3 piping, 1 sample liquid conduit, Sample liquid conduit -10 – Yokogawa DM8C/VD6 Liquid Density Analyzer User Manual

Page 36

< 3. INSTALLATION, PIPING AND WIRING >

3-10

IM 12T03A01-02E

3.3 Piping

The vibration type density meter requires the following piping;

(1) Sample liquid conduit

(2) Air piping for maintenance

(3) Steam

piping

(4) Piping for air purge

Sample liquid conduit is a pipe to conduct measuring liquid to the density detector. Air piping for

maintenance is to obtain air to blow away liquid from the vibrator at maintenance (vibrator cleaning,

calibration with standard solution). Steam piping which is installed according to requirement is to

obtain a steam to heat the sample liquid conduit. Air purge piping is necessary when the converter is

installed in dusty environment.

The sample liquid conduit referred here indicates pipes between the main process pipe and the

sampling equipment. For piping within the sampling equipment, refer to Section 3.1.2.

3.3.1 Sample Liquid Conduit

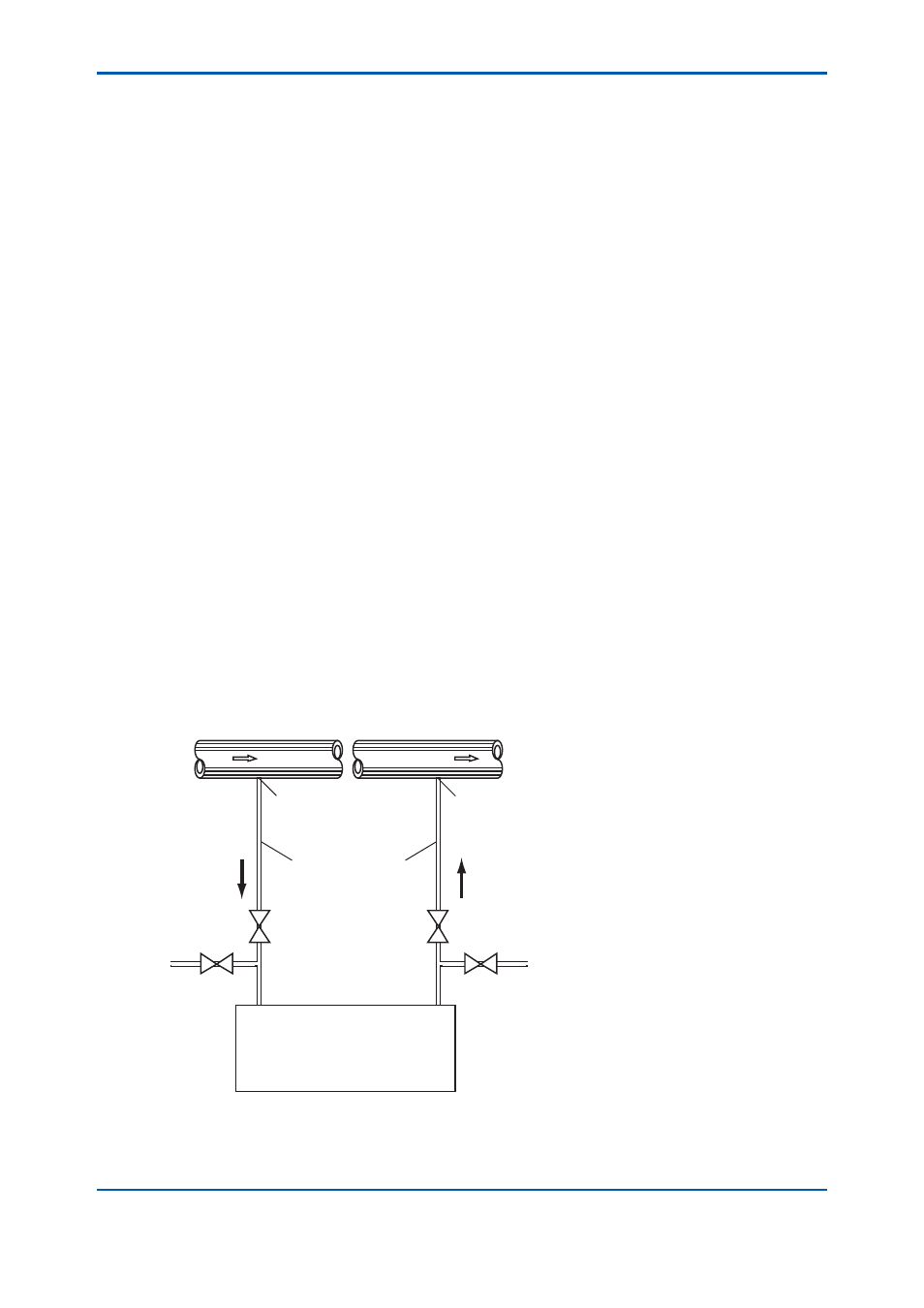

This piping conducts the measuring liquid to the sampling unit. The main process pipe should have

two sampling taps (sample inlet and sample return) as shown in Figure 3.14. The sample conduit

from the sample inlet is connected to ‘SAMPLE IN’ of the sampling unit and the other conduit from the

sample return to ‘SAMPLE OUT’ of the sampling unit.

The piping procedure is as follows:

(1) Select the tap locations for the sample inlet and the sample return to make the pressure

difference between them become at least 0.1 MPa.

(2) The pipe length between the sample inlet and the SAMPLE IN should not exceed 10 m. Use

stainless steel pipe of nominal diameter 15 mm or Sch 40 to 80.

(3) Install stop valves and drain valves near the sampling unit.

Sampling unit

for vibration type density meter

Drain valve

Drain valve

Sample conduits

(10 m max.)

Main process pipe line

Tap valve

Stop valve

P

in

(Pressure at inlet)

2 MPa > P

in

3

out

+ 0.1 MPa)

P

out

(Pressure at outlet)

Figure 3.14

Sample Liquid Conduits

(4) Avoid sharp bending of the pipe to prevent accumulation of sludge.