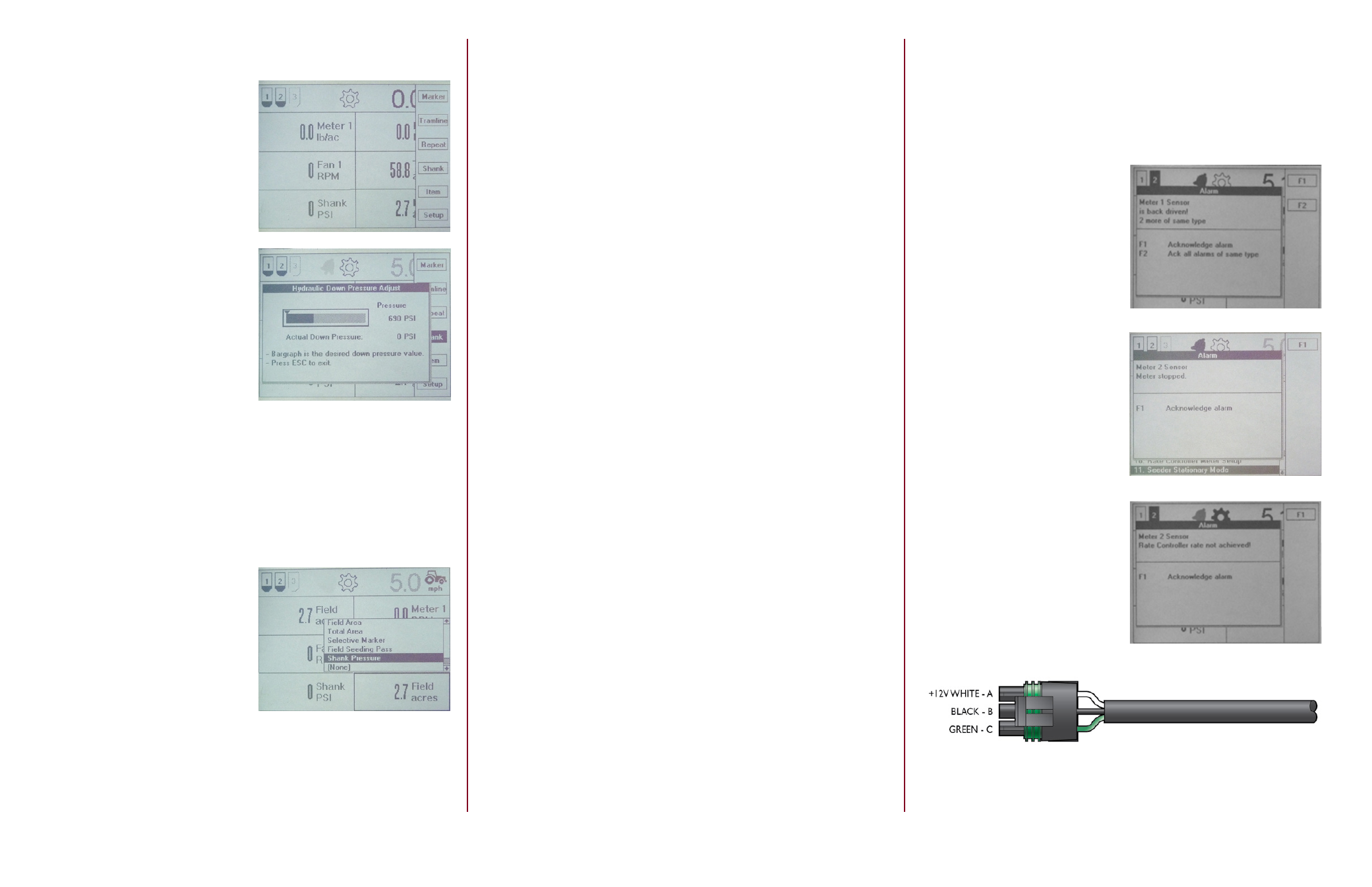

Setting Shank Pressure

2. A horizontal bar graph display will

come up on the screen. Press

Enter

to activate the adjustment and then

rotate the

Toggle Knob to increase

or decrease the system pressure

setting.

3. Press Enter again to save the setting. When seeding this screen will show the

system pressure setting and a triangular shaped icon will move up and down

the bar graph to show the measured system pressure as compared to the set

pressure.

The Operator can also view the actual system pressure while seeding by select-

ing it as a display item. The monitor will display the applied down pressure on

the run screen. Refer to Section 7.3.4 for more information.

To add this to the display press any

of the

Soft Keys to bring up the

soft key menu, then press “Item”. A

highlight box will appear over the

upper left hand window. Navigate the

highlight box to the display window

desired to display the shank down

pressure information and press

Enter. A menu will appear with a

list of all the items you can display in

the window. Navigate to “Shank” and

press

Enter.

1. Press any soft key to bring up the

soft key menu and press “Shank”.

65

7.8 Troubleshooting Loup III System

1. MUX Sensor is not recognized at power up. This will include the ground

speed, fan, and bin level sensors

Solution: With the system turned on,

go the sensor that is not communi-

cating. There is a LED on each sensor

(except the multilevel bin sensor). If

it is flashing slowly (1 flash every 2-3

seconds) that indicates that power

and ground are connected but the

sensor wire is not. The power wire is

+12 volts and is the white wire. It is

in the “A” position on the connector.

The Ground wire is black and is in the

“B” position on the connector. The

sensor wire is the green wire and is

in the “C” position on the connector.

If the LED is not flashing, unplug the

sensor from the harness and plug it

back in. If the LED lights momentarily,

power is present and the sensor is

faulty. If the LED does not light at all

check power at the connector. You

should measure 12 volts between

the white and black wire. If you do,

the sensor is faulty, if you don’t the

harness is faulty. All the white wires

on the MUX harness are connected

in parallel, all the black wires are in

parallel, and all the green wires are in

parallel. You can measure continuity

be- tween any of the “A”, “B”, or “C”

connections on the MUX harness.

Possible causes: Harness wiring is faulty or the sensor is defective.